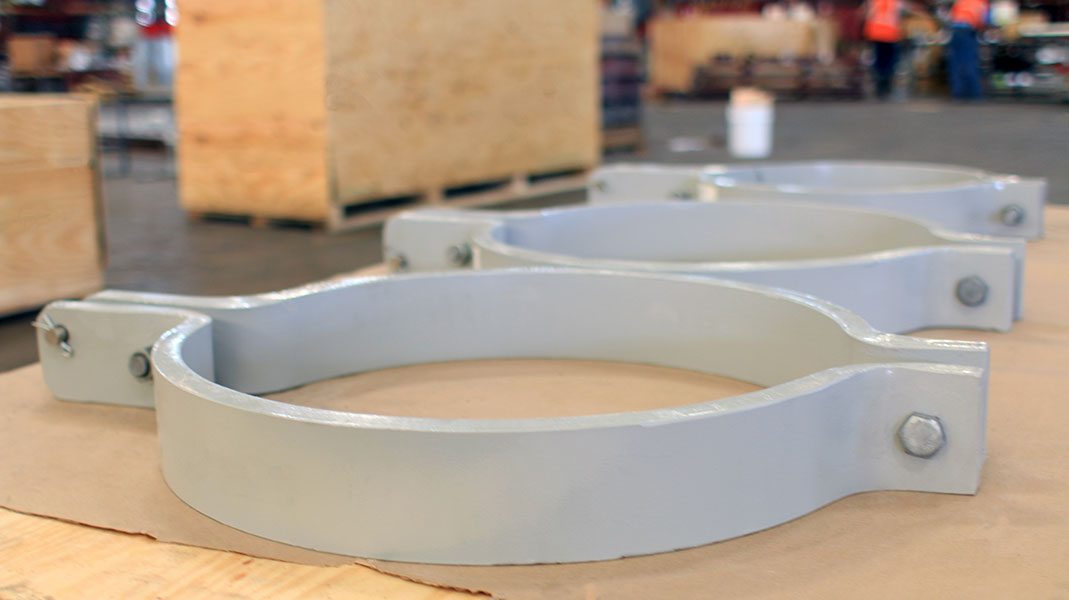

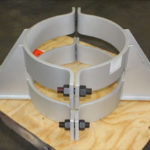

Pipe Clamps & Risers

A pipe clamp is a bolted pipe attachment which clamps around the pipe to connect the pipe to the remainder of a pipe hanger assembly. Piping Technology & Products, Inc. maintains an extensive inventory of pipe clamps required for pipe hanger and support assemblies. The pipe clamps and risers can be manufactured with galvanized or black finishes depending upon customer specifications.