Red, White and Blue Marks:

All constants are shipped with at least 3 color-coded rivets (red, white and blue).

Red: operating (HOT) position

White: installation (COLD) position

Blue: over travel (MAX AVAILABLE) position

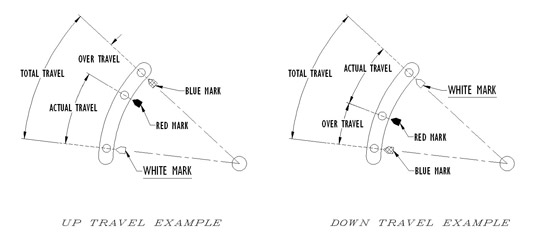

Below are sketches of one direction vertical travel:

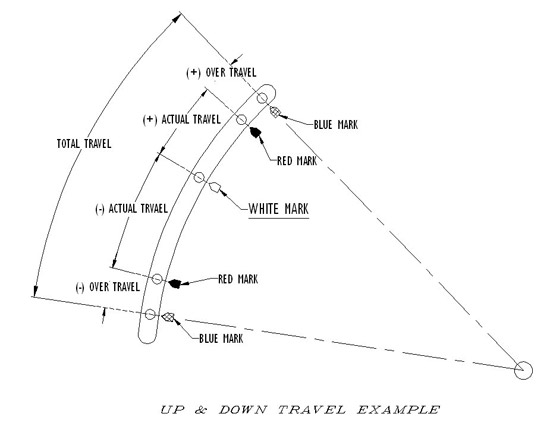

Below is a sketch of dual direction vertical travel: