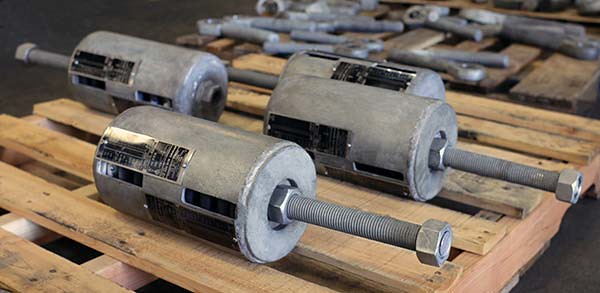

| Type: | Fig. 555 Sway Braces |

| Size: | 34-7/8” to 42-1/4″ |

| Material: | A36 carbon steel | Hot-dipped Galvanized |

| Design: | 17,827 lb. Ld. | 12″ Travel | 7,200 lb. Spring Rate |

PT&P custom designed Fig. 555 sway braces for the mechanical equipment supplier in Canada sound robust and tailored to specific requirements. Here’s a breakdown of the specifications:

- Material: Carbon steel, hot-dipped galvanized. This ensures corrosion resistance and durability, especially important for industrial applications where the environment can be harsh.

- Length Range: The sway braces vary in length from 34-7/8″ to 42-1/4″. This indicates flexibility in design to accommodate different distances between anchor points or points of attachment.

- Operating Load Range: Largest Sway Brace: Designed for an operating load of 17,827 lb. This suggests it’s meant for heavier-duty applications where substantial loads need to be supported.

- Smallest Sway Brace: Designed for an operating load of 200 lb. This indicates versatility in design, catering to lighter loads as well.

- Design Travel: Largest Sway Brace: Designed with a design travel of 12″ in either compression or extension. This accounts for significant movement allowance, essential for accommodating thermal expansion or contraction in the piping system.

- Smallest Sway Brace: Designed with a design travel of 9″ in either compression or extension. Though smaller, it still allows for adequate movement within the system.

- Spring Rate: Largest Sway Brace: With a spring rate of 7,200 lb. per inch, it demonstrates a higher stiffness, suitable for handling heavier loads while still providing the necessary flexibility.

- Smallest Sway Brace: With a spring rate of 1,800 lb. per inch, it offers a lower stiffness, ensuring smoother movement and accommodation of lighter loads.

These specifications indicate a thoughtful design process, considering factors such as load capacity, movement requirements, and environmental conditions. It’s a testament to PT&P’s expertise in providing tailored solutions for piping system needs.

It makes perfect sense that these sway braces require custom design and fabrication from PT&P due to their unique specifications exceeding standard parameters. By configuring each sway brace with a tailored combination of materials, spring coils, housings, and internal components, PT&P ensured that they could effectively handle the non-standard loads and movements specified for the project.

Customization is crucial in engineering projects, especially when dealing with varying environmental conditions, load requirements, and system configurations. By creating bespoke solutions, PT&P demonstrates their commitment to meeting the precise needs of their clients, ensuring optimal performance and reliability in the field.

This level of customization also highlights PT&P’s expertise and flexibility in adapting their products to meet specific project requirements, further solidifying our reputation as a trusted provider of engineered pipe support solutions.

PT&P REF. ORIGINAL POST 05152018