Externally pressurized expansion joints, also known as X-flex expansion joints, are engineered marvels designed to absorb large axial movements in piping systems. Unlike traditional expansion joints that rely solely on internal pressure to compensate for thermal expansion, X-flex joints employ an external pressure chamber to achieve a balanced and controlled expansion. This innovative design offers enhanced flexibility and durability, making them ideal for a wide range of applications across industries.

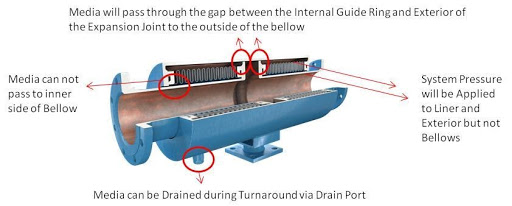

One of the standout features of externally pressurized expansion joints is their ability to maintain constant pressure on the bellows. This is achieved through a carefully engineered system that balances the internal pressure against the external pressure, effectively counteracting the forces acting on the joint during operation. The result is a smoother and more controlled expansion and contraction process, and with properly sized anchors it minimizes stress on the piping system.

The bellows are fabricated from high-quality metals, such as stainless steel or other alloys, ensuring corrosion resistance and longevity. The external pressure chamber is designed to hold the line pressure and act as an external cover for the bellows, it can also be designed to withstand harsh environmental conditions.

More About Externally Pressurized Expansion JointsView Product Page

The technical features of US Bellows’ externally pressurized expansion joints make them versatile and well-suited for a wide range of industrial applications. In the petrochemical sector, these joints effectively manage thermal expansion and contraction in pipelines, ensuring the structural integrity of the system. Power generation facilities benefit from US Bellows’ advanced solutions by absorbing thermal movements, enhancing both efficiency and safety.

The installation of X-flex expansion joints requires precision and expertise to ensure optimal performance. Proper alignment and anchoring are essential to guarantee that the joint functions as intended, effectively absorbing movements and mitigating stress on the piping system. Regular inspection and maintenance are also crucial to identify any signs of wear or fatigue, preventing potential issues before they escalate.

US Bellows, with its technical expertise and commitment to innovation, stands as a key player in providing reliable and cutting-edge solutions that contribute to the longevity and reliability of critical infrastructure across various industries.