Tag: pipe support

Thermoplastic Isolator (TPI) – Technical Information

What is Thermoplastic Isolator (TPI)?

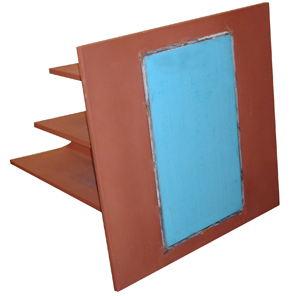

Thermoplastic isolators provide optimum support and eliminate pipe contact with the supporting steel.

- Moisture/water can be trapped between the pipe and support, which can initiate corrosion of the pipe

- In addition, when TPI is placed between the pipe and the supporting structural steel, it can prevent cathodic reaction

Iron + Water + Oxygen = Rust ➞ Corrosion

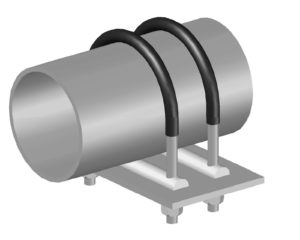

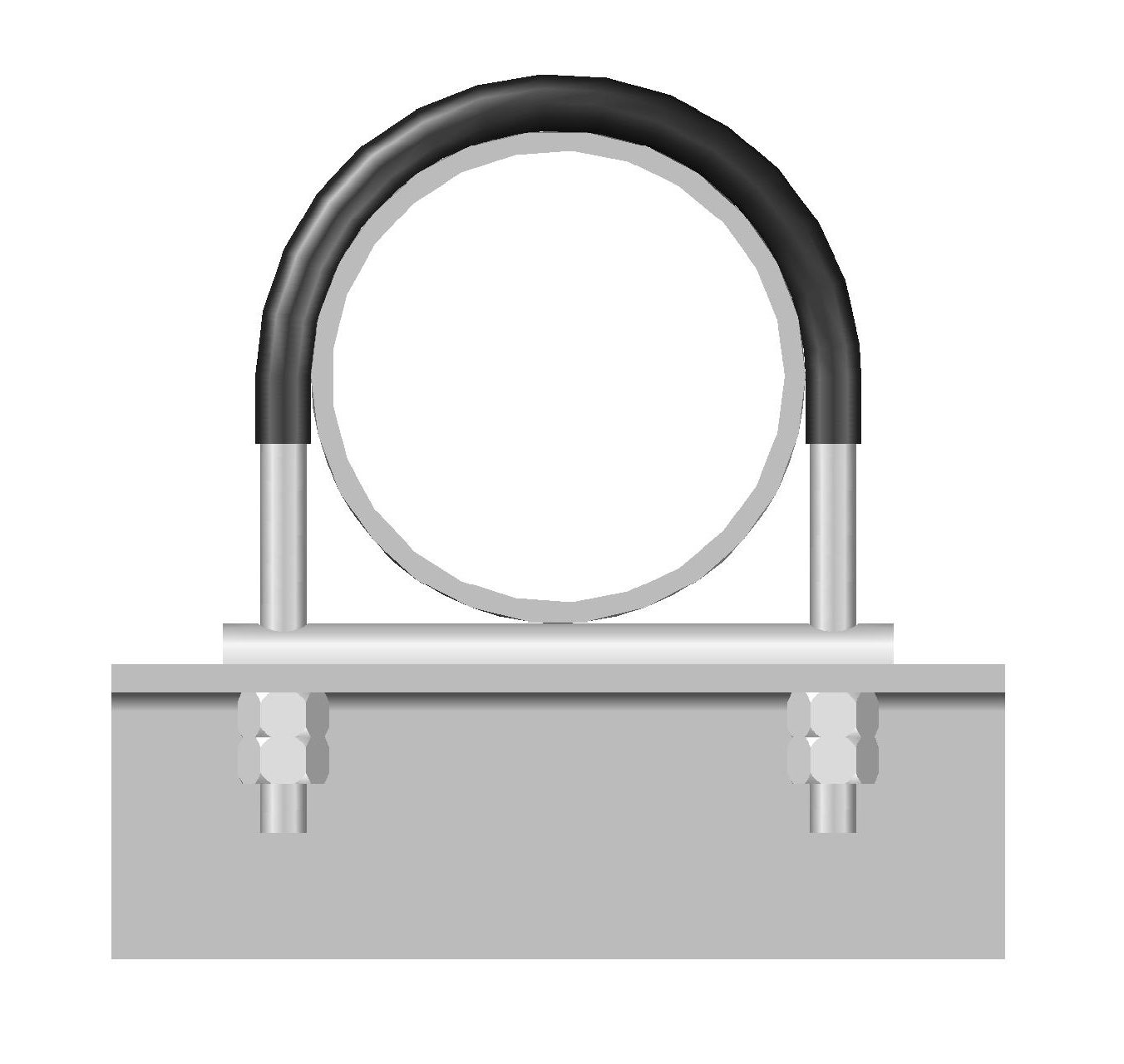

Piping Technology & Products can fabricate TPI designed for use with u-bolts. Our u-bolts, have a hot-dipped galvanized finish and are coated with Polyshrink. The Polyshrink acts as a barrier between the u-bolt and the pipe to prevent corrosion, and it also adds protection.

|

|

|

Benefits of Thermoplastic Isolator (TPI):

- TPI has a very high compressive strength

- It is subject to very little “creep” over the period of time

- TPI is easy to fabricate

- Cutting and drilling holes can be easily done

- Easy to Install

- Very economical when compared to the leading competitor

- It can be used with different types of pipe supports

Installation of TPI:

TPI can be placed or attached to structural steel by three different methods.

- Self-tapping screw or bolting

- Double-sided adhesive tape

- With u-bolt

Common Industry Application:

- Petrochemical plants

- Refineries

- LNG plants

- Offshore platforms

- Wastewater plants

- Parking garage

- Marine pipelines

Types of TPI:

There is a total of 3 different types of TPI available based on thermal properties.

- TPI White – Maximum Service Temperature 181°F

- TPI Amber – Maximum Service Temperature 340°F

- TPI Tan – Maximum Service Temperature 480°F

| TPI White | TPI Amber | TPI Tan | ||

| Property Value | ASTM Test | Imperial | Imperial | Imperial |

| Density | D792 | 0.0516 lb/in3 | 0.0458 lb/in3 | 0.047 lb/in3 |

| Tensile Strength | D638 | 11,000 psi | 17,000 psi | 16,000 psi |

| Tensile Modulus of Elasticity | D638 | 450 ksi | 500 ksi | 630 ksi |

| Elongation (At Break) | D638 | 30% | 60% | 40% |

| Flexural Modulus of Elasticity | D790 | 450 ksi | 500 ksi | 600 ksi |

| Flexural Strength | D790 | 13 ksi | 20 ksi | 25 ksi |

| Compressive Stress | D695 | 16 ksi | 22 ksi | 20 ksi |

| Coefficient of Friction | QTM 55007 | 0.25 | 0.42 | 0.32 |

| IZOD Impact (Notched) | D256 | 1 ft-lb/in | 0.5 ft-lb/in | 0.6 ft-lb/in |

| Rockwell Hardness | D785 | M 88 | M 115 | M 105 |

| Maximum Service Temperature | (Long Term) | 181ºF | 340ºF | 480ºF |

| Melting Point | D3418 | 347ºF | 410ºF | 644ºF |

| Coefficient of Linear Expansion | E831 | 47 µin/in/ºF | 31 µin/in/ºF | - |

| Flammability Rating | UL94 | HB | V-0 | V--0 |

| Electric Strength | D149 | 450 V/mil | 830 V/mil | 480 V/mil |

Key Factors in choosing PT&P’s Thermoplastic Isolator over Competitors:

- All suppliers of plastic components for these types of supports, purchase raw materials from some of the same sources

- PT&P’s TPI is equivalent to competitors, but the price of TPI is much lower

- In addition, TPI can be tested in any independent lab

| Property Value | ASTM Test | TPI - White | Competitor |

| Density | D792 | 0.0516 lb/in3 | 0.0509 lb/in3 |

| Tensile Strength | D638 | 11,000 psi | 9,400 psi |

| Tensile Modulus of Elasticity | D638 | 450 ksi | 380 ksi |

| Elongation (At Break) | D638 | 0.3 | 30-60% |

| Flexural Modulus of Elasticity | D790 | 450 ksi | 400 ksi |

| Flexural Strength | D790 | 13 ksi | 13 ksi |

| Compressive Stress | D695 | 16 ksi | 15 ksi |

| Coefficient of Friction | QTM 55007 | 0.25 | 0.25 |

| IZOD Impact (Notched) | D256 | 1 ft-lb/in | 1 ft-lb/in |

| Rockwell Hardness | D785 | M 88 | M 88 |

| Maximum Service Temperature | (Long Term) | 181ºF | 181ºF |

| Melting Point | D3418 | 347ºF | 329ºF |

| Coefficient of Linear Expansion | E831 | 47 µin/in/ºF | 54 µin/in/ºF |

| Heat Deflection Temperature, 264 psi | D648 | 250ºF | 220ºF |

| Flammability Rating | UL94 | HB | HB |

| Electric Strength | D149 | 450 V/mil | 420 V/mil |

| Result from above comparison, both products are equivalent | |||

| Property Value | ASTM Test | TPI – Amber | Competitor |

| Density | D792 | 0.0485 lb/in3 | 0.0462 lb/in3 |

| Tensile Strength | D638 | 17,000 psi | 16,500 psi |

| Tensile Modulus of Elasticity | D638 | 500 ksi | 500 ksi |

| Elongation (At Break) | D638 | 0.6 | 30-60% |

| Flexural Modulus of Elasticity | D790 | 500 ksi | 500 ksi |

| Flexural Strength | D790 | 20 ksi | 20 ksi |

| Compressive Stress | D695 | 22 ksi | 22 ksi |

| Coefficient of Friction | QTM 55007 | 0.42 | 0.42 |

| IZOD Impact (Notched) | D256 | 0.5 ft-lb/in | 0.5 ft-lb/in |

| Rockwell Hardness | D785 | M 115 | M 112 |

| Maximum Service Temperature | (Long Term) | 340ºF | 340ºF |

| Melting Point | D3418 | 410ºF | 410ºF |

| Coefficient of Linear Expansion | E831 | 31 µin/in/ºF | 31 µin/in/ºF |

| Heat Deflection Temperature, 264 psi | D648 | 400ºF | 400ºF |

| Flammability Rating | UL94 | V-0 | V-0 |

| Electric Strength | D149 | 830 V/mil | 830 V/mil |

| Result from above comparison, both products are equivalent. | |||

| Property Value | ASTM Test | TPI - Tan | Competitor |

| Density | D792 | 0.047 lb/in3 | 0.047 lb/in3 |

| Tensile Strength | D638 | 16 ksi | 16 ksi |

| Tensile Modulus of Elasticity | D638 | 630 ksi | 500 ksi |

| Elongation (At Break) | D638 | 0.4 | 0.2 |

| Flexural Modulus of Elasticity | D790 | 600 ksi | 1000 ksi |

| Flexural Strength | D790 | 25 ksi | 25 ksi |

| Compressive Stress | D695 | 20 ksi | 20 ksi |

| Coefficient of Friction | QTM 55007 | 0.32 | 0.4 |

| IZOD Impact (Notched) | D256 | 0.6 ft-lb/in | 1.0 ft-lb/in |

| Rockwell Hardness | D785 | M 105 | M103 |

| Maximum Service temperature | (Long Term) | 480ºF | 480ºF |

| Melting Point | D3418 | 644ºF | 644ºF |

| Coefficient of Linear Expansion | E831 | - | - |

| Heat Deflection Temperature, 264 psi | D648 | 320ºF | 320ºF |

| Flammability Rating | UL94 | V--0 | V--0 |

| Electric Strength | D149 | 480 V/mil- | 480 V/mil- |

| Result from above comparison, both products are equivalent. | |||

What factors go into calculating Pipe Thickness?

When calculating your pipe thickness, you want to take a few parameters into consideration:

What is a steel washer plate?

Steel washer plates are components used on top of channels or angles to support pipe with rods or U-bolts.

What is a pig receiver?

A pig receiver is a device that “catches” the cleaning device (“pig”) after it has passed through the pipeline.

Pig Receiver with a 24″ Dia. Minor Barrel

What is a pig launcher?

A pig launcher is a device which uses a pressurized container to shoot a cleaning device (“pig”) through the pipeline to perform a variety of functions including cleaning, monitoring, and maintaining of the pipe.

Pig Launcher and Receiver

What is a pipe guide?

A pipe guide can be categorized into two types. The first is as a shoesupport attached directly to the pipe with external components which direct thepipe during the thermal deflection cycle. The second type of guide surroundsthe pipe and is attached to stationary structures, allowing the pipe to move.

Pipe Guide with Slide Plates

What is a j-rod on a pipe support?

When referring to constants, the j dimension refers to the diameter ofthe rod which transfers our load from the constant to the support component.(i.e. clamp, clevis, etc.)

Constant Drawing with J Dimension Shown

What is a cold shoe?

A cold shoe refers to a support component which incorporates an insulating material that attaches directly to the pipe and also functions as a load bearing component transferring the load to a point outside of the insulating enclosure.

Cryogenic Supports (Cold Shoes) with Permali Insulation

What happens if variable spring variability increases?

When the variabilityof a variable springexceeds the MSS standard of 25%, the designer's first option would be to lowerthe spring rate so that the difference in load with the same amount of movementwould be smaller than that associated with the higher spring rate. The designerwould continue this exercise until a variability factor of less than 25% isachieved.

What is a clevis and yoke?

A clevis and yoke refers to two components used when temporarily riggingpipes into position which consists of an adjustable strap which fits around thepipe. The clevis then attaches the temporary strap to our lifting mechanism.

What does variability mean in pipe supports?

Variability applies to variable spring supports and is basically a ratiobetween the difference in load and the operating load of the spring. Thedifference in load is a function of the spring rate and travel. Per MSS, themaximum recommended variability would be 25%. However, critical systems such asmain steam supports may require variability factors less than 25%.

What can I use to hold down insulation?

In general, insulation, whether for low temperature or high temperatureuse, is clad with a metallic sheet (usually aluminum) and that metallic sheetis held in place by either straps or wire at predefined intervals along thepipeline.

What is a spring support?

We refer to our spring supports as any assembly which includes a spring(either variable or constant) that can accommodate both a pipe load and a pipemovement.

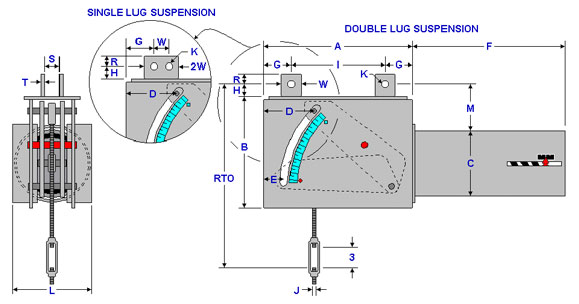

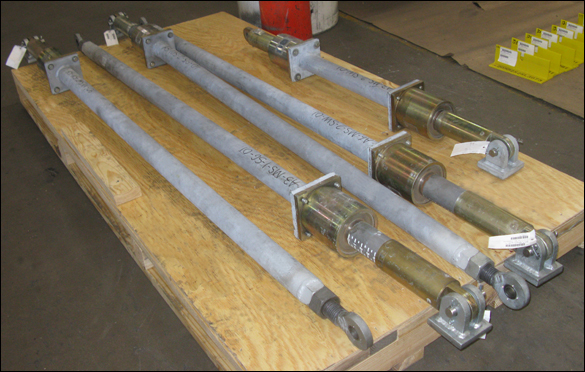

What are piping struts?

Piping struts,also referred to as sway struts, are devices used to restrain movement of piping in one direction while providing for movement due to thermal expansion or contraction in another direction.

Sway Struts with 3-Bolt Pipe Clamps

What is a pipe anchor support?

A pipe anchor support is a rigid device that completely restricts pipe movement in all three dimensions while bearing the weight, side, and thrust loads. It is designed to prevent essentially all pipe rotation and displacement at the point of application.

Cold Insulated Pipe Anchors with Axial Stops

What is a sway brace?

A sway brace is a device that is recommended for controlling vibration, absorbing shock loadings, guiding or restraining the movement of pipe resulting from thermal expansion, and bracing a pipe line against sway. They contain springs that provide a restraint force in both a tension and compression mode.

Sway Braces with Ball Joints

What is a riser clamp?

A riserclamp is a pipe clamp for thesupport of vertical pipelines, and they include separate load bolts, totransfer the piping load to the remainder of the pipe hanger assembly.

Riser Clamps

What is a hydraulic snubber?

A hydraulic snubber is a device that permits pipe deflection under normal operating conditions, but when subjected to an impulse load, such as an earthquake, water hammer, etc., the snubber becomes activated and acts as a rigid restraint torestrict pipe movement as a result of the unwanted impulse loading.

A hydraulic snubber includes a hydraulic fluid reservoir and cylinder to produce the restraint force when activated.

Hydraulic Snubbers with Protective Boots

What is a mechanical snubber?

A mechanical snubber is a device that permits pipe deflection under normal operating conditions, but when subjected to an impulse load, such as an earthquake, waterhammer, etc., the snubber becomes activated and acts as a rigid restraint to restrict pipe movement as a result of the unwanted impulse loading.

A mechanical snubber uses gears and springs to produce the restraint force when activated.

Mechanical Snubbers