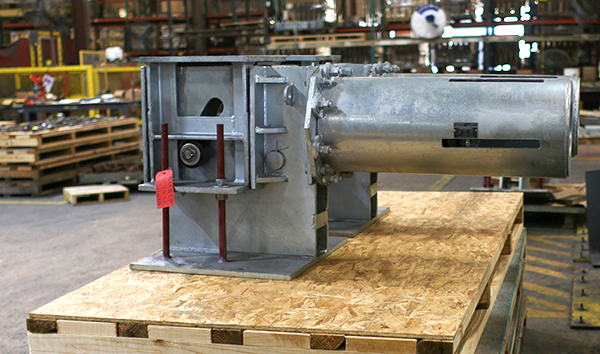

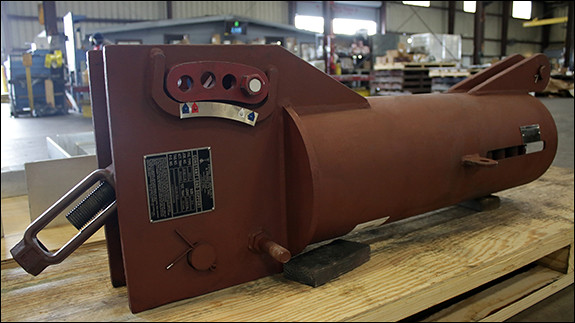

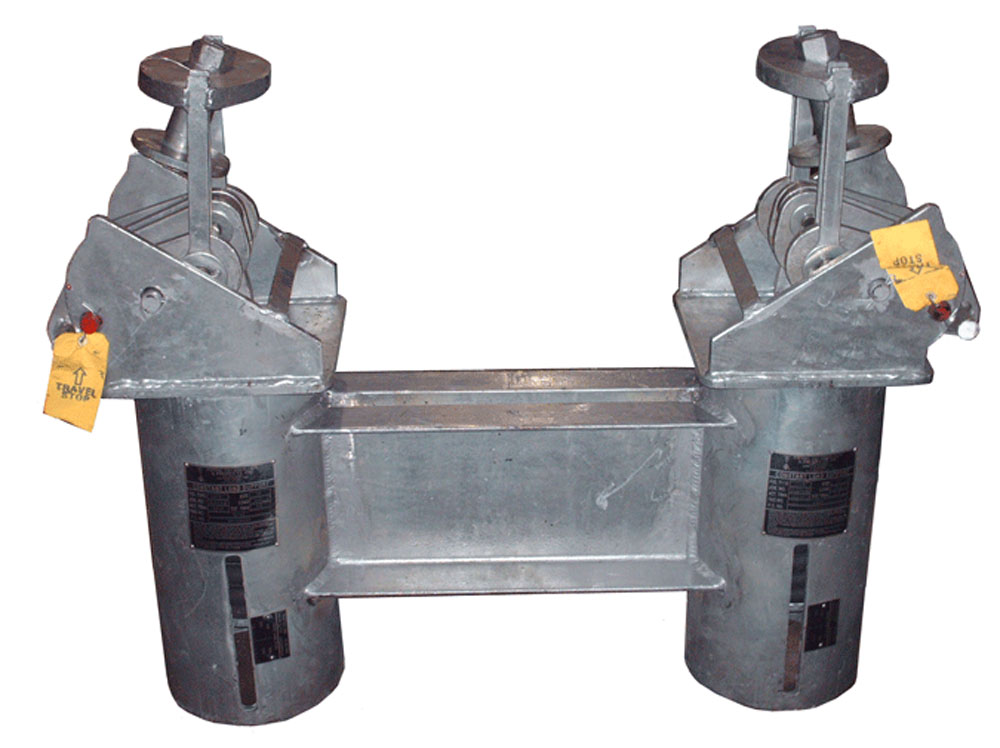

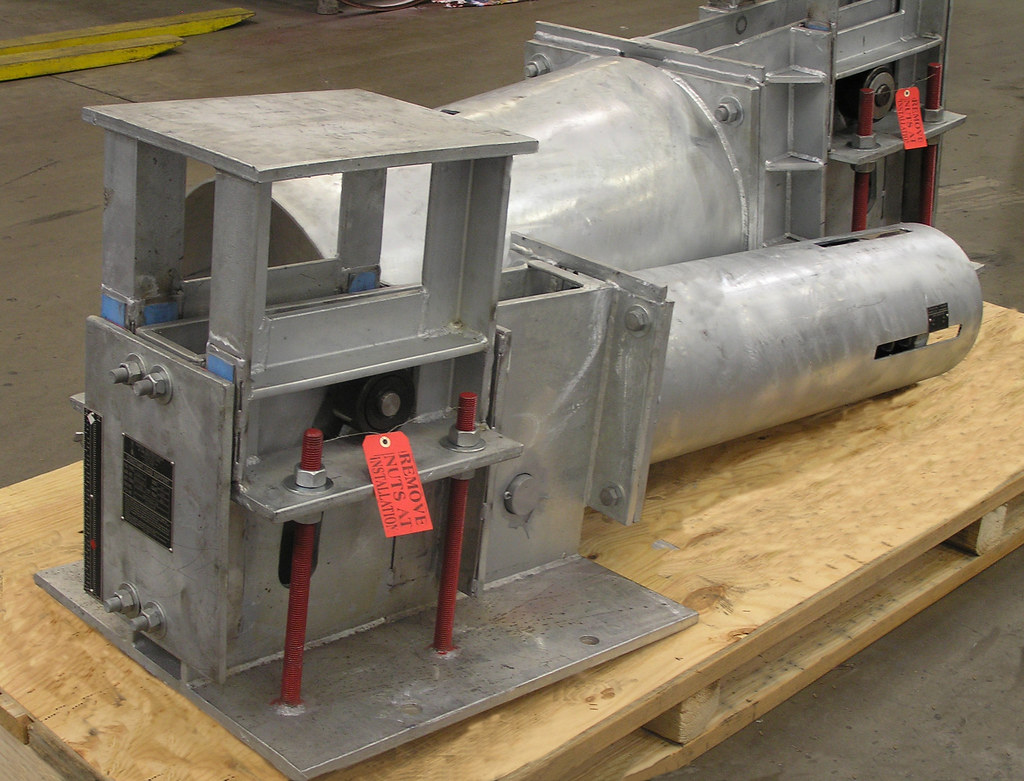

| Type: | Constant Spring Supports |

| Size: | 35-7/16″ Height & 75-3/4″ Length |

| Material: | A36 Carbon Steel with HDG | 304 Stainless Steel |

| Design: | 9″ Total Travel at 979°F | Operating Load 6,183 lb. |

| Testing: | Hydro tested at 6,744 lb. |

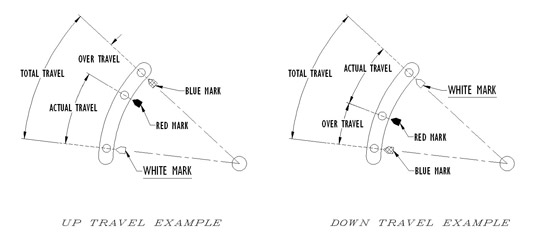

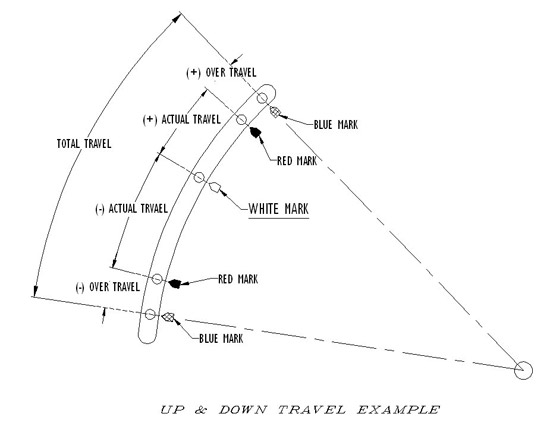

These 200 U-Type constant spring supports with slide plates were designed by PT&P for a plant in Texas. They are fabricated from A36 carbon steel with an HDG finish and are typically designed for vertical movement only. However, when there is lateral or axial movement in the piping system, slide plates can be used in conjunction with these constants. In this instance, graphite slide plates are bolted to the constant’s load flange and used with an upper slide plate manufactured from 304 stainless steel with a mirror finish. The upper slide plate can be welded to the base of a pipe shoe, trunnion, or the saddle of a pressure vessel. Each of the constant spring dimensions are 35-7/16″ in height and 75-3/4″ in length. They are designed for a piping system with 9″ of total travel at 979°F and an operating load of 6,183 lb. Each of these units were load tested to meet the hydro test load of 6,744 lb. before shipment.

Products such as these are used in many different kinds of plants all over the world including refineries, renewable diesel plants, chemical plants for operations such as propane/propylene splitter units, and power plants. We have the ability to custom design and manufacture constants for specific loads and various environmental conditions. A point to note, we provided similar constant spring supports supporting loads over 150,000 lb. for crude oil processing at one of the largest refineries in the world just last year (view this project). Petroleum refineries change crude oil into products such as jet fuel, gasoline, polypropylene, polyethylene, propane, sulfur, carbon black feed, and diesel that can be used for transportation, heating, feedstocks for making other chemicals, generating electricity, renewable energy, and paving roads. Constants use a spring coil (or series of coils) to accommodate pipe movement from the initial (installed) condition to the final (operating) condition of the piping system. For all constant spring supports there is no difference in load and the supported load will remain uniform throughout the deflection cycle. Learn more about constant spring supports

PT&P REF. ORIGINAL POST 01122018