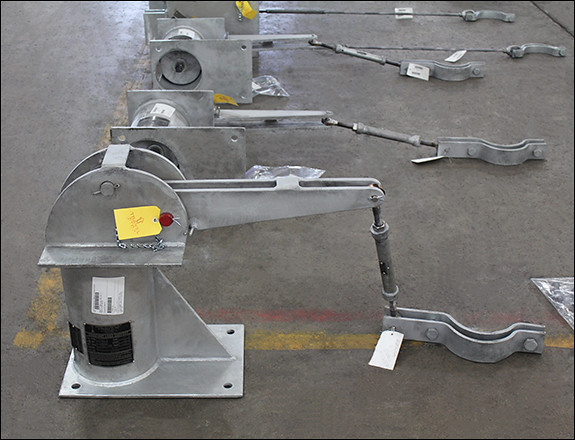

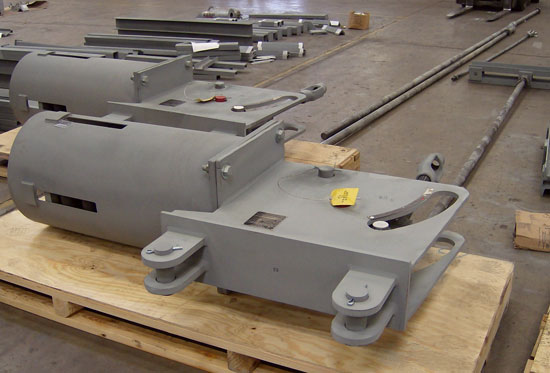

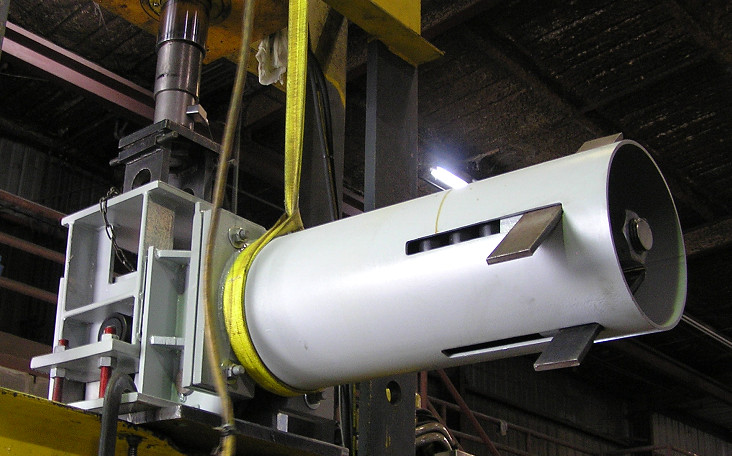

| Type: | Constant Spring Supports |

| Size: | PTP 200 C-Type Double Suspension |

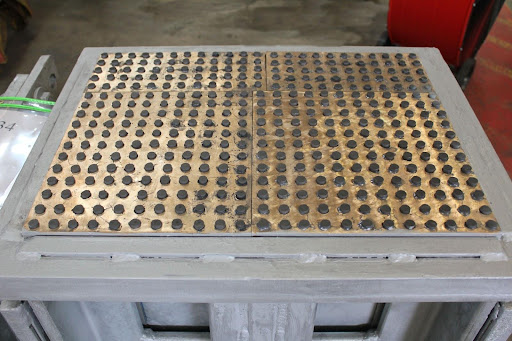

| Material: | Hot-dipped Galvanized Carbon Steel | Epoxy Coated Springs |

| Load: | 8,000 lb. – 19,000 lb. | Upward Movement: 6″ – 9″ |

| Testing: | Standard Load and Travel Test |

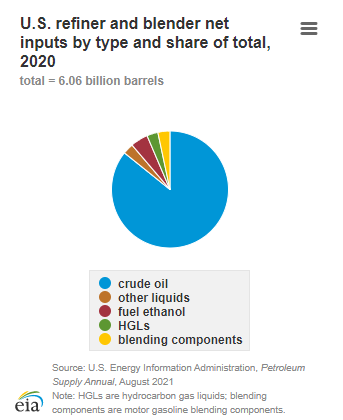

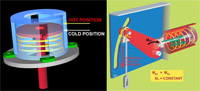

PT&P designed twelve constant spring support assemblies for a chemical plant in New Jersey. The assemblies will be used as replacements in a recuperator "up-leg" and "down-leg" application in conjunction with custom cross-over supports previously fabricated by PT&P. Physical sizes of these constant assemblies range from 18-1/2" x 22" x 64" to 18-1/2" x 26" x 83". Operating loads range between 8,000 lb. – 19,000 lb. and each allows for upward movement between 6" – 9". The spring coils are coated with epoxy instead of the standard neoprene coating. Standard load and travel tests were completed prior to shipment.

Constant spring supports find applications in various fields and can be made from diverse materials tailored to specific end applications. These supports are integral in industries such as petrochemicals, LNG, refining, power generation, steel mills, and geothermal plants, among others. In the past, obtaining a custom-designed constant spring support posed a significant challenge in terms of both design and manufacturing, with lead times extending to a minimum of 6-8 weeks.

Through a dedicated focus on manufacturing optimization and employing a design-centric engineering approach, we have successfully reduced the required manufacturing time by more than half. Now, the process of acquiring custom constant spring supports is significantly streamlined. In fact, we are capable of fulfilling emergency orders in less than 24 hours, taking into account the client’s location and urgent requirements.

PT&P REF. ORIGINAL POST 01232017