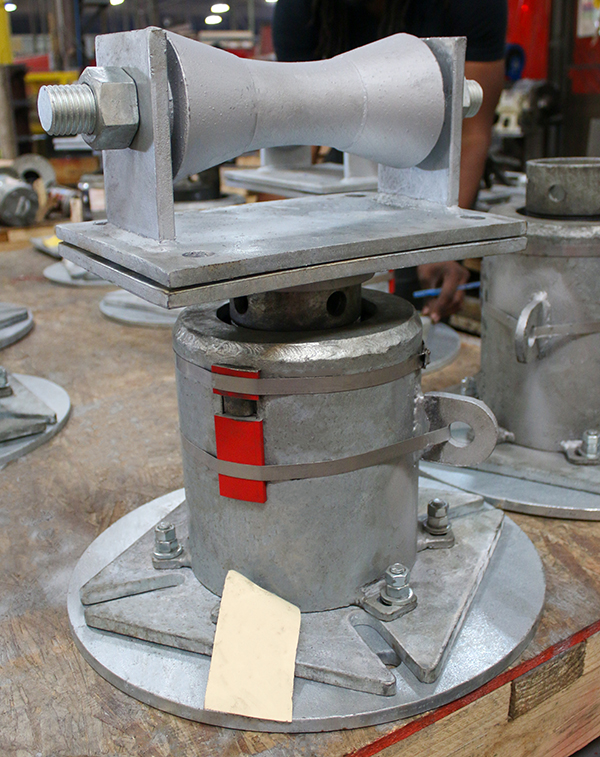

| Type: | Variable Springs w/ Rollers |

| Size: | Springs: 11.1/16″ H | Rollers: 24″ -36″ Dia. |

| Design: | 700-15,970 lb. Loads | 650°F Temp. |

| Material: | HDG Carbon Steel | Cast-iron |

| Testing: | Standard Load Testing & Q.C. Inspection |

Variables use coiled springs to support a load and allow movement. The resistance of the coil to a load changes during compression, which is why these devices are called “variables”. We offer a variety of different designs of variable spring pipe supports. View Variable Spring Supports Product Section.

For this application, the variable spring with rollers were used in natural gas compressor stations in Texas. Compressor stations are an essential part of a natural gas pipeline that moves natural gas from one location to another. At these stations, natural gas is re-pressurized and sent back into the pipeline system where it travels until the next compressor station. The location and distance between compressor stations is dependent on terrain, and the number of gas wells in the vicinity. Frequent elevation changes and a greater number of gas wells will require more compressor stations.

The compressor station, also called a pumping station, is the “engine” that powers a long-distance natural gas pipeline. As the name implies, the station compresses the gas (increasing its pressure) thereby providing energy to move it through the pipeline. The compressor is driven by a motor fueled by some of the natural gas bled from the pipeline. The size of the station and the number of compressors (pumps) varies, based on the diameter of the pipe and the volume of gas to be moved.

Piping Technology and Products and its subsidiaries provide products and services to this critical piece of the energy infrastructure with not only variable spring supports with rollers showcased here, but also with insulated supports, expansion joints, pipe shoes, guides, and anchors.

PT&P REF. ORIGINAL POST 02172020