Vibrations produced by rotating machinery are very common for industrial piping systems. Bracing devices can be used to cope with vibration. Hold downs are one of the most widely used pipe support devices to restrain or dampen pipe vibration. A common location for applying a hold down exists near a compressor. The objective is to limit vibration caused by rotating equipment in order to avoid damage to the surrounding piping system. The hold down restrains the vibration introduced by the compressor as it compresses the gases in the pipe line. Hold downs are effective for the control of vibration and/or movement.

Vibrations produced by rotating machinery are very common for industrial piping systems. Bracing devices can be used to cope with vibration. Hold downs are one of the most widely used pipe support devices to restrain or dampen pipe vibration. A common location for applying a hold down exists near a compressor. The objective is to limit vibration caused by rotating equipment in order to avoid damage to the surrounding piping system. The hold down restrains the vibration introduced by the compressor as it compresses the gases in the pipe line. Hold downs are effective for the control of vibration and/or movement.

Vibration Control: PT&P’s Capabilities

Pipe Technology & Products, Inc. can custom design and fabricate hold downs for any pipe size application. In additional to hold downs, PT&P also offers other types of vibration control devices to accommodate different pipe orientations and locations:

Types:

Anchor Type (PTP HD-1)

Anchor Type (PTP HD-1)

Generally used on pipe lines where little or no insulation is required

Temperature: 750°F

Anchor Type (PTP HD-1)

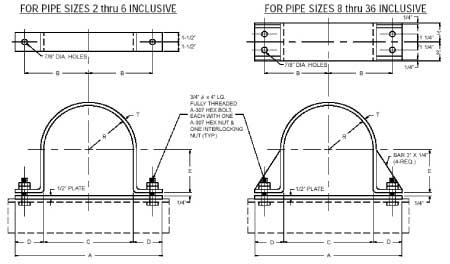

APPLICATION: The PTP Fig. HD-1 is our anchor type hold down. This hold down is generally used in pipe lines where little or no insulation is required.

Material: Carbon Steel

Finish: Black or galvanized

Temperature: 750°F Black Steel

Temperature: 200°C Galvanized Steel

|

Pipe Size

|

A

|

B

|

C

|

D

|

E

|

R

|

T

|

|

2

|

9 3/8

|

3 3/16

|

2 3/8

|

3 1/2

|

15/16

|

1 3/16

|

1/4

|

|

3

|

10 1/2

|

3 3/4

|

3 1/2

|

3 1/2

|

1 1/2

|

1 3/4

|

3/8

|

|

4

|

11 1/2

|

4 1/4

|

4 1/2

|

3 1/2

|

2

|

2 1/4

|

3/8

|

|

6

|

13 5/8

|

5 5/16

|

6 5/8

|

3 1/2

|

3 1/16

|

3 5/16

|

3/8

|

|

8

|

16

|

6 1/2

|

8 5/8

|

3 11/16

|

4 1/16

|

4 5/16

|

3/8

|

|

10

|

19

|

8

|

10 3/4

|

4 1/8

|

5 1/8

|

5 3/8

|

3/8

|

|

12

|

21

|

9

|

12 3/4

|

4 1/8

|

6 1/8

|

6 3/8

|

1/2

|

|

14

|

23

|

10

|

14

|

4 1/2

|

6 3/4

|

7

|

1/2

|

|

16

|

25

|

11

|

16

|

4 1/2

|

7 3/4

|

8

|

1/2

|

|

18

|

27

|

12

|

18

|

4 1/2

|

8 3/4

|

9

|

1/2

|

|

20

|

29

|

13

|

20

|

4 1/2

|

9 3/4

|

10

|

1/2

|

|

24

|

33

|

15

|

24

|

4 1/2

|

11 3/4

|

12

|

1/2

|

|

30

|

39

|

18

|

30

|

4 1/2

|

14 3/4

|

15

|

1/2

|

|

36

|

45

|

21

|

36

|

4 1/2

|

17 3/4

|

18

|

1/2

|

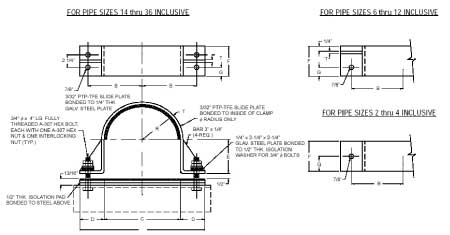

Anchor Type (PTP HD-2)

*generally used on compressor lines or similar applications with high temperature and massive thermal movement

*the clamp radius and the base are line with PTFE slide plate, allowing axial movement while restraining lateral movement.

*Temperature: 400°F

|

Pipe Size

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

R

|

T

|

|

2

|

9 3/8

|

3 9/16

|

2 1/2

|

3 9/16

|

3/4

|

2 1/2

|

1 1/4

|

1 5/16

|

1/4

|

|

3

|

10 3/4

|

4 1/8

|

3 5/8

|

3 9/16

|

1 5/16

|

2 1/2

|

1 1/4

|

1 7/8

|

1/4

|

|

4

|

11 3/4

|

4 5/8

|

4 5/8

|

3 9/16

|

1 13/16

|

2 1/2

|

1 1/4

|

2 3/8

|

1/4

|

|

5

|

13 7/16

|

5 7/16

|

5 11/16

|

3 7/8

|

2 7/8

|

2 1/2

|

1 1/4

|

2 15/16

|

3/8

|

|

6

|

14 1/2

|

6

|

6 3/4

|

3 7/8

|

2 7/8

|

3 1/2

|

1 1/4

|

3 7/16

|

3/8

|

|

8

|

16 1/2

|

7 9/16

|

8 3/4

|

3 7/8

|

3 7/8

|

3 1/2

|

1 1/4

|

4 7/16

|

3/8

|

|

10

|

18 5/8

|

8 1/16

|

10 7/8

|

3 7/8

|

4 15/16

|

3 1/2

|

1 1/4

|

5 1/2

|

3/8

|

|

12

|

21 3/4

|

9 5/8

|

12 7/8

|

4 7/16

|

5 15/16

|

3 1/2

|

1 1/4

|

6 1/2

|

1/2

|

|

14

|

23

|

10 1/4

|

14 1/8

|

4 7/16

|

6 9/16

|

6

|

1 3/8

|

7 1/8

|

1/2

|

|

16

|

25

|

11 1/4

|

16 1/8

|

4 7/16

|

7 9/16

|

6

|

1 3/8

|

8 1/8

|

1/2

|

|

18

|

27

|

12 1/4

|

18 1/8

|

4 7/16

|

8 9/16

|

6

|

1 3/8

|

9 1/8

|

1/2

|

|

20

|

29

|

13 1/4

|

20 1/8

|

4 7/16

|

9 9/16

|

6

|

1 3/8

|

10 1/8

|

1/2

|

|

24

|

33

|

15 1/4

|

24 1/8

|

4 7/16

|

11 9/16

|

6

|

1 3/8

|

12 1/8

|

1/2

|

|

30

|

39

|

18 1/4

|

30 1/8

|

4 7/16

|

14 9/16

|

6

|

1 3/8

|

15 1/8

|

1/2

|

|

36

|

45

|

21 1/4

|

36 1/8

|

4 7/16

|

17 9/16

|

6

|

1 3/8

|

18 1/8

|

1/2

|

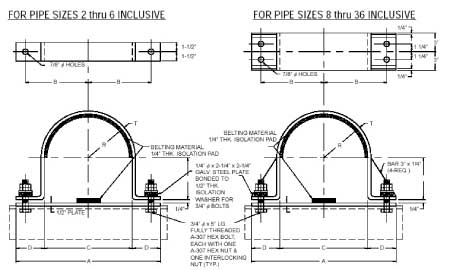

Anchor Type (PTP HD-3)

*generally used on compressor lines or similar applications with low thermal movement

*the clamp radius is lined with a belting material designed to absorb shock from vibration

*Temperature: 200°F

*belting material remains impervious to heat up to 200°F

|

Pipe Size

|

A

|

B

|

C

|

D

|

E

|

R

|

T

|

|

2

|

9 7/8

|

3 7/16

|

2 7/8

|

3 1/2

|

1 3/16

|

1 7/16

|

1/4

|

|

3

|

11

|

4

|

4

|

3 1/2

|

1 3/4

|

2

|

3/8

|

|

4

|

12

|

4 1/2

|

5

|

3 1/2

|

2 1/4

|

2 1/2

|

3/8

|

|

6

|

14 1/8

|

5 9/16

|

7 1/8

|

3 1/2

|

3 5/16

|

3 9/16

|

3/8

|

|

8

|

16 1/2

|

6 3/4

|

9 1/8

|

3 11/16

|

4 5/16

|

4 9/16

|

3/8

|

|

10

|

19 1/2

|

8 1/4

|

11 1/4

|

4 1/8

|

5 3/8

|

5 5/8

|

3/8

|

|

12

|

21 1/2

|

9 1/4

|

13 1/4

|

4 1/8

|

6 3/8

|

6 5/8

|

1/2

|

|

14

|

23 1/2

|

10 1/4

|

14 1/2

|

4 1/2

|

7

|

7 1/4

|

1/2

|

|

16

|

25 1/2

|

11 1/4

|

16 1/2

|

4 1/2

|

8

|

8 1/4

|

1/2

|

|

18

|

27 1/2

|

12 1/4

|

18 1/2

|

4 1/2

|

9

|

9 1/4

|

1/2

|

|

20

|

29 1/2

|

13 1/4

|

20 1/2

|

4 1/2

|

10

|

10 1/4

|

1/2

|

|

24

|

33 1/2

|

15 1/4

|

24 1/2

|

4 1/2

|

12

|

12 1/4

|

1/2

|

|

30

|

39 1/2

|

18 1/4

|

30 1/2

|

4 1/2

|

15

|

15 1/4

|

1/2

|

|

36

|

45 1/2

|

21 1/4

|

36 1/2

|

4 1/2

|

18

|

18 1/4

|

1/2

|