Piping Technology & Products gives you 5 reasons on why we crush the competition.

Piping Technology & Products gives you 5 reasons on why we crush the competition.

Roller hangers are used for the suspension of pipe from a single rod where horizontal movement may occur because of expansion or contraction.

These PTP-1 F-Type variable spring assemblies fabricated from A-36 carbon steel, were custom designed to accommodate a height of 11-11/16″ while keeping the same spring rate. The F-Type variable is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The variables are designed for loads up to 6,500 lb. and a total upward travel of 5/16″.

Want to learn more about variable springs? Check out a recording of a past live webinar.

The designstandards that we utilize in the engineering and design of pipe supports atPiping Technology are the Manufacturers Standardization Society (MSS) standards as well as the AmericanSociety of Mechanical Engineers (ASME) standards.

PipingTechnology and Products is the name of our company specializing in pipesupports, pre-insulated supports, slide plates, snubbers, sway braces, and muchmore. In business since 1975, Piping Technology has over 35 years of experiencein the engineering and design of high-quality pipe supports. Piping Technologyis a parent company to four subsidiaries including U.S. Bellows, Sweco Fab,Fronek Anchor/Darling Enterprises, and Pipe Shields.

Piping Technology: 35 Acre Facility

Piping Technology & Products, Inc. attended the 8th annual ASME Plant Engineering, Inspection and Maintenance Trade Show at the Pasadena Convention Center in Pasadena, Texas on Thursday, April 22, 2010. Joel from Chevron stopped by the PT&P booth and won a Kodak C190 12mp digital camera. Congratulations Joel!

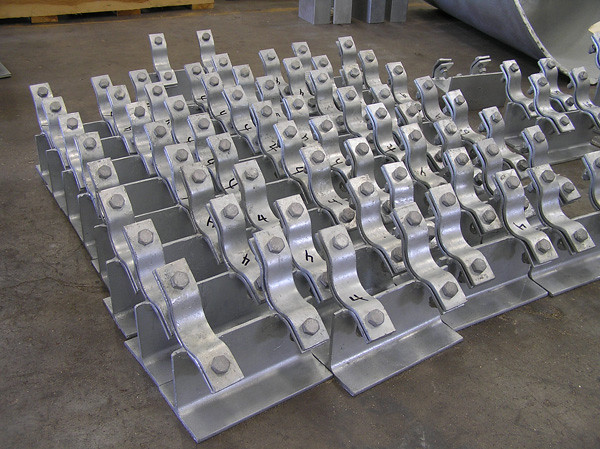

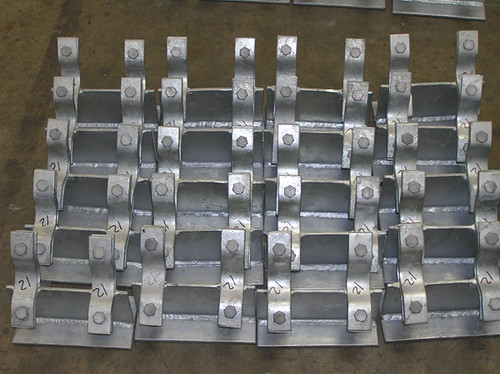

Piping Technology & Products, Inc. custom fabricated sixty bolt cradle supports in May 2006. The base was fabricated by welding two plates to form a “T.” This was used in place of a standard split “T.” By making simple modifications to a standard Figure 900 for two-inch pipe, such as heavier clamps and shortened base length, PT&P was able to meet the customer’s special requirements quickly and efficiently.

Do you require cradle supports for your current or future job? Get pricing today!

The specific temperature at which personnel protection equipment isrequired would be site specific. The average temperature where protectivemeasures would be incorporated would be about + 200 degrees Fahrenheit.

Piping Technology & Products, Inc., in conjunction with other sponsors, has completed the first pilot test of Radio Frequency Identification (RFID) technology for the receipt and tracking of pipe supports material at construction jobsites.

The RFID tags and RFID handheld reader used by Piping Technology & Products, Inc. at the Red Hills Power Plant.

The material shown here arrived from PT&P’s manufacturing facility in Houston, Texas with an RFID tag affixed to each pipe support assembly.

Piping Technology & Products, Inc. shipped approximately 150 pipe supports to the Red Hills Power Plant with radio frequency identification (RFID) chips affixed to each pipe supports. The RFID tags and RFID handheld reader were provided by SAT Safetrac. Field personnel were trained on the use of the new technology. The RFID-tagged pipe support assemblies were then received by field personnel. Videos of the RFID receiving process were taken for the purpose of comparative time and motion studies.

PT&P has a contract to provide the fabricated pipe supports and the cold shoes on a power plant in Puerto Rico. Imported liquid natural gas will be the primary fuel for the plant. PT&P cold shoes will be important to support the piping from the LNG storage tanks to the power plant. PT&P has worked on power projects in Rhode Island and Beaumont, Texas. Currently, PT&P is working on power projects in China, Malaysia and various sites in the United States.

Basic Engineers Auction Yields Manufacturing Machinery

A supplier of pipe supports, Basic Engineers (BE) of Johnstown, PA decided to close its business in late 1997. In May 1998, the company held an auction to liquidate BE’s manufacturing equipment. PT&P acquired the majority of Basic Engineers’ assets, including its test equipment for snubbers. For additional information on snubbers, please refer to our Mobility Test article.

Fall Open House Set For November 4

PT&P’s workforce of over 350 dedicated employees will welcome guests at this year’s Fall open house, from 11:30 a.m. to 3:30 p.m., Wednesday, November 4. The celebration will be at the plant: 3701 Holmes Rd. in Houston, Texas. Those who attend will be treated to a luncheon and have the opportunity to register for door prizes including a pentium computer, golf clubs and sports bags.

he U.S. Department of Energy, major E&C firms and electric utilities are building commercial-size power plants to evaluate new technologies and equipment to produce electricity from coal without harmful emissions. These plants are expected to produce operating data which will be used to design many of the power plants required in the twenty-first century.

Coal is an abundant fuel source in North America and the price is not as subject to political and economic changes around the world as most other fuels are. But coal’s toxic elements make it one of the most polluting fuels. The U.S. Department of Energy has supported research programs for a number of years leading to these current projects. They are pioneering better ways to burn coal or to convert it to gas. The processes must be both efficient and clean.

PT&P has been a major supplier to three of these projects: the Southern Company Services plant in Wilsonville, Alabama, the Tampa Electric project in Polk County, Florida, and the Sierra Pacific project in Nevada. PT&P along with its customers are helping to insure a stable energy supply for our nation.

The photograph above shows one of 72 of these supports fabricated by Piping Technology & Products, Inc. for shipment to Alaska. Note that the distance between the top pipe where other components are attached and the base the support rests on can be changed by selecting the holes for the arms. These removable supports are used during installation of pipelines. Pipe sections may have other permanent supports if the pipe is above ground or the lines may be underground.

Would you like to learn more about pipe supports? Visit out webinar archives today!

The photograph above shows a number of fabricated components of a piping system being marked for individual packaging before shipment to the construction site at a chemical plant. The markings correspond to the assembly drawings which are used during construction to assure the many little components are efficiently installed to meet a demanding schedule. Piping Technology & Products, Inc. prepared the detail drawings and fabricated all components for a series of four projects for chemical plants in USA.

Would you like more information on fabricated components? Check out our webinar archives!

Large fabricated pipe support being welded by one of Piping Technology’s welders. When it is completed it will be shipped to a major refinery in the Virgin Islands.

Do you need any type of fabricated pipe supports? Allow us to provide a quote!