Types & Sizes

Technical Information

Installation & Maintenance

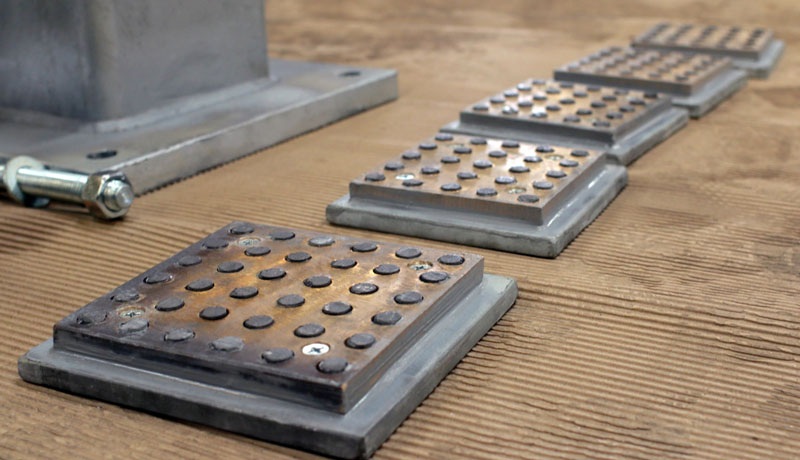

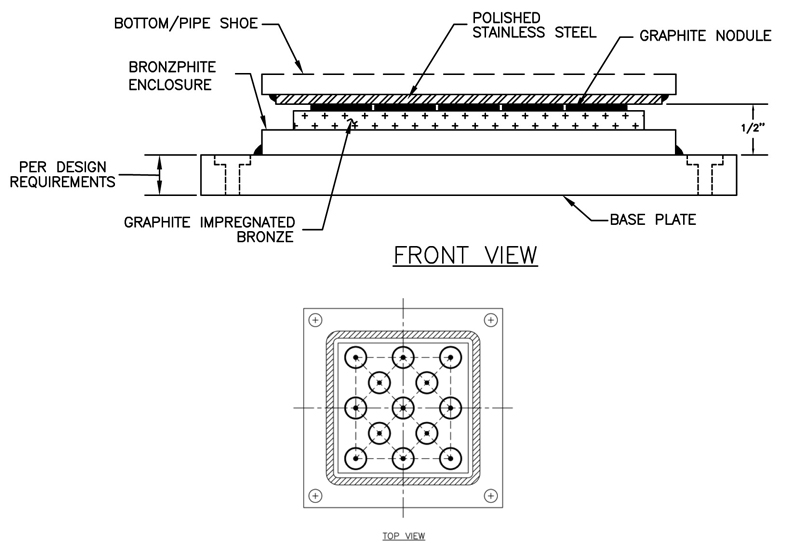

Welding: Generally for Bronzphite® slide plate, tack weld with the electric arc along the outside edge for a solid installation. Wherever full weld is desired, a one-quarter inch weld is used along the sides of the base plate to the substrate. The full weld would prevent seepage of water between the Bronzphite® bearing and the support structure.

The upper element is polished stainless steel. Both the upper and lower element can be tack weld with the electric arc along the outside edge for a solid installation to the bottom of the shoe, vessel, structural steel or trunnion.

Installation in Concrete: When installing Bronzphite® slide plate assemblies in concrete, anchor bolts will be integrated into the base plates for attachment to either the concrete form rebar structure or simply within the concrete itself.

Request a Quote