Problem:

- PT&P received an RFI from a chemical plant with excessive vibration in the piping in the rack which resulted in breaking the shoe supporting the trunnion at the pipe elbow.

- They approached PT&P for their expertise in resolving vibration problems and for a recommendation of the appropriate pipe support for this solution.

- The plant experienced the vibration issue on the pipe for some time and wanted to resolve and eliminate the vibration permanently.

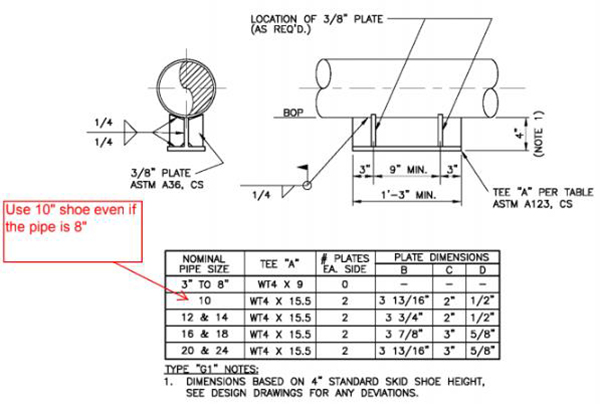

The engineer at the plant recommended using a Fig 11 skid shoe similar to the broken shoe in the picture with additional gussets.

There is a space limitation under the trunnion and can accommodate only a shoe type support.

Solution:

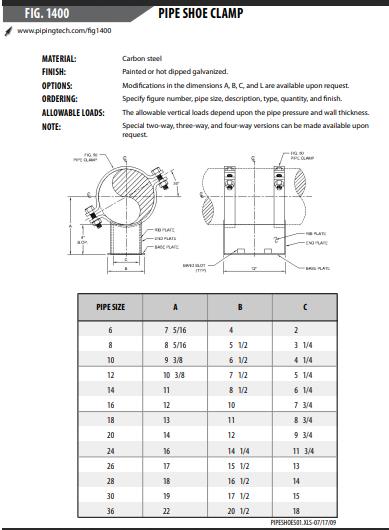

PT&P recommended using one of their most sturdy clamped shoe, special fabricated Fig 1400 pipe shoe lined with a lamination of Siltemp®-Fabreeka-Siltemp® or a lamination of Neoprene-Fabreeka-Neoprene depending on the temperature the trunnion is exposed to.

Another solution that most definitely works for eliminating the vibration problems in piping is using Hold Down clamps for pipe shoes lined with lamination of Siltemp®-Fabreeka-Siltemp® or a lamination of Neoprene-Fabreeka-Neoprene depending on the temperature the line is exposed to.

Siltemp® can withstand continuous temperature up to 1,800oF. Neoprene can be used for a temperature range of -50oF to 275oF. Fabreeka is good for a temperature range of -65oF to 200oF.

In this particular case, however, the Fig 1400 clamped shoe is a better option considering the gap between the trunnion and the structure on which the support would be resting.

Examples of PT&P supplied supports for Vibration Problems:

Example 1.

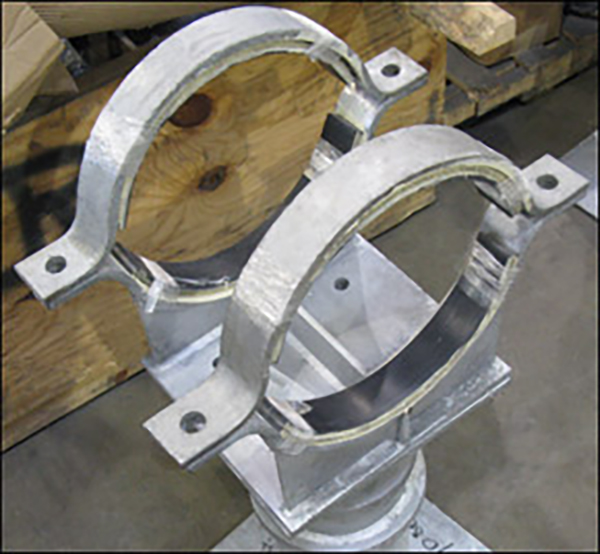

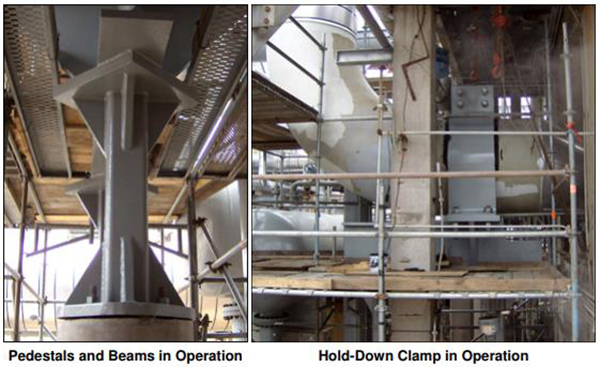

PT&P designed and manufactured custom elevated pipe shoe-clamp supports for part of a palletizer transfer line in a polymer plant. The custom supports were designed to prevent cracking in the welds and grout base due to severe vibration in the line. The assemblies have an overall height of 48″ with an adjustable load column. The clamp-shoes are 13″ wide by 14″ long and designed for a 12″ diameter aluminum pipe. The assemblies are carbon steel with a hot-dipped galvanize finish and include a unique laminated vibration dampening lining for the clamp.

Example 2.

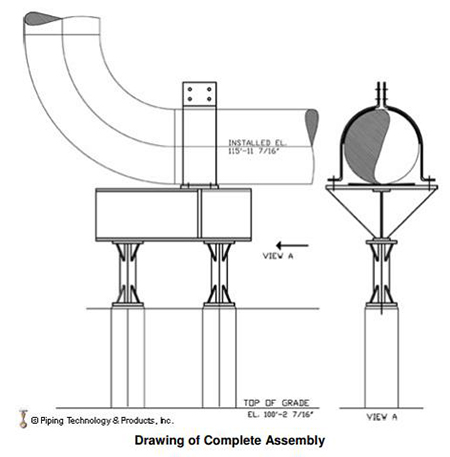

The 54” suction line carrying gas to the turbine at a rate of 1.7 million lb./hr developed a severe vibration in the line. The deflections in the line were up to ¾” and it was fully observable during operation.

PT&P designed and manufactured a special elevated hold down clamp, including a unique laminated vibration dampening lining. The entire assembly stands 22’ high and is coated with a carboline zinc finish.

After installation and resumption of operations, the vibrations are now almost imperceptible.

Summary:

Most of the time vibration in the line is for multiple reasons and not really associated with the stresses in piping. It might be because of some misalignment or due to the flow dynamics of the line content. However, in a majority of the cases, the vibrations can be alleviated by using adequate hold-downs or by use of proper supports. The surest first step is to assess the line routings and configurations, and determine the types of supports and that they are all located appropriately.

For vibrations associated to pump cavitation or believed to be originating from equipment, a detailed vibration analysis will be a better option to go with. PT&P has the expertise to perform a basic vibration analysis during a dynamic stress analysis using CAESAR software. Many of the times it is initially found to be most likely attributable to flow conditions. Of these, some require extensive flow analyses undertaken by a qualified process engineer; often a costly process.

However, we are also aware that many vibration problems can be resolved by the application of good engineering practices and empirical engineering methods. These together with augmentation of an existing design can resolve the problems at a more moderate cost.

PT&P has performed several remediations of piping manifesting severe vibrations and associated line displacements. All of the remedial actions recommended, and taken, so far have been successful. All the solutions were derived through empirical methods, and custom-designed clamps were utilized with special vibration dampening linings. For those scenarios, no vibration analyses were performed, nor deemed necessary to arrive at completely satisfactory solutions. PT&P has had considerable success with these approaches.