Download PDF

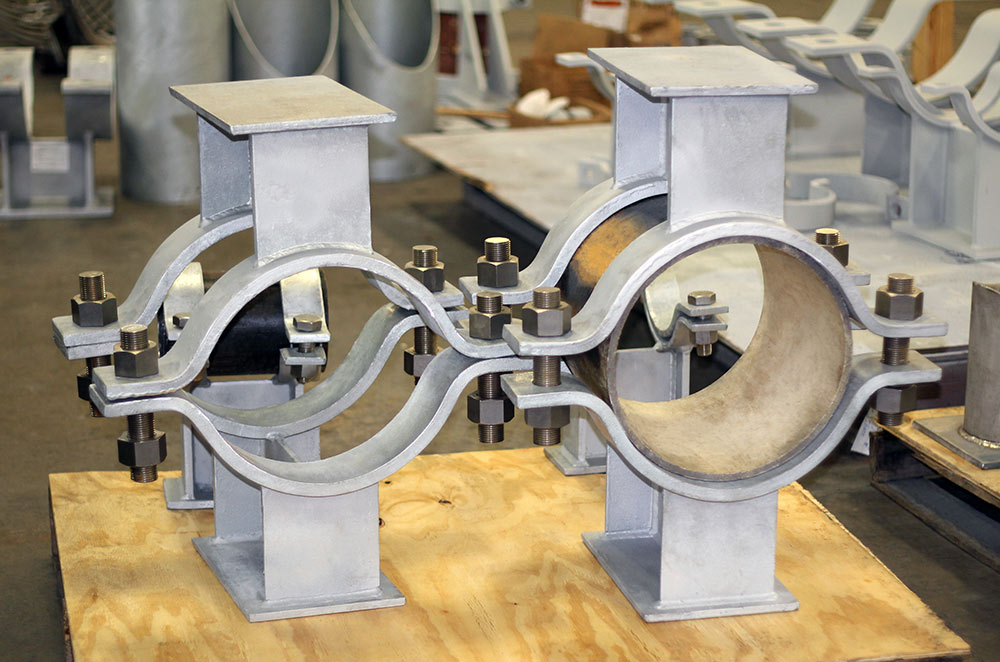

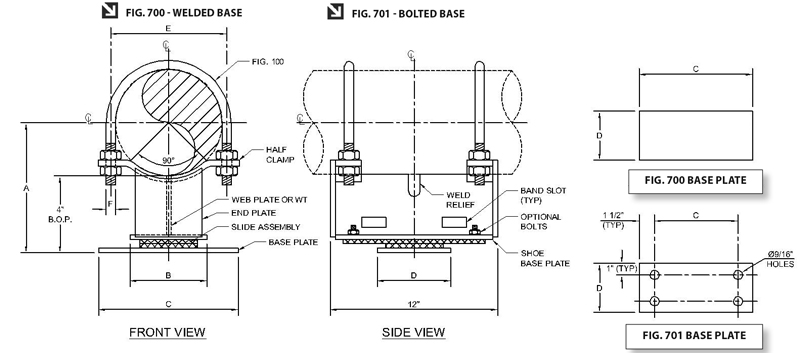

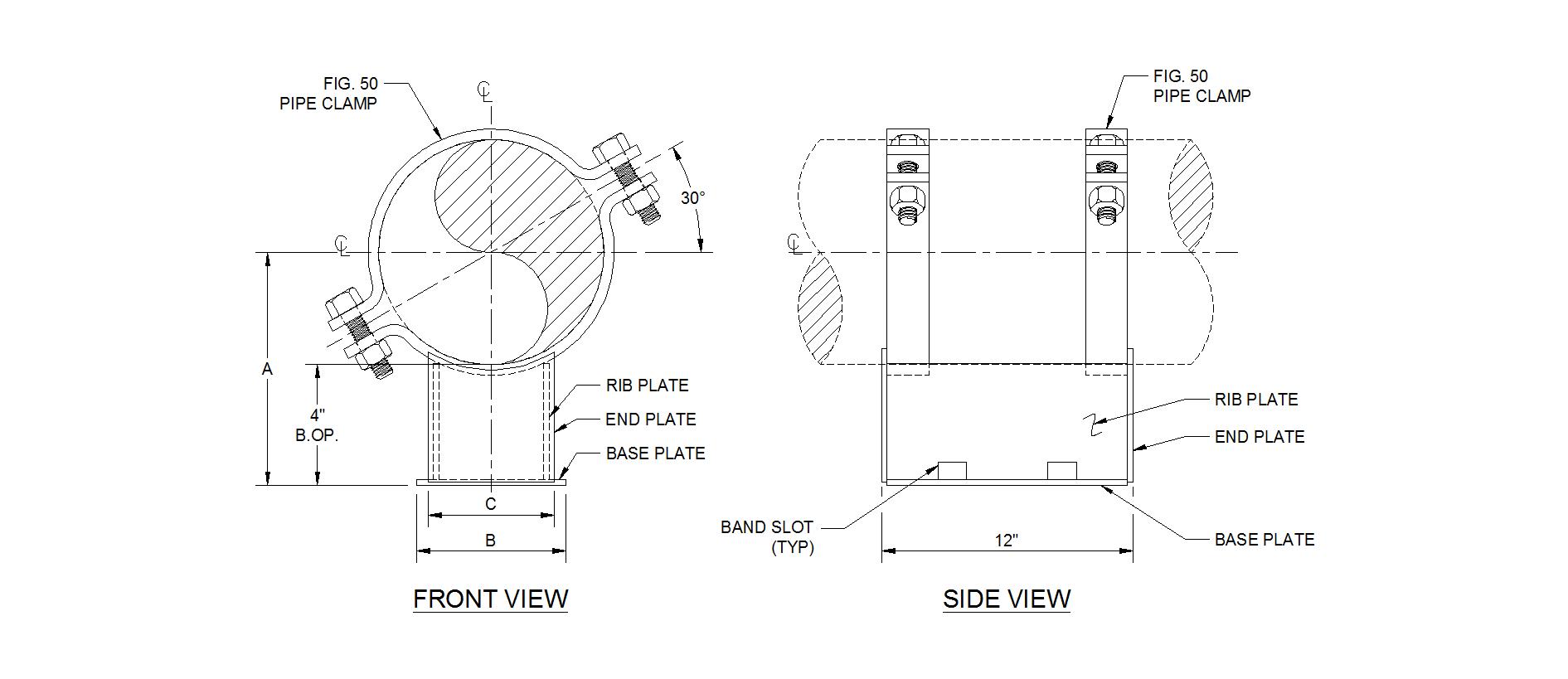

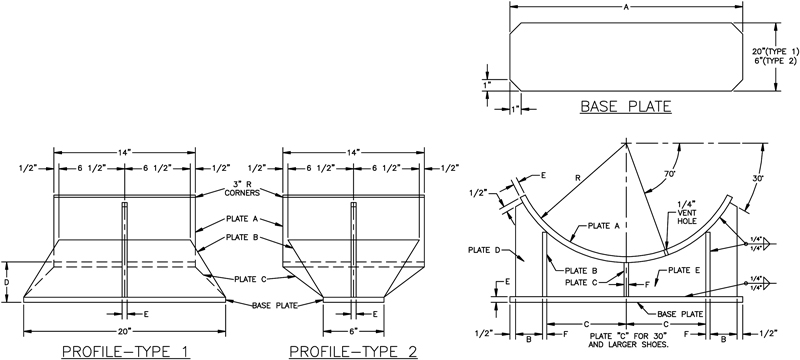

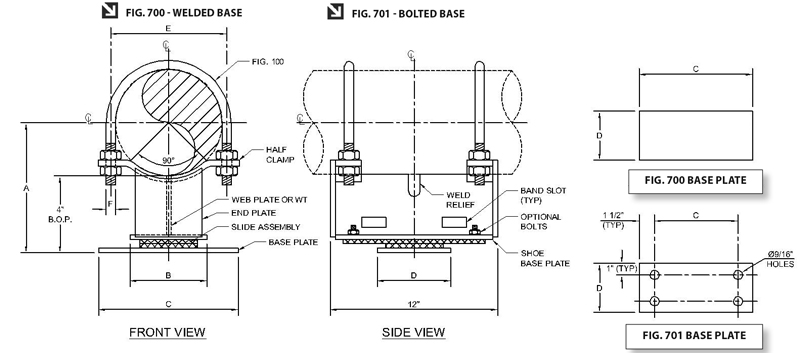

Fig. 700: U-Bolt Cradle Support with Bonded/Bolted Slide Plate

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE:

• Optional bolted base plate, specify Fig. 701

• End Plates provided for pipe sizes 3″ & above

• For upper graphite slide material to be of bolted design, specify Fig. 700 base plate or Fig. 701 base plate (see below).

| PIPE SIZE | A | B | C | D | E | F | APPROX. WEIGHT (lb. per each) |

| 2 | 5 3/16 | 4 | 12 | 5 | 2 7/8 | 3/8 | 14.0 |

| 3 | 5 3/4 | 4 | 12 | 5 | 4 1/8 | 1/2 | 14.0 |

| 4 | 6 1/4 | 4 | 12 | 5 | 5 1/8 | 1/2 | 15.0 |

| 6 | 7 5/16 | 4 | 12 | 5 | 7 3/8 | 5/8 | 22.0 |

| 8 | 8 5/16 | 4 | 12 | 5 | 9 3/8 | 5/8 | 25.0 |

| 10 | 9 3/8 | 4 | 12 | 5 | 11 5/8 | 3/4 | 31.0 |

| 12 | 10 3/8 | 4 | 12 | 5 | 13 3/4 | 7/8 | 39.0 |

| 14 | 11 | 4 | 12 | 5 | 15 | 7/8 | 46.0 |

| 16 | 12 | 4 | 12 | 5 | 17 | 7/8 | 49.0 |

| 18 | 13 | 7 | 15 | 5 1/2 | 19 1/8 | 1 | 66.0 |

| 20 | 14 | 7 | 15 | 5 1/2 | 21 1/8 | 1 | 70.0 |

| 24 | 16 | 7 | 15 | 5 1/2 | 25 1/8 | 1 | 78.0 |

Download PDF

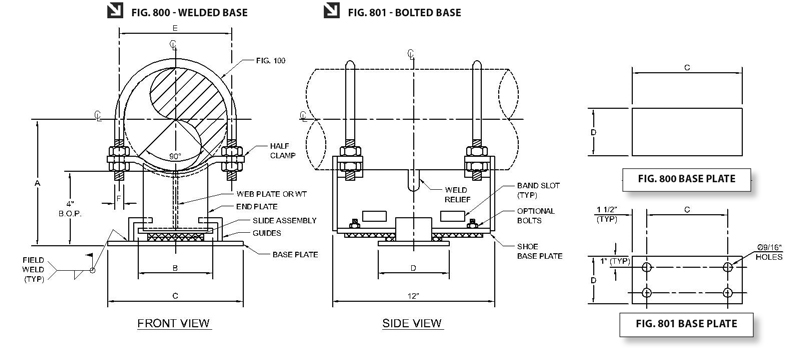

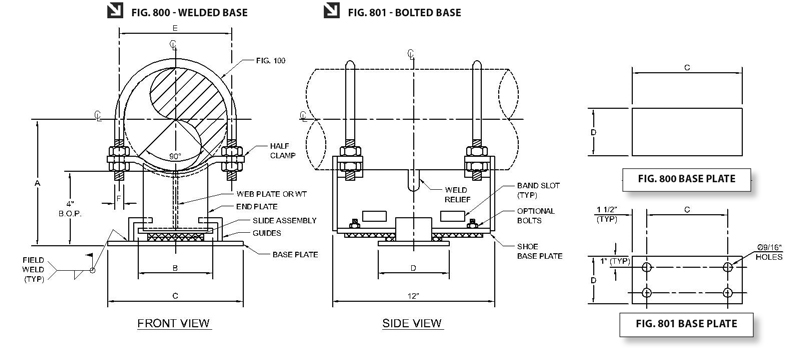

Fig. 800: U-Bolt Cradle Support with Guide & Slide Plate

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE:

• Optional bolted base plate, specify Fig. 801.

• For upper graphite slide material to be of bolted design, specify Fig. 800 base plate or Fig. 801 base plate (see below).

| PIPE SIZE | A | B | C | D | E | F | APPROX. WEIGHT (lb. per each) |

| 2 | 5 3/16 | 4 | 7 1/4 | 5 | 2 7/8 | 3/8 | 17.0 |

| 3 | 5 3/4 | 4 | 7 1/4 | 5 | 4/1/8 | 1/2 | 19.0 |

| 4 | 6 1/4 | 4 | 7 1/4 | 5 | 5/18 | 1/2 | 21.0 |

| 6 | 7 5/16 | 4 | 7 1/4 | 5 | 7 3/8 | 5/8 | 24.0 |

| 8 | 8 5/16 | 4 | 7 1/4 | 5 | 9 3/8 | 5/8 | 26.0 |

| 10 | 9 3/8 | 4 | 7 1/4 | 5 | 11 5/8 | 3/4 | 33.0 |

| 12 | 10 3/8 | 4 | 7 1/4 | 5 1/2 | 13 3/4 | 7/8 | 41.0 |

| 14 | 11 | 4 | 7 1/4 | 5 1/2 | 15 | 7/8 | 48.0 |

| 16 | 12 | 4 | 7 1/4 | 5 1/2 | 17 | 7/8 | 51.0 |

| 18 | 13 | 7 | 10 3/4 | 5 1/2 | 19 1/8 | 1 | 72.0 |

| 20 | 14 | 7 | 10 3/4 | 5 1/2 | 21 1/8 | 1 | 76.0 |

| 24 | 16 | 7 | 11 1/4 | 5 1/2 | 25 1/8 | 1 | 86.0 |

Download PDF

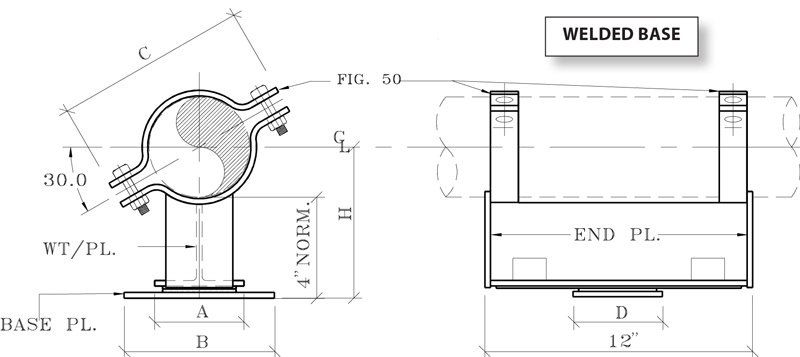

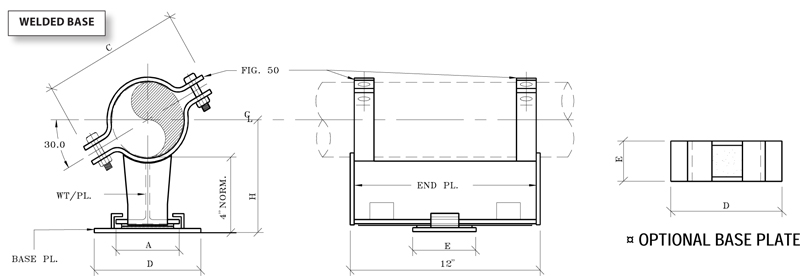

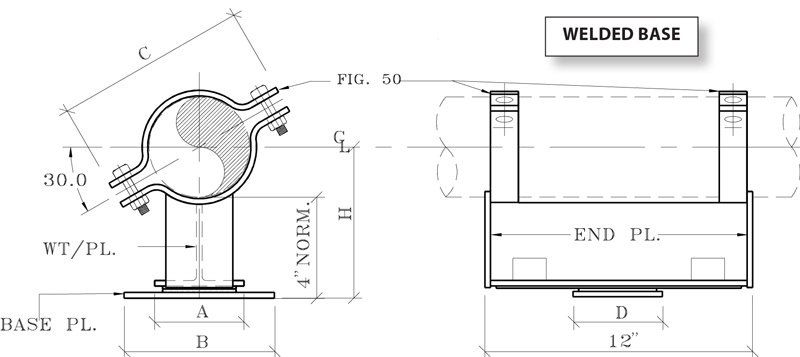

Fig. 900: Bolt Cradle Support with Bonded/Bolted Slide Plate (Welded Base)

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE: End Plates provided for pipe sizes 3″ & above

| PIPE SIZE | A | B | C | D | H |

| 2 | 4 | 12 | 5 1/2 | 5 | 5 3/16 |

| 2 1/2 | 4 | 12 | 6 3/8 | 5 | 5 7/16 |

| 3 | 4 | 12 | 7 | 5 | 5 3/4 |

| 4 | 4 | 12 | 8 9/16 | 5 | 6 1/4 |

| 5 | 4 | 12 | 9 11/16 | 5 | 6 13/16 |

| 6 | 4 | 12 | 11 5/8 | 5 | 7 5/16 |

| 8 | 4 | 12 | 13 7/8 | 5 | 8 5/16 |

| 10 | 4 | 12 | 17 | 5 | 9 3/8 |

| 12 | 4 | 12 | 18 15/16 | 5 | 10 3/8 |

| 14 | 4 | 12 | 21 | 5 | 11 |

| 16 | 4 | 12 | 23 | 5 | 12 |

| 18 | 7 | 15 | 25 7/8 | 5 1/2 | 13 |

| 20 | 7 | 15 | 28 | 5 1/2 | 14 |

| 24 | 7 | 15 | 33 1/2 | 5 1/2 | 16 |

Download PDF

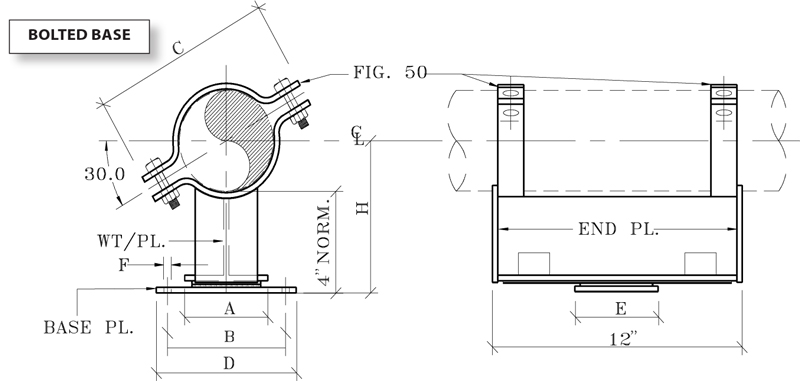

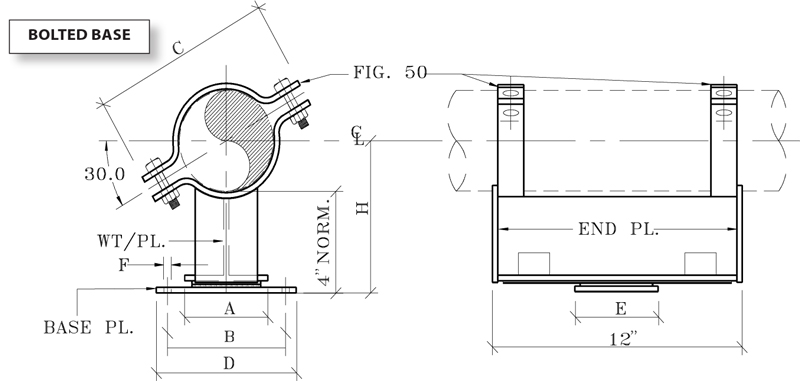

Fig. 1000: Bolt Cradle Support with Bonded/Bolted Slide Plate (Bolted Base)

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE: End Plates provided for pipe sizes 3″ & above

| PIPE SIZE | A | B | C | D | E | F | H |

| 2 | 4 | 16 | 5 1/2 | 18 | 5 | 13/16 | 5 3/16 |

| 2 1/2 | 4 | 16 | 6 3/8 | 18 | 5 | 13/16 | 5 7/16 |

| 3 | 4 | 16 | 7 | 18 | 5 | 13/16 | 5 3/4 |

| 4 | 4 | 16 | 8 9/16 | 18 | 5 | 13/16 | 6 1/4 |

| 5 | 4 | 16 | 9 11/16 | 18 | 5 | 13/16 | 6 13/16 |

| 6 | 4 | 16 | 11 5/8 | 18 | 5 | 13/16 | 7 5/16 |

| 8 | 4 | 16 | 13 7/8 | 18 | 5 | 13/16 | 8 5/16 |

| 10 | 4 | 16 | 17 | 18 | 5 | 13/16 | 9 3/8 |

| 12 | 4 | 16 | 18 15/16 | 18 | 5 | 13/16 | 10 3/8 |

| 14 | 4 | 16 | 21 | 18 | 5 | 13/16 | 11 |

| 16 | 4 | 16 | 23 | 18 | 5 | 13/16 | 12 |

| 18 | 7 | 18 1/2 | 25 7/8 | 21 | 5 1/2 | 15/16 | 13 |

| 20 | 7 | 18 1/2 | 28 | 21 | 5 1/2 | 15/16 | 14 |

| 24 | 7 | 18 1/2 | 33 1/2 | 21 | 5 1/2 | 15/16 | 16 |

Download PDF

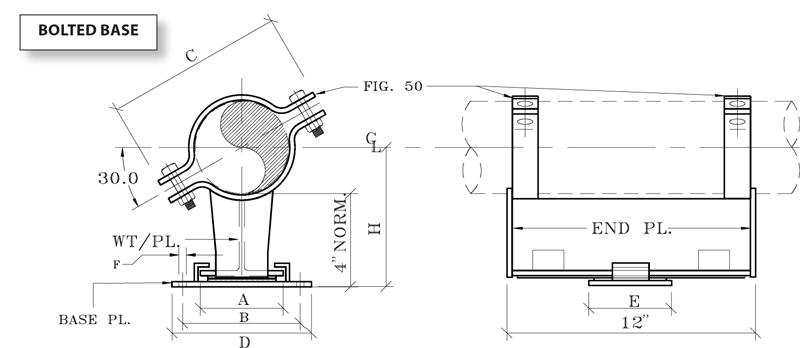

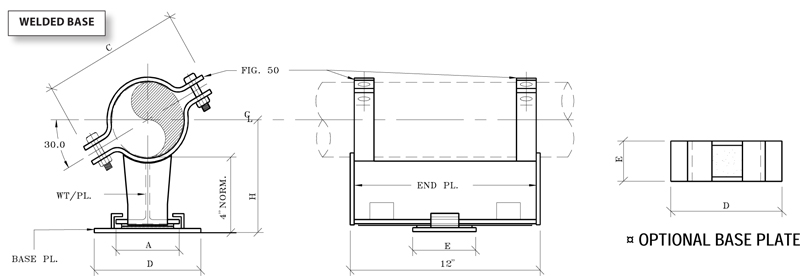

Fig. 1100: Bolt Cradle Support with Guide & Slide Plate (Welded Base)

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, C, D, E, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500 °F specify bolted construction.

PIPE SIZE

| A

| C

| D

| E

| H

|

2

| 4

| 5 1/2

| 7 1/4

| 5

| 5 3/16

|

2 1/2

| 4

| 6 3/8

| 7 1/4

| 5

| 5 7/16

|

3

| 4

| 7

| 7 1/4

| 5

| 5 3/4

|

4

| 4

| 8 9/16

| 7 1/4

| 5

| 6 1/4

|

5

| 4

| 9 11/16

| 7 1/4

| 5

| 6 13/16

|

6

| 4

| 11 5/8

| 7 1/4

| 5

| 7 5/16

|

8

| 4

| 13 7/8

| 7 1/4

| 5

| 8 5/16

|

10

| 4

| 17

| 7 1/4

| 5

| 9 3/8

|

12

| 4

| 18 15/16

| 7 1/4

| 5

| 10 3/8

|

14

| 4

| 21

| 7 1/4

| 5

| 11

|

16

| 4

| 23

| 7 1/4

| 5

| 12

|

18

| 7

| 25 7/8

| 10 3/4

| 5 1/2

| 13

|

20

| 7

| 28

| 10 3/4

| 5 1/2

| 14

|

24

| 7

| 33 1/2

| 11 1/4

| 5 1/2

| 16

|

Download PDF

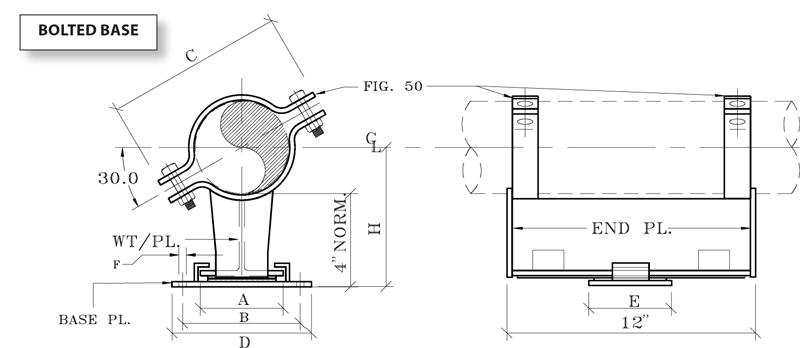

Fig. 1200: Bolt Cradle Support with Guide & Slide Plate (Bolted Base)

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

| PIPE SIZE | A | B | C | D | E | F | H |

| 2 | 4 | 9 1/4 | 5 1/2 | 11 1/4 | 5 | 13/16 | 5 3/16 |

| 2 1/2 | 4 | 9 1/4 | 6 3/8 | 11 1/4 | 5 | 13/16 | 5 7/16 |

| 3 | 4 | 9 1/4 | 7 | 11 1/4 | 5 | 13/16 | 5 3/4 |

| 4 | 4 | 9 1/4 | 8 9/16 | 11 1/4 | 5 | 13/16 | 6 1/4 |

| 5 | 4 | 9 1/4 | 9 11/16 | 11 1/4 | 5 | 13/16 | 6 13/16 |

| 6 | 4 | 9 1/4 | 11 5/8 | 11 1/4 | 5 | 13/16 | 7 5/16 |

| 8 | 4 | 9 1/4 | 13 7/8 | 11 1/4 | 5 | 13/16 | 8 5/16 |

| 10 | 4 | 9 1/4 | 17 | 11 1/4 | 5 | 13/16 | 9 3/8 |

| 12 | 4 | 9 1/4 | 18 15/16 | 11 1/4 | 5 | 13/16 | 10 3/8 |

| 14 | 4 | 9 1/4 | 21 | 11 1/4 | 5 | 13/16 | 11 |

| 16 | 4 | 9 1/4 | 23 | 11 1/4 | 5 | 13/16 | 12 |

| 18 | 7 | 13 3/4 | 25 7/8 | 16 1/4 | 5 1/2 | 15/16 | 13 |

| 20 | 7 | 13 3/4 | 28 | 16 1/4 | 5 1/2 | 15/16 | 14 |

| 24 | 7 | 14 1/4 | 33 1/2 | 16 1/4 | 5 1/2 | 15/16 | 16 |