Types & Sizes

Fig. 83 Adjustable Clevis Hanger

Fig. 89: Clevis Hanger for Insulated Lines

Fig. 195: Roller Hanger

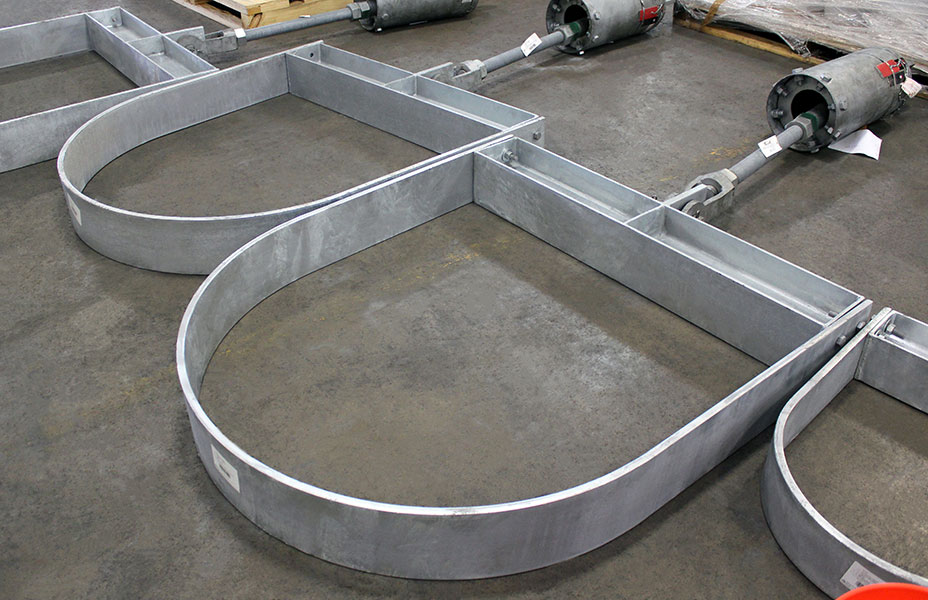

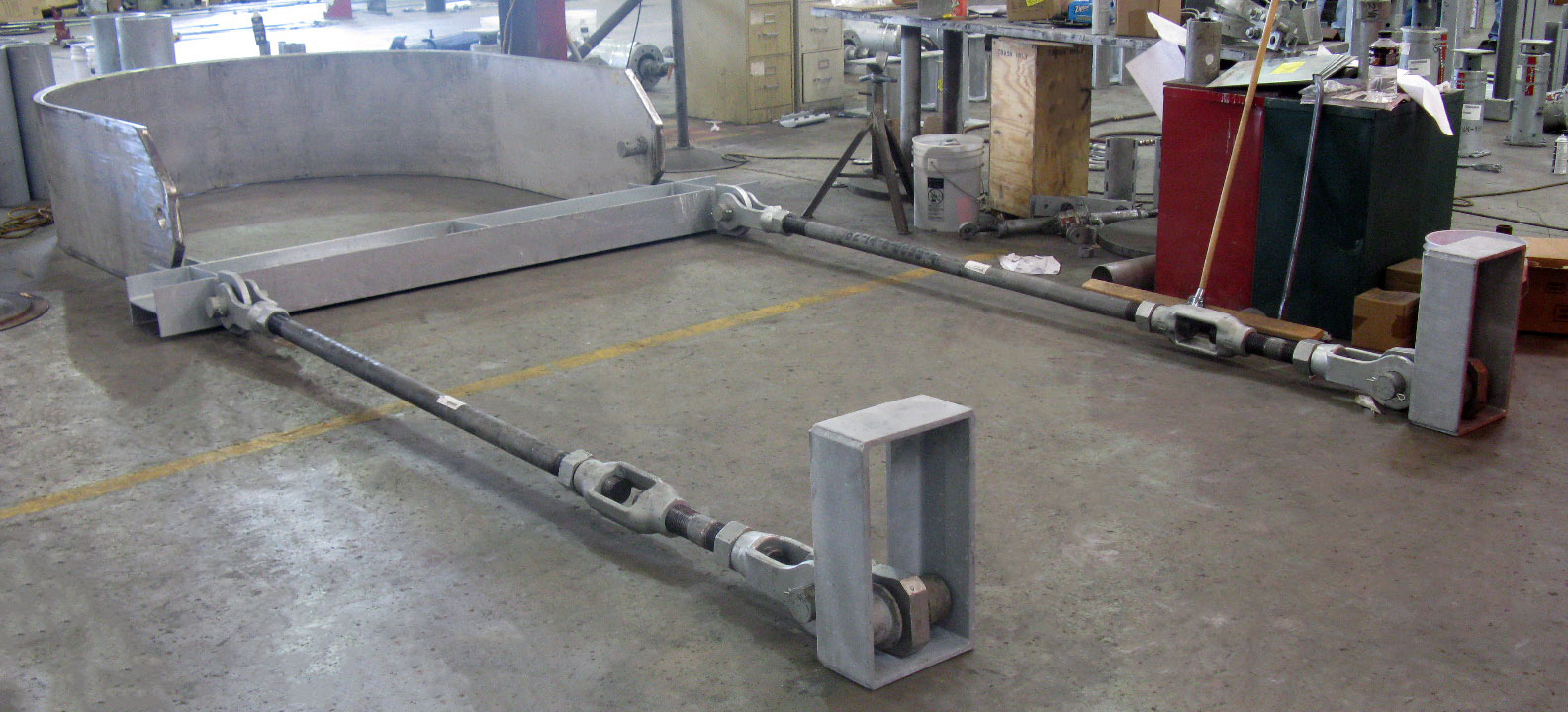

Fig. 200: Trapeze Roller Hanger

Technical Information

Methods of Protecting against Corrosion

Considering All Movement in Pipe Support Design

Comparative Corrosion Resistance Guide

Request A Quote