The coefficient of friction of polish stainless steel slideplate is 0.1.

The coefficient of friction of polish stainless steel slideplate is 0.1.

The reason for the use of slide plates is to reduce thecoefficient of friction between two surfaces. So to use an unpolished steelsurface, defeats the purpose of reducing the coefficient of friction.

A bearing plate is also referred to as a slide plate. It is a component that can be fabricated from a variety of materials including graphite, PTFE, 25% glass filled, stainless steel, and bronzphite. The purpose of slide plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

Here at Piping Technology, we use a 2-part epoxy glue to chemically bondthe PTFE to its respective backing plate.

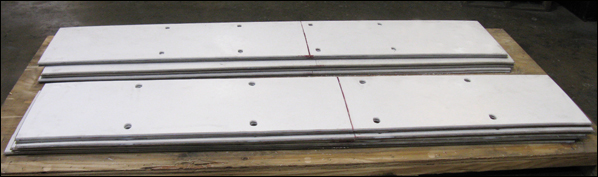

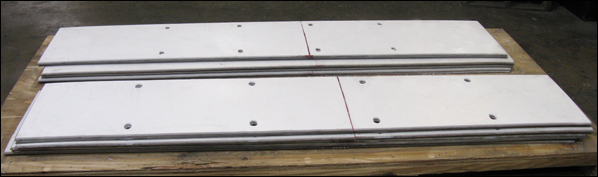

PTFE Slide Plate

A PTFEslide plate is simply a layer of PTFE, 25% glass filled material bonded to acarbon steel backing plate.

PTFE Slide Plate

For PTFE, 25% Glass Filled Slide Plates:Prior to Welding: Locate the slide plate base in the appropriate position on the existing steel surface. Place a protective covering on the PTFE, 25% glass filled. Where seal welding is not required, follow the diagram shown which indicates 1/8 inch thick fillet weld, 1 inch long every 4 inches around entire perimeter of the base. For welding, use GMAW 0.035 wire or SMAW 3/32 inch stick.Where full seal welding is required, use a similar pattern of welding until a full weld is obtained. This method will prevent damage to the PTFE, 25% glass filled. (A full weld will help prevent seepage of water between the slide bearing plate and the support structure.) Avoid overheating, which may destroy the bonding of the PTFE, 25% glass filled to the base plate.Installation in Concrete: Secure the top and bottom elements together with paper adhesive tape. Then attach the bottom element anchor bolts with wire to the form. After the bottom pour is made, repeat on top element. During the first expansive cycle, the tape will break. For Graphite and Bronzphite Plates – see link below:

The purpose of slide plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

A PTFE bearing pad is a slide plate made up of PTFE, 25% glass filled, material that provides a low coefficient of friction for most combinations of temperature and load. For most applications, PTFE, 25% Glass Filled, is adequate when the temperature is less than 400 degrees F.

PTFE is also know as polytetrafluoroethylene. It is used as a component of slide plates and functions as a low-coefficient of friction between a stationary support element and the moving pipe support component.

A slide plate is a component that can be fabricated from a variety of materials including PTFE, 25% glass filled, graphite, Bronzphite®, Marinite®, and stainless steel. The purpose of slide plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

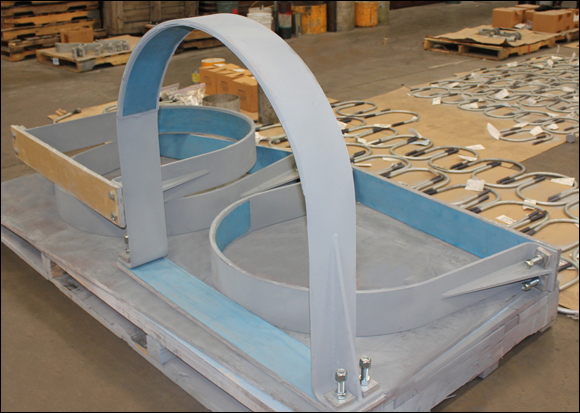

Graphite Slide Plates