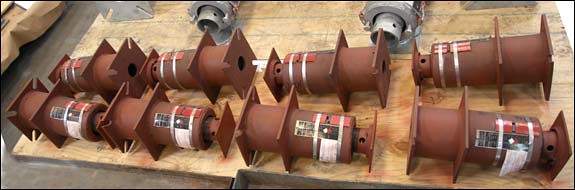

| Type: | F-Type Variable Spring Support Assemblies |

| Size: | Heights up to 12-3/4” Spring Casing Diameters from 6-5/8” to 8-5/8” Base plates from 9″x 9″ to 13-1/4” x 13-1/4″ |

| Design: | Operating Temp.: -49°F to 122°F Operating Loads from 697 lb. to 6093 lb. Movements of 0.04″ to 0.2” |

| Material: | Hot-dipped Galvanized Carbon Steel |

| Testing: | Load & Travel Test | Q.C. Inspection |

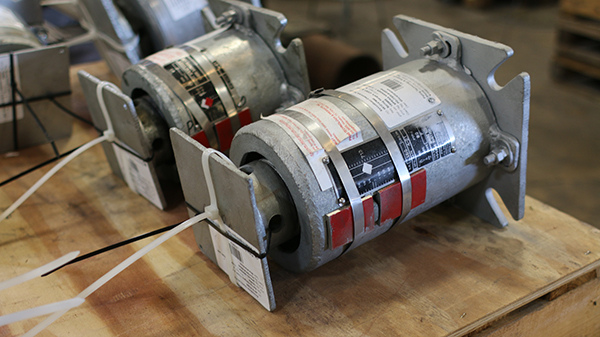

Piping Technology and Products, Inc. recently designed and manufactured F-Type variable spring supports with internal load columns for a petrochemical plant in Canada. The variables are fabricated from carbon steel that is able to accommodate low temperatures (A516-GR. 70N). The operating temperature ranges from -49°F to 122°F while supporting operating loads from 697 lb. to 6093 lb. and movements of 0.04″ to 0.2″. They are designed to accommodate installed heights up to 12-3/4″, with spring casing diameters from 6-5/8″ to 8-5/8″, along with base plates from 9″x 9″ to 13-1/4″ x 13-1/4″ for installing either by bolting or welding in the field. Load and travel tests, along with visual Q.C. inspections were performed before shipment.

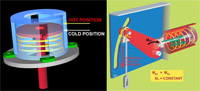

Variable supports are typically used for the following considerations in piping systems:

- Compensating for Thermal Expansion

- Maintaining Stress and Load

- Installation in Piping Systems

- Maintenance

- Supporting Heavy Loads

Variable spring cans play a crucial role in maintaining the integrity and stability of piping systems by compensating for thermal expansion or contraction, supporting heavy loads, and allowing for vertical movement. They are essential components in industries such as petrochemical, power generation, semiconductor, refining, paper and pulp processing, and other applications where large-scale piping systems are employed.

Variable spring cans come in a variety of designs and are constructed using different materials to suit specific applications and environmental conditions. Materials commonly used for variable spring cans include carbon steel, stainless steel, and special alloys. The selection of materials is crucial to ensure that the device can withstand the corrosive effects of certain fluids or harsh environmental conditions.

PT&P REF. ORIGINAL POST 05192020