Field Survey & Inspection

Call our field service team now: +1 (713) 992-7048

Or contact field services by submitting this form

Scope of Services

Field Services Photo Gallery

Site Survey

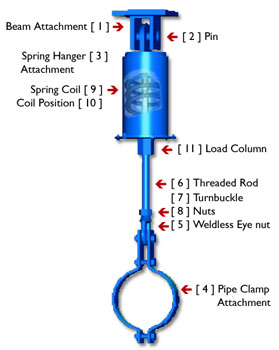

For the site survey we will audit your supports on any of the lines that you point out to us and verify their condition. We will examine the spring supports — we will check the housings, coils, and all related hardware. We will mark each support as OK, Replace, or Adjust – in the case of variable and constant spring supports. Upon completion of the survey we will provide a report listing all of the supports and our recommendations. We will also provide you with a quotation for the supports that we recommend that you replace.

Stress Analysis and Design

We can provide pipe stress analysis and pipe support design as well using current modeling software.

Pipe Support Testing

We can come onto site and test your constant supports and variable supports.

Production

PT&P is a complete and fully qualified manufacturer of pipe supports and hangers. We have over 25 years of experience and are certain that we can meet any deadline that you need for the supports. Our quotation will include material and manufacturing costs, as well as the time frame for the supply of the recommended supports.

Installation

PT&P has over 10 years of experience in the installation of pipe supports and over 35 years of manufacturing experience. Our crews work safely and can install any of our supports. We have welders, technicians, engineers, and supervisors.

Oversight

PT&P will provide qualified site management personnel to oversee the installation of the supports. The individual(s) will provide technical assistance to the contractor, as well as Client personnel.

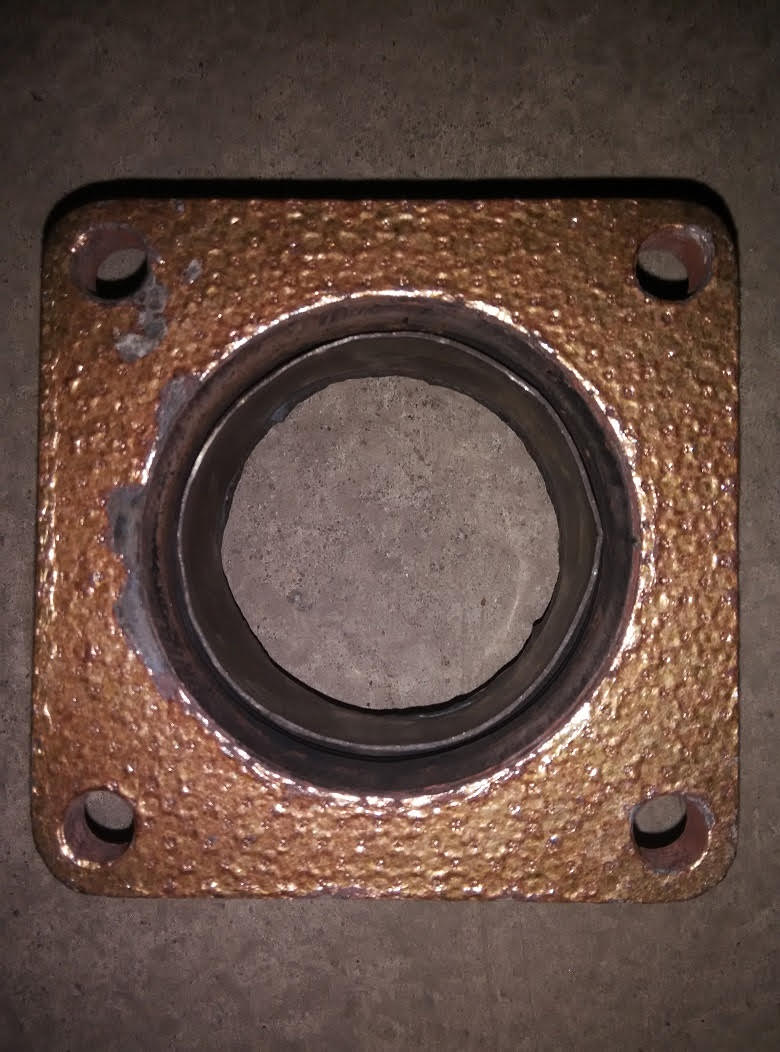

Examples of Corroded Springs |

|

|

|

|

|

24/7 Emergency Services: |

Piping Technology is available to help with any emergency service requests, 24 hours a day, 7 days a week. Piping Technology is available to help with any emergency service requests, 24 hours a day, 7 days a week.

With a large inventory of stock components for pipe supports and expansion joints and a shop that runs 3 shifts around the clock, PT&P can quickly assemble and ship products for any situation. E-mail us at emergency@pipingtech.com or fill out our emergency service form. We’ll immediately be notified and a representative will call you back within 30 minutes to assist you. A response is guaranteed in the evenings and on weekends and holidays. |

Case studies: PT&P Emergency Service 24×7 Hotline |

|||||||||||||||||||

Case Study #1 |

|||||||||||||||||||

| An Alaskan petroleum firm called upon the PT&P Field Service Team on a Friday evening to aid them in an immediate replacement of a defective 48″ dia. expansion joint. The expansion joint was damaged during the plant startup when a G417 pump suddenly failed. A replacement expansion joint was designed, manufactured, and shipped the next day. It was installed at the customer’s location within 2 days of receiving the call. | |||||||||||||||||||

|

|||||||||||||||||||

Case Study #2 |

|||||||||||||||||||

|

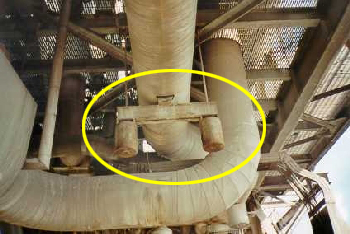

On a Friday evening, PT&P’s Field Service Team received an emergency call from a company located in Jamaica. They requested for PT&P to inspect failing pipe supports near their steam turbine.

A PT&P field service representative arrived the next day to survey and inspect the system. PT&P supplied and delivered two variable spring assemblies to Jamaica on the following Monday. |

||||||||||||||||||

|

Rusted G-can found on-site during inspection |

|||||||||||||||||||

|

|||||||||||||||||||

Past Field Service Experience:

Piping Technology has been in business for over 35 years. We have provided pipe supports for many major construction projects throughout the world. Our Field Service Division has participated in site surveys, support inspection, support installation and expansion joint inspection and installation..

We have worked in the following countries:

| Trinidad and Tobago: | Bechtel, Wood Group, Atlantic LNG |

| U.S. Virgin Islands: | Limetree Bay Energy |

| Kuwait: | Kuwait Power, Equate |

| Canada: | PetroCanada, Agrium, Hitachi Power, Alstom, Canaport LNG, Thorold Power, Inter Pipeline (Heartland PetroChemical Complex) |

| Dubai: | Dubai Natural Gas |

| Italy: | Alstom Engineering |

| Malaysia: | Petronas |

| Mexico: | Intergen, Vallaodolid, Condisa, Pemex, Energia Campeche |

| Singapore: | Sembcorp, Exxon, Singapore Refining Company |

| United Kingdom: | Murco |

| United States: | Lyondell Houston Refinery, Shell Deer Park, Bechtel Sabine Pass, Aker Kvaerner Cameron LNG, Lyondell Equistar, Pasadena Refining, Calpine Corporation, Chevron Phillips, Huntsman Chemical, Dow, BP, Rhodia, Entergy, Exxon, Valero Refining, Conoco Phillips, Entergy, Black & Veatch West County, Alstom Power, Citgo, Duke Energy, Marathon, Shaw Cleco, Technip, Constellation Energy, Flint Hills Resources, Westlake Chemical, So Cal Edison, TC Energy, Luminant Power, Covestro, Panda Power, Holly Frontier, Aries Clean Energy, DynoNobel, Orion, Ascend Performance Materials, Oglethorpe Power, ODEC (Old Dominion Electric Cooperative) |

All of our technicians, engineers and other site personnel are familiar with all of our product line and are qualified to work on pipe supports, variable assemblies, constant effort supports, expansion joints and snubbers that we manufacture or our competitors. Please contact us if you have questions, and we will be able happy to assist you.

Installation & Maintenance Guidance:

- quick lock out of variable and constant springs during shutdowns

- retrofit supports to replace existing damaged supports

- refurbish, repair, or replace damaged pipe supports, expansion joints, or hardware components

- installation of field designed small bore supports

| With an expertise in the installation and maintenance of various pipe support and expansion joint systems, PT&P’s Field Service Team is readily available to provide the following services: | ||||||

|

||||||

|

||||||

For more comprehensive assistance, PT&P’s Field Service Team is trained to perform installation and repair on-site:

|

||||||

|

More Details on Field Survey & Inspection: Due to unanticipated changes in the operating conditions of a piping system, periodic inspection and regular maintenance is necessary to prevent unforeseen shut-downs and to optimize production. During each inspection process, PT&P’s Field Service Team can:

- thoroughly inspect the pipe support/expansion joint system

- perform design audits

- record digital images of existing problems

- provide a detailed written assessment for preliminary findings and recommendations

- perform stress analyses to verify design

- assist in drawing regeneration or updates

Quality Assurance

Piping Technology & Products, Inc. follows stringent standards to ensure quality products and services for its customers. PT&P is in compliance with the following codes and standards as applicable:

|

|

|

|

|

|||