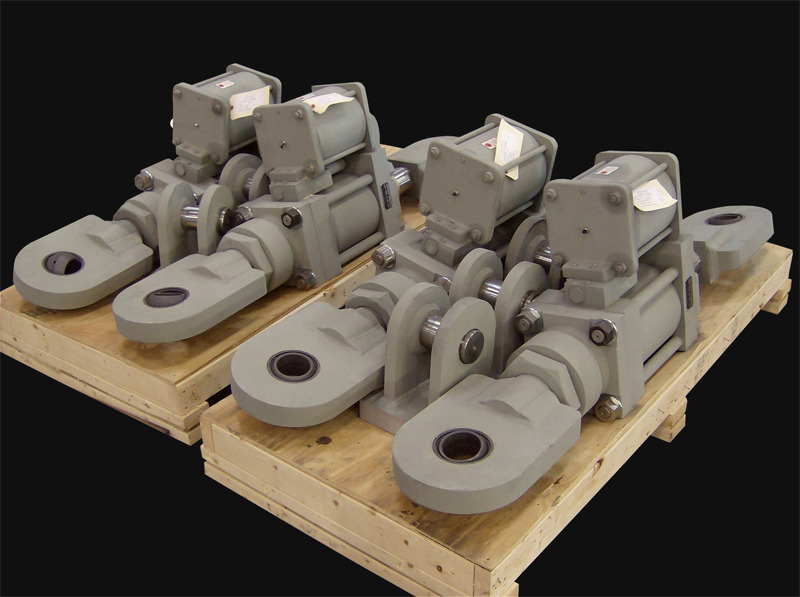

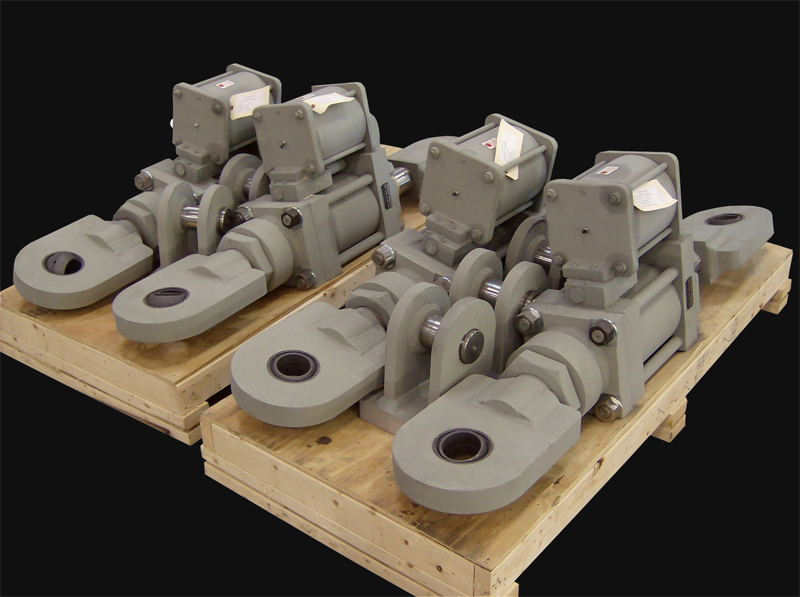

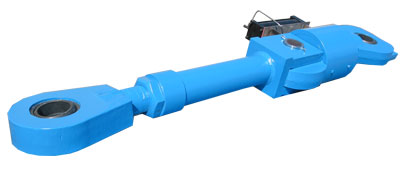

| Type: | Hydraulic Snubbers |

| Design: | 3,000-15,400 lb load/5″-12″ stroke |

| Material: | Carbon Steel |

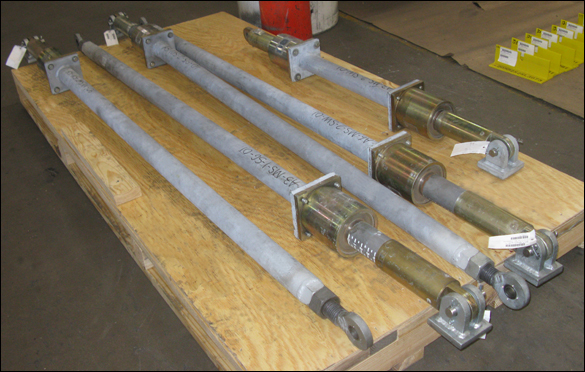

| Size: | 31″ up to 148″ pin-to-pin and cylinder diameters from 2.5″ to 5″ |

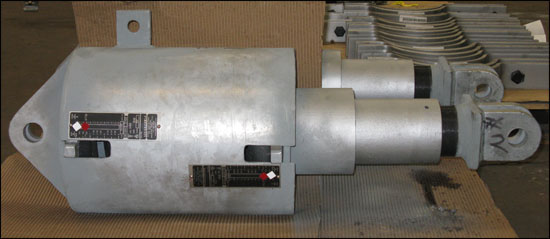

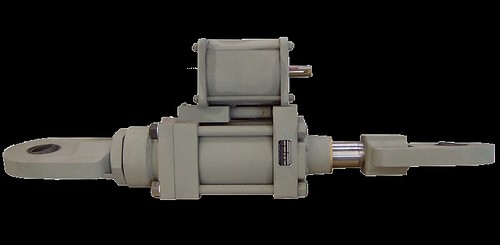

Piping Technology & Products designed these hydraulic snubbers for an ammonia plant in Louisiana. The snubbers ranged in length from 31" up to 148" pin-to-pin and cylinder diameters from 2.5" to 5". They are designed for an operating load ranging from 3,000 lb. to 15,400 lb. and have a 5" to 12" stroke. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to damage and possible failure of the piping system.

Most hydraulic snubbers have a piston which is relatively unconstrained in motion at low displacement rates. At high displacement rates the piston "locks up", that is, the force required to move the piston increases substantially, usually as a result of the closing of a valve.

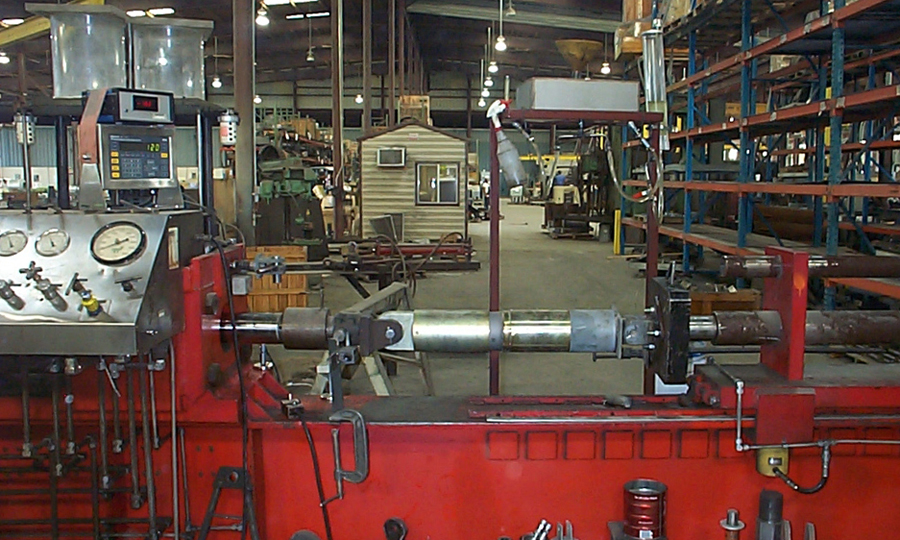

Hydraulic snubbers are used in many applications and are typically needed urgently in operational facilities. We have provided these products in all major verticals including refining, petrochemical, renewables, and power operations.. Our hydraulic snubbers are built in accordance with ASME Boiler and pressure vessel code and our Laconia, New Hampshire operations have ASME Nuclear Stamp "NS" for nuclear applications.

PT&P REF. ORIGINAL POST 11232016