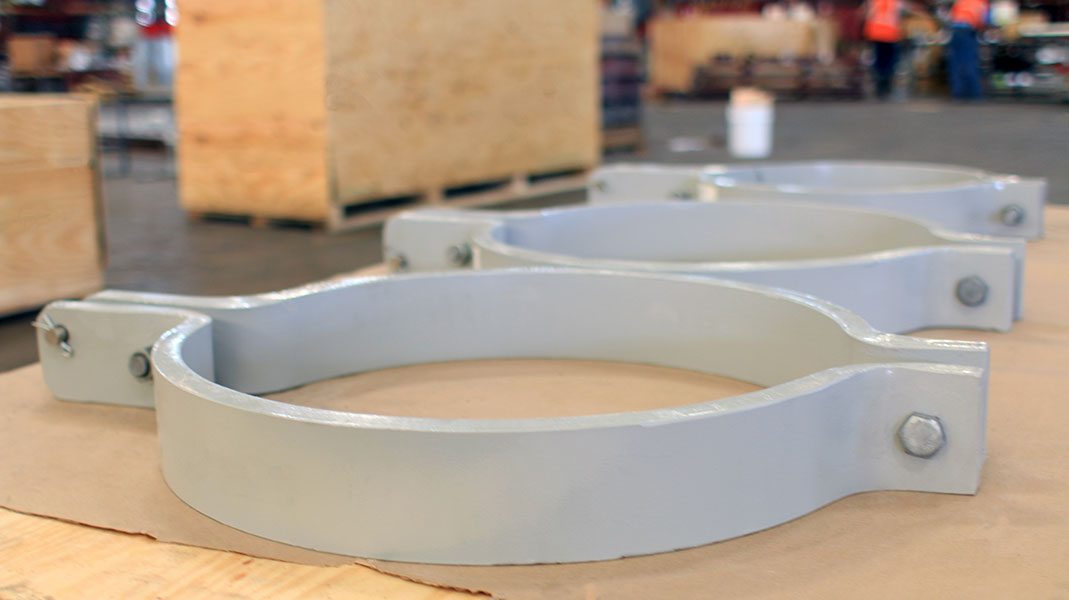

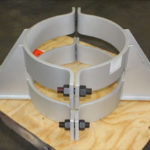

TYPES & SIZES

Technical Information

Methods of Protecting against Corrosion

Considering All Movement in Pipe Support Design

Comparative Corrosion Resistance Guide

Finite Element Analysis on a Pipe Clamp

Exploring Plate Thickness of a Pipe Clamp

Support Assembly Components

Request a Quote