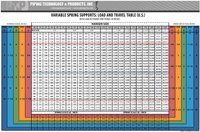

Load and Travel

INDUSTRY STANDARDS AND SPECIFICATIONS

The twenty-three columns designed 00, 10, 20, …, 220 identify the size and spring rate of coils used in the variables. The larger numbers have higher spring rates and are used to support greater loads. The recommended working range of loads for each size is shown between the red lines in the tables. The center of the working range is colored blue. Selecting variables with the loads within the working range provides a reserve above and below to ensure the coil can function inside the casing. In using the Load and Travel Table to choose the proper variable support, it is best to have the operating (hot) load and an amount and direction of expected movement. Variability is a key criterion in selecting the figure number and size. Variability is the percentage of change in the supporting force between the operating (hot) and installed (cold) positions calculated as shown:

Good practice, as specified by MSS SP-58, is to choose a support with variability less than or equal to 25%.

Always try to choose a variable with the operating (hot) load near the centerline (blue) of the working range in the Load and Travel Table. If you have a situation in which you cannot select a standard variable which has both the operating load and the installed load within the working range, contact us and we will help you determine alternatives.

The quality of the spring coil is very important to performance. Piping Technology buys coils from major suppliers with automated production facilities and Quality Assurance programs to provide the highest quality at competitive prices. We keep an extensive inventory of coils at all times so we can respond to the emergency requirements of our customers.

Most of our customers request neoprene coating for their spring coils, which we do in our facility. Neoprene protects the spring coil from many corrosives without affecting the flex life of the coil. In some cases, such as in a furnace installation, temperatures are too high for neoprene. We apply paint or other types of coatings for this situation. Neoprene is recommended only for operating temperatures up to 255°F.

Each variable spring we build is placed in a load cell and calibrated to the design load and movement. The nameplates show the position where the pressure plate meets the coil at the operating (hot) load and the installed (cold) load positions. The nameplate also shows PTP’s figure number, size, spring rate, and the customer’s designated mark or tag number.

SPRING NAME PLATES