One of the pragmatic issues PT&P sees often in the field are issues around the alignment of piping. As the diameter of piping increases, construction teams have an increased difficulty in getting a complete alignment which can pose issues for highly sensitive equipment such as compressors.

Key sources of misalignment issues are:

- Settling of Heavy Equipment – PT&P has spoken to numerous operators who have soil conditions that lead to Equipment shifting or sinking over time.

- Construction “Tolerance” – it is very difficult with larger diameter piping to get perfect alignment in construction.

- Damage to Piping – any damage which occurs over time leading to even modest deformation of the piping will cause potential alignment issues.

The issue with Piping Misalignment is that it puts strain at flange connections which would cause maintenance issues with expensive equipment.

|

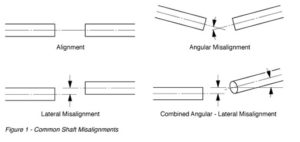

The key to solving Piping Alignment issues is properly identifying the problem. This should include both the types of misalignment AND the expected change over time. For example, an issue such as settling will likely grow over time so a fixed solution will not be as effective as one which allows for adjustment.

PT&P product solutions for Alignment include:

In PT&P’s experience, the use of expansion joints for alignment around equipment such as Pumps and Compressors is very common. As the diameter of the piping gets larger, it becomes increasingly difficult to achieve the level of alignment demanded by equipment manufacturers. PT&P is uniquely qualified to build expansion joints for alignment solutions as we are the only major Expansion Joint manufacturer that also builds Pipe Spools and Engineered Pipe Supports. As a result, our solution can utilize multiple tools to solve alignment issues.

The difference in using an Expansion Joint for alignment rather than thermal growth is that the force required to compress or extend the bellows must be applied manually. The Expansion Joint can be pre-set and locked into place at PT&P or put into place in the field. With some Expansion Joints, the spring rate of the Expansion Joint may be too great to place on the Piping System. In these scenarios, the Expansion Joint should be pre-set for the required movement and locked into place so the force of the Bellows Spring rate is not applied to the Piping system. Examples of Expansion Joints that can be used for alignment include:

- Externally Pressurized Expansion Joint – in this EJ, the media flows outside the expansion joint. This eliminates pressure inside the EJ and issues around squirm pressure allowing for high degrees of Axial movement. Because the exterior of this EJ is a pipe, it also handles difficult exterior conditions and rough handling better. View past projects in our product archives for externally pressurized expansion joints.

- Universal Expansion Joints – these expansion joints are useful for supporting larger degrees of lateral misalignment. View past projects in our product archives for universal expansion joints.

- Single Expansion Joint – these expansion joints can be used for any type of misalignment but offer more limited amounts of adjustment. View past projects in our product archives for single expansion joints.

Custom Pipe Spool

PT&P can fabricate a custom Pipe Spool designed to resolve the alignment issue or integrate a pipe spool piece with an expansion joint. For example, a spool piece could be used to solve an angular misalignment issue while an expansion joint could be used to solve a lateral alignment issue. PT&P can make Pipe Spools out of any material required including:

- Stainless – 304, 316, 321, …

- Hastelloy

- Inconel

- INCOLOY®

PT&P service offering for Piping Alignment and Pipe Strain Solutions include:

Product Selection Support– when you order products from PT&P, we include support on product selection as a part of the order. You can reach an expert from PT&P who can assist in providing a recommended on the type of expansion joints that best suit a designed range of adjustability.

Laser Scanning – for existing alignment issues, PT&P can use an as-built laser scan to understand the existing level of misalignment and develop a solution. Laser scanning is particularly useful for designing custom Pipe Spools.

Custom Pipe Spool / Expansion Joint Design – PT&P can custom design a solution to solve a specific alignment issue using different types of tools that best fit the scenario. We can also advise of material options in the cases of difficult conditions in terms of media.

Pipe Strain Measurement – PT&P can measure strain at flange connections to better understand the strain being placed on sensitive equipment.