Piping Technology & Products, Inc., recently performed its snubber cycle test to prove the durability of a MSA 35 mechanical snubber manufactured for an engineering and construction company at Pine Bluff, Arkansas.

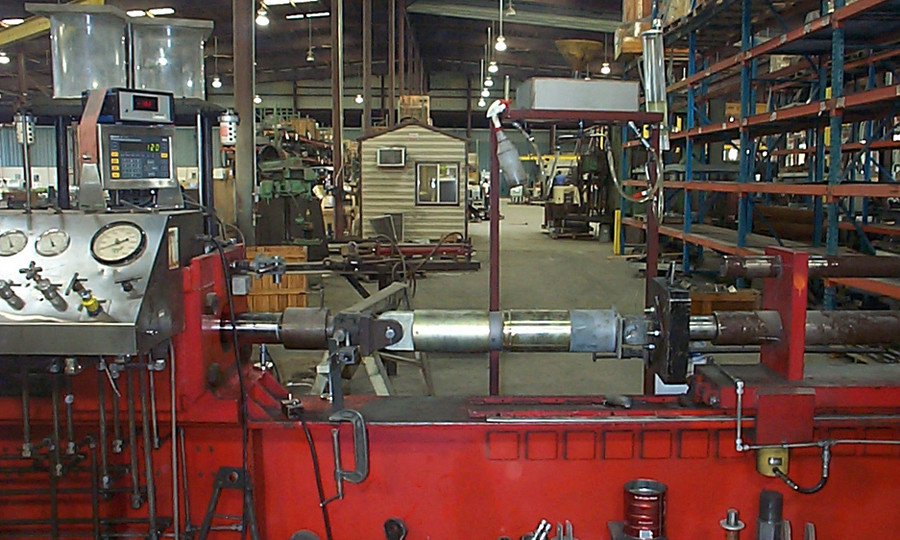

The cyclic test, performed using PT&P’s in-house, horizontal, hydraulic press, is designed to test snubbers at their two modes of operation. At high rates of loading, especially impact, the snubber is expected to provide very high resistance to movement. At low speeds snubbers are to provide very low resistance to movement. Testing a snubber at a low speed displays the normal wear and tear over an extended period of time.

In this case, a cyclic test was performed, in which the MSA 35 Mechanical Snubber with a load rating of 50,000 pounds and design travel of 6 inches was measured at a slow speed response. The low speed force remained at a fairly constant 500 pounds for the 50 hours and 5000 cycles it sustained. This value meets the common criteria that the drag force should be 2% or less than the rated load.

In addition to the snubber cycle drag test, Piping Technology & Products, Inc. has administered other tests such as the burst test for expansion joints. The tests executed by PT&P allow companies to attain the most precise and reliable data available to them. Using this to their advantage, customers will be able to compare data about the recently ordered products, to their individual standards of dependability and durability.

Piping Technology & Products, Inc. and its wholly owned subsidiaries are recognized leaders in manufacturing pipe hangers/pipe supports (variables, constants, cryogenic supports cold shoes, hot shoes, mechanical/hydraulic snubbers, slide bearing plates), expansion joints/compensators (metallic, fabric, rubber, slip-type) and ASME Code Fabrication. PT&P has engineering drawing production stress analysis and full in-house finite element analysis that are used to prove designs. The design software is developed in-house and the calculations contrived are further checked using hand calculations.