How a New Design was Developed During an Emergency Shut Down

View / Download Technical Bulletin (PDF)

Piping Technology & Products designed and manufactured new pipe supports for high-temperature pipelines at an existing power plant in August of 2002. This new design was the product of a customer’s urgent need during an emergency shut-down and the unique pipe support requirements. The original large-bore pipe supports on this high-energy pipeline were not optimally designed for the key operating conditions and as a result, failed to support the pipelines during their thermal movements. The previously supplied OEM pipe supports did not prevent (or insulate) heat transfer from the pipelines to the supporting pipe rack steel. These issues led to the plant shut down due to safety and operational considerations by the client and we were called to help.

PT&P was called in after the original supports failed again. Upon our field service technicians’ inspection, we recommended a new design brought on by the unique requirements of installation and time constraints. The power plant was in critical condition and needed a specialized minimum downtime “plan-of-action.” PT&P’s engineering and manufacturing teams worked quickly on the new design.

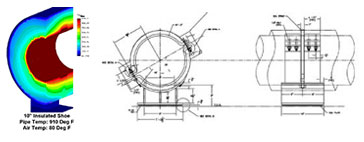

Engineering utilized FEA to both design the plate material and thickness required to support the various loads for the new pipe shoe and calculated the required frictional clamping force for line temperatures ranging from 650°F to 1100°F. The new supports were then manufactured on an expedited basis, supports were on-site for the client in less than 2 weeks from when the PO was placed. Our field service team traveled to the plant location and removed the failed OEM supports, and installed the newly designed supports which are still in operation today, and have replaced other OEM supports throughout their facilities nationwide.

Because the elevations of all the piping were fixed, PT&P had to develop a pipe support design that would dissipate heat and protect the PTFE 25% glass-filled slide plates (installed beneath the pipe shoe to reduce friction) from thermal damage by utilizing a design concept called “Natural Draft Air Cooling.” Natural Draft Air Cooling has several advantages over previous designs:

-

- Since the insulation does not carry any mechanical load with the new design, insulation material can be chosen solely based on its thermal properties. In this particular case, cyclic loading had caused insulation failure in the previous design. This problem was now alleviated.

- The new support provides effective restraint for multiple components of loads, X, Y, Z, Rotational, and Translational dependent on the location. In particular, Axial and Torsional loads are readily accommodated. These types of loads usually present difficulties for supports that rely on insulation to support a given load.

- The newly designed supports are easily installed in the field by attaching them to the pipe with bolted pipe clamps. Thus, there is no field welding.

PT&P REF. ORIGINAL POST 10102017 / Technical Bulletin 2009