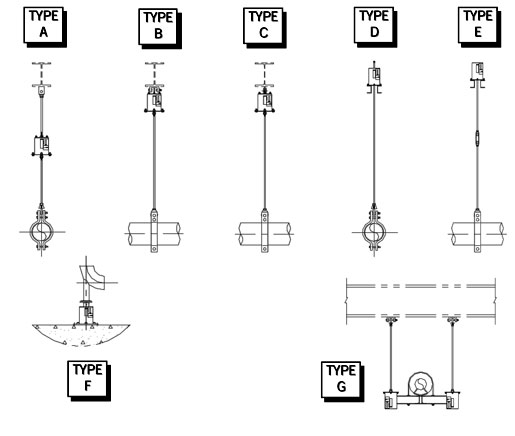

PT&P designed these G-Type variable spring support assemblies, along with a 24" diameter pipe shoe and hanger, for an oil and gas refinery in one of the largest refineries in Texas that was also the recipient of the American Fuel Manufacturers 2022 Innovation award. Our variables were for the refinery coker unit, which typically converts the residual oil from the vacuum distillation column into low molecular weight hydrocarbon gasses, naphtha, light and heavy gas oils, and petroleum coke.

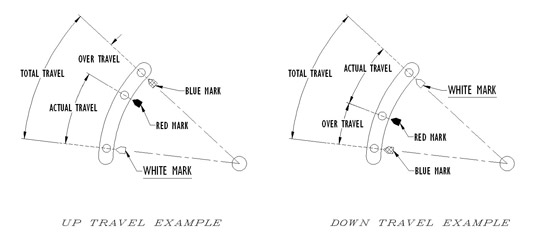

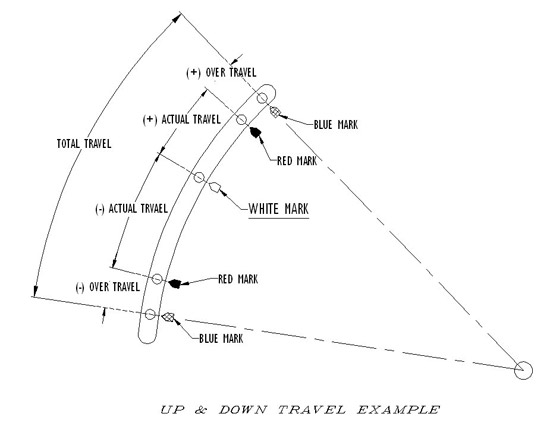

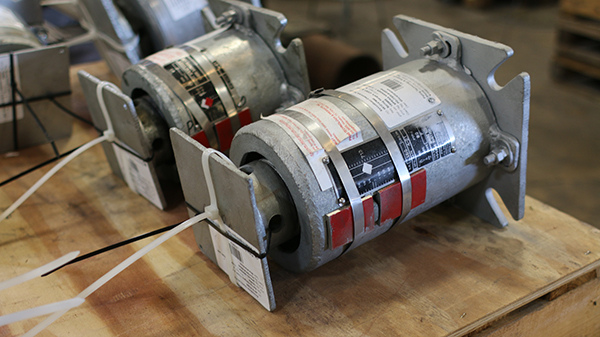

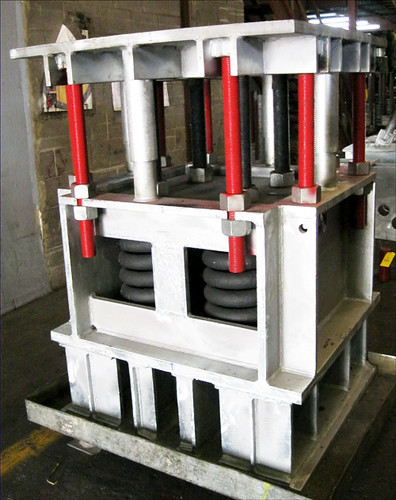

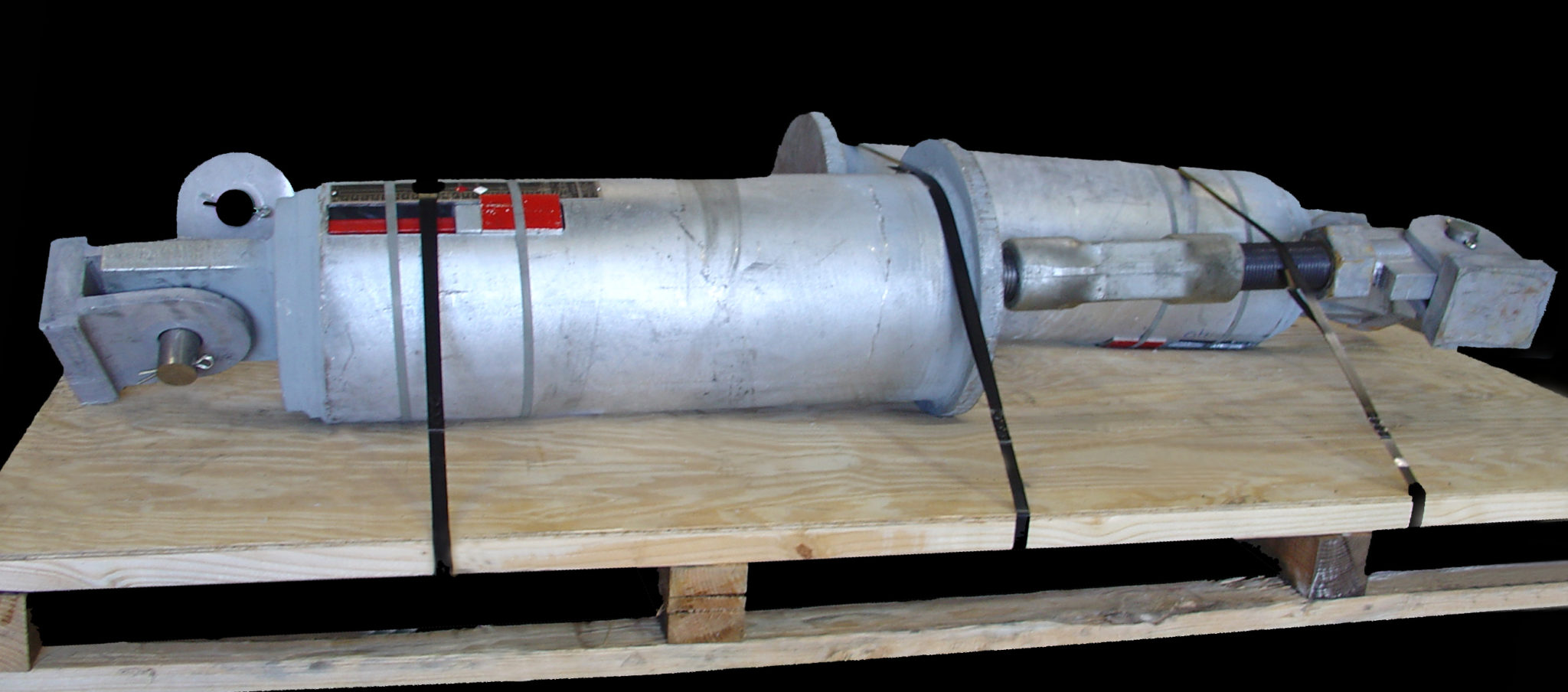

Each variable spring support assembly was designed with a center-to-center of 36" and an elevation difference of up to 72". The spring supports consist of a G-type variable spring, all threaded rods, clevis, lifting lugs, welding lugs, and clevis pins. They are designed with an operating load range from 1,700 lb. to 10,500 lb. and a movement range of .02" to .19" up or down. Standard load and travel testing was completed before shipment.

The refinery was originally constructed in the 1930s. PT&P and our subsidiaries have deep experience with maintenance and replacement work at existing facilities to keep them running and producing for our clients. Our field service teams are available to do an audit, inspection, or replacements of variable spring cans based on your needs.

PT&P REF. ORIGINAL POST 08092016