The clamps are distinguished by their load rating. In some cases, gas service loads could be less than loads in liquid service for the same pipe size. This would allow you to use a light duty clamp.

Resources

Resources

How much displacement can be accommodated on a hanging clamp pipe support?

It depends upon which typeof hanger you are using the clamp with and the amount of movement and the distancebetween the pipe and the nearby structural attachment point. On a variablespring, it is designed to accommodate 4 degrees of movement as a general rule.

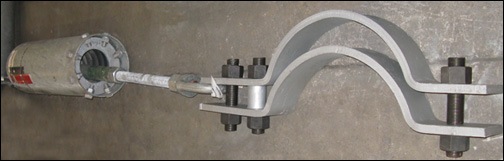

G-Type Variable Spring Clamp Assembly Supporting a Pipe in the Field

How does one accommodate horizontal displacement of a pipe support?

Guides or axial stops aretypically used to accommodate horizontal displacement.

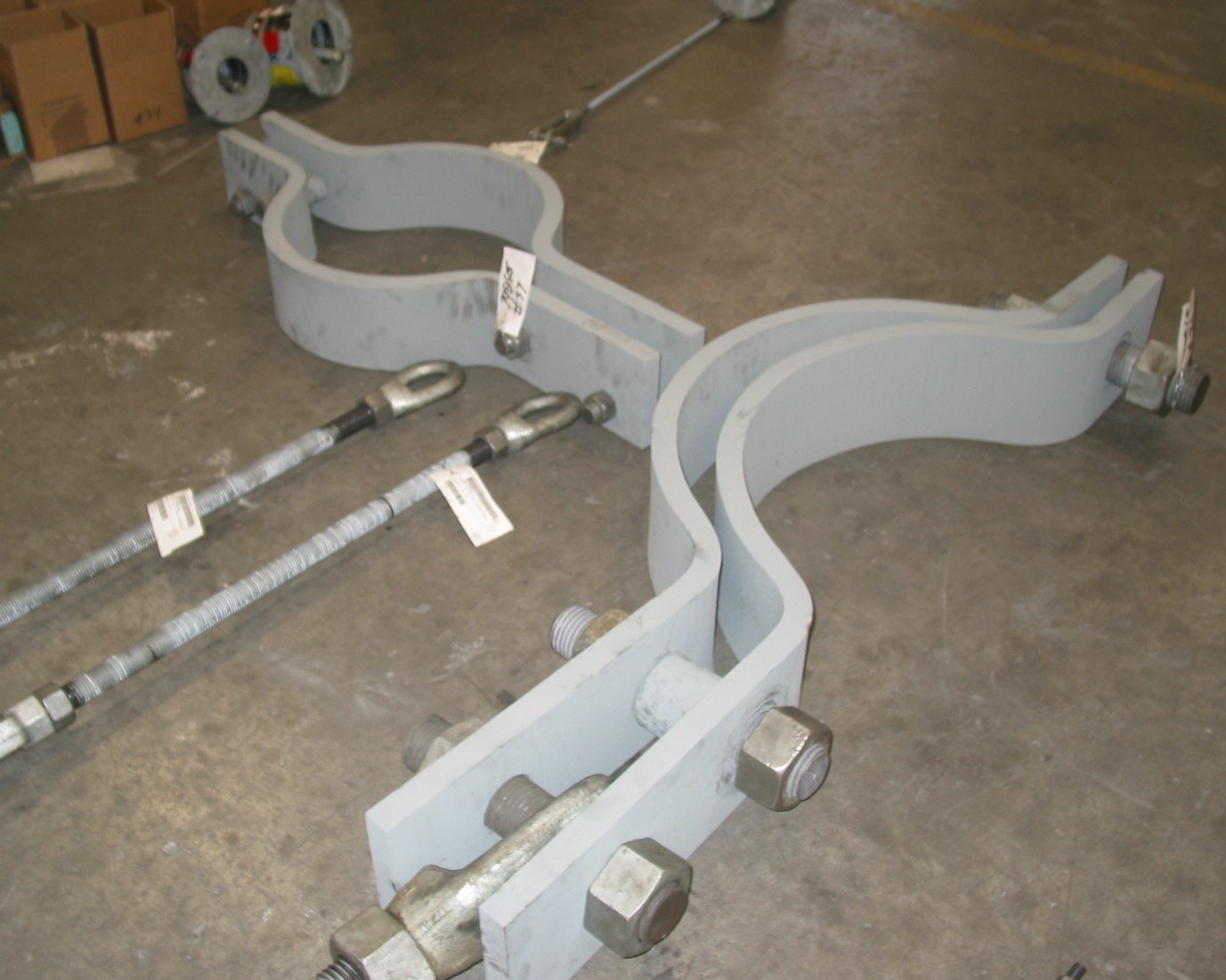

Cold Insulated Pipe Anchors with Axial Stops

What is the axial restraint between the foam insulation and a pipe clamp?

Axial restraint is usually the clamping forceand in case axial load is considerably higher, axial stops are welded to theinside of the clamp to prevent axial movement of the insulation within thesupport.

Cold Insulated Pipe Anchors with Axial Stops

Where the clamp has the PTFE applied directly, do you require a mating material on the pipe or a special surface preparation on the pipe?

No, a mating material is not required on the pipe.

Hold Down Pipe Clamp Designed with PTFE Material

Do the Bolts require a certain Torque level? If so how is this accomplished?

On some clamps, a certain torque level isrequired. It really depends on the application. The torque levels can be foundin the MSS standards which we utilize for pipe support design.

Why are the “wings” so long on the riser clamp?

The “wings” on a riser clamp allows for lateral movement and steadying ofpipe risers and also the wing length is a function of the available attachmentto our existing structural steel.

Riser Clamp

When should I use a clevis instead of a clamp?

Use theclevis when you do not need the clamp to be held in place during the movement.

PTP- 8 Type C Variable Spring Assemblies with a Rod, Clevis, and Hex Nuts

When should I use a Yoke clamp instead of a bolted clamp?

Yoke clamps have higher allowable loads than a bolted clamp. Secondarily, yoke style clamps are effective in areas where the bottom part of the pipe is in close proximity to structural steel or other pipe components.

In clamps that operate at higher temperatures, how do you specify the bolting torque?

For high temperature clamps, we recommend theuse of spring washers in order to prevent bolt relaxation.

Variable Spring with a High Temperature 3-Bolt Clamp

If we can exceed the pipe hoops stress when using clamps, how do we prevent the field guys from damaging the pipe?

You can provide them with clamp torque values onthe bolts of the clamp so as not to exceed the hoop stress of the pipe.

3-Bolt Pipe Clamp Installed in the Field

We are using plastic composite piping especially offshore due to corrosion like glass reinforced piping. How do the clamps differ for these materials instead of steel or stainless?

The clamps do not need to support as heavy of aload in this case. The outer diameter of the piping should be the same as thesteel piping.

3 Bolt Carbon Steel Pipe Clamps

Why are pipe clamps on a horizontal pipe assembled with 45° bolting holes direction?

Pipe clamps are assembled that way so that adjacent pipes can be placed closer together.

What type of clamp finish (i.e. unfinished or galvanized) do you suggest to use if dry graphite lubricant is applied to the clamping surface?

Can clamps with a galvanized surface be welded to a steel structure (for support purpose) or the surface needs to be ground prior to welding?

The pipe clamps with a galvanized surface has to be ground back to avoid releasing toxic fumes.

Riser Clamp with Hot-Dipped Galvanized Finish

Is the use of pipe clamps recommended for vibrating piping systems?

You can use them if the pipe clamps are linedwith neoprene or Fabreeka® or any other vibration dampening pad.

Three-Bolt Pipe Clamp

Clamp with insulation may be the source of water ingress, which may lead to corrosion. How do you tackle that situation?

One methodof reducing the corrosion between our pipe surface and our clamp surface is touse neoprene lining that does not absorb water.

Neoprene Lined Pipe Clamp

In the design of the three bolt clamp, are the top bolts smaller or is the single bolt connection adequate to retain proper clamping?

Are the loads on customized units stamped on the clamp?

No, they are not provided with the load on theclamp. We recommend you keep a log book in order to keep track of the supportswithin your piping system, along with their loads and movements.

Custom Designed Pipe Clamp-Guides

What is the major benefit or reason for using a yoke pipe clamp as opposed to regular two bolt pipe clamp?

The mainbenefit is that the yokeclamp can support a greater amount of load. Additionally, the lower portionof the clamp does not significantly protrude beyond the pipe O.D. This isbeneficial in installations where clearance is an issue.

Yoke U-Bolt Pipe Clamps