Meet the presenters of PT&P’s Online Courses. Click on each video to learn about each course’s objectives, course outline, course module content, and grading breakdown.

Learn more here about PT&P’s online courses and register for a course

Meet the presenters of PT&P’s Online Courses. Click on each video to learn about each course’s objectives, course outline, course module content, and grading breakdown.

Learn more here about PT&P’s online courses and register for a course

The maximum shear stress theory states that failure of a piping component occurs when the maximum shear stress exceeds the shear stress at the yield point in a tensile test.

The Maximum Principle Stress Theory and Maximum Shear Stress Theory

This theory states that yielding in a piping component occurs when the magnitude of any of the three mutually perpendicular principal stresses exceeds the yield strength of the material.

Failure by general yielding, yielding at sub-elevated temperature, brittle fractures, and fatigue.

Stress analysis ensures the safety of piping and piping components, safety of connected equipment and supporting structure, and that piping deflections are within limits.

A term applied to calculations, which address the static and dynamic loading, resulting from the effects of gravity, temperature changes, internal pressures, fluid flow, seismic activity, and any external loads.

It is a visual representation of the effects of various loading conditions on a piping system between stress and strain.

Vibration, thermal bowing, creep, thermal fatigue, and steam/water.

Excessive flexibility causes an increase in material costs, pressure drops, and loss of pump efficiency.

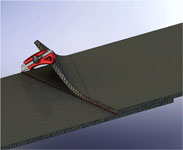

Using flexible piping with bends and turns, use of expansion loops between fixed locations, or use of expansion joints between two anchor points of a pipe run.

Flexibility analysis assures that there is not any overstress or fatigue, leakage at joints or distortions are piping connections or terminals.

To produce neither excessive stress within the configuration and limit excessive end reaction at the piping terminal.

Fluctuating temperatures, changes in pressure, and modification in flow rate.

July 25, 2013, Houston, TX – In an effort to expand our community presence and help students expand their education and interests, Piping Technology & Products is excited to announce our new partnership with the University of Houston’s College of Technology. As the goal of the UH College of Technology is to provide the highest quality education in fields such as mechanical engineering, construction management, and computer engineering, so is Piping Technology’s goal to help educate people interested in these fields as a public service to the community. As online courses become the norm for many colleges these days, PT&P realized this would be the perfect way to combine our thirty five years of manufacturing experience with the UH College of Technology’s established reputation.

This new online course is titled “Piping Design & Analysis Influence on Pipe Support Selection and Design”. The course covers the following topics: piping design and how it effects the overall configuration on preliminary piping design, initial layout, the total system, introduction to pipe stress analysis, detailed piping design, and how all of this influences pipe support and pipe hanger design. This is a self-paced course consisting of eight sections. The student will have four weeks to complete the eight sessions, which must be taken in sequential order.

This is an online course only, with no classroom meetings required.

This course is approved for 8 PDH hours for Texas Professional Engineers.

The College of Technology at the University of Houston was established over seventy years ago and offers numerous fully accredited undergraduate courses and masters’ degrees through three departments: Engineering Technology, Human Development and Consumer Sciences, Information and Logistics Technology.

Piping Technology & Products, Inc. is headquartered in Houston, TX and began business in 1978. PT&P and its wholly owned subsidiaries (U.S. Bellows, Inc., Sweco Fab, Inc., Pipe Shields, Inc., and Fronek Anchor/Darling Enterprises, Inc.) offer a wide range of engineered products and services for various industries and applications.

NOTE: this course is not available at the moment. We are revising it to include a part II on expansion joints.

Usually it would show a disparity between stresses at a particularpoint. For example, a carbon steel element joined to a stainless steel elementwould show significantly different stresses over the same temperature change.

Anchors will restrict movement in all directions and will also restrictthe rotation of the pipe as well. In the stress analysis, we may see loads inall three directions which will tell us how “strong” the anchordevice has to be.

Flexibility ensures that a piping system operates safely.