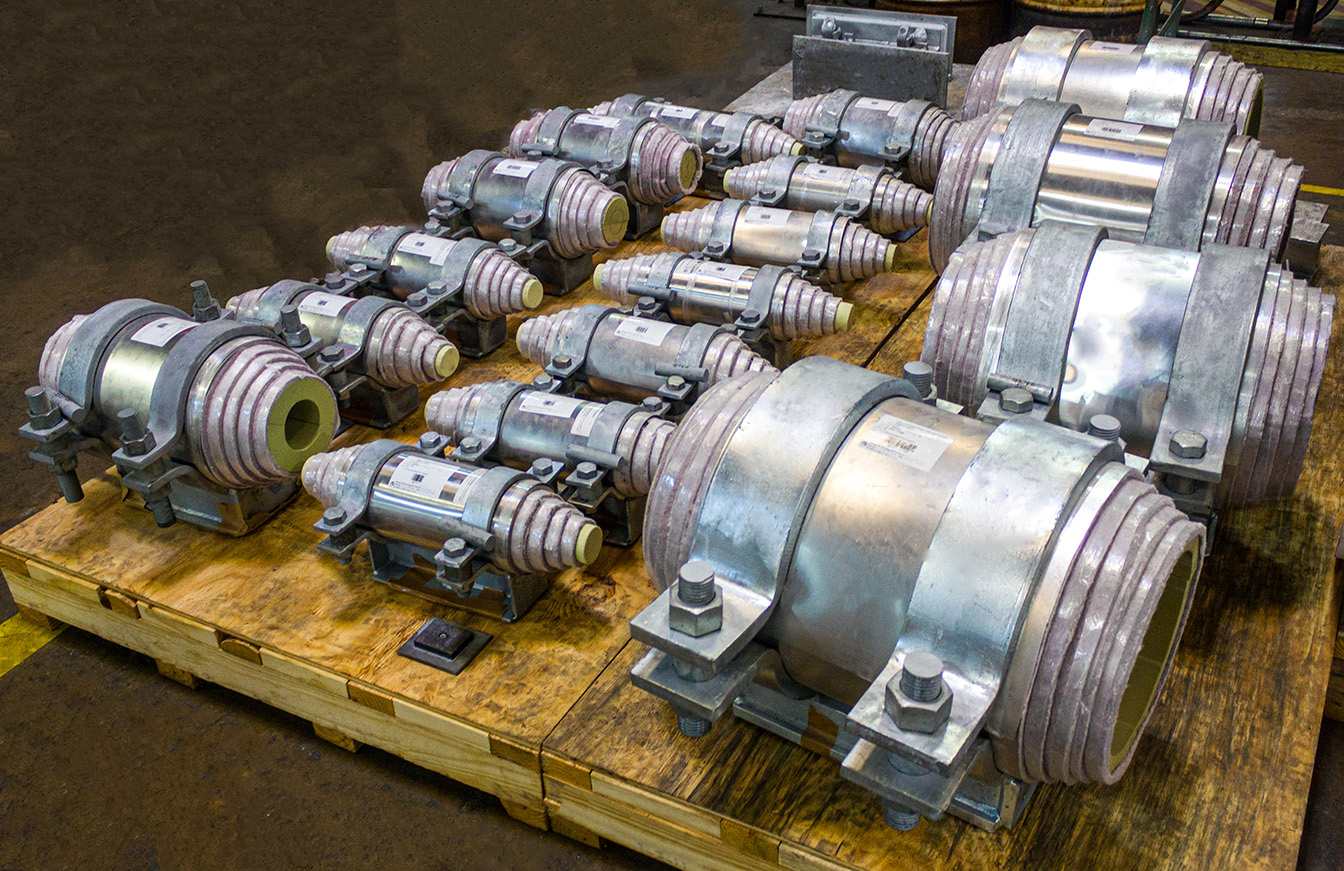

| Type: | Insulated Pipe Supports “Cold Shoes” |

| Material: | CS | 304L SS | Micarta® Insulation |

| Size Ranges: | 12-18″ L | 6-15″ W | 6-40″ H | 8-24″ Dia. |

| Design: | -320°F | Testing: PMI | Q.C. | MTR’s Provided |

PT&P custom designed insulated supports for a cryogenic pipeline at an LNG facility in Australia. They are fabricated with 304L stainless steel plates and Micarta® G-10 insulation. Micarta® is designed to prevent LNG temperatures of -320°F from transferring to the base and surrounding pipe rack steel. The base plates are fabricated from carbon steel. These pipe saddles are designed to support pipes with dimensions ranging from 12″-18″ in length, 6″-15″ in width and 6″-40″ in height. The nominal pipe size range is 8″-24″ diameter. MTR’s were provided and non-destructive testing (PMI) was performed, along with standard Q.C. inspection prior to shipment.

As a key partner for many LNG projects globally, a number of our designs and products have been installed in various parts of the LNG facilities. They include:

- Bird Screen

- Constant Assemblies

- FEA/Engineering Services

- Expansion Joints Metal Bellows

- Fabricated pipe shoes, guides, anchors

- Field Services

- Flanges, Strainers, paddle blinds, bleed rings

- Hold-down clamps

- Misc. Steel fabrication

- Orifice plates

- Pipe Hanger Hardware

- Restriction orifice plates

- Slide bearing plates

- Snubbers/Sway braces/Sway struts

- Spray Nozzles

- Varibales Assemblies

- Wear Pads

- Troughs and Shrouds

- Instrument spports

- Portable Hinges/Manways

The current LNG production climate has had significant growth driven by increasing global demand for cleaner energy sources. Major LNG-producing countries, such as the United States, Australia, and Qatar, continue to invest in expanding their liquefaction capacity to meet this rising demand. Advancements in technology and innovation improve the efficiency and cost-effectiveness of LNG production. We have been a part of these efforts because of our breadth and depth of experience in LNG. Most recently we completed design, manufacture, and delivery of over 200 LNG troughs over 40 feet long to meet the newly established FERC requirements around spillage.

PT&P REF. ORIGINAL POST 08202018