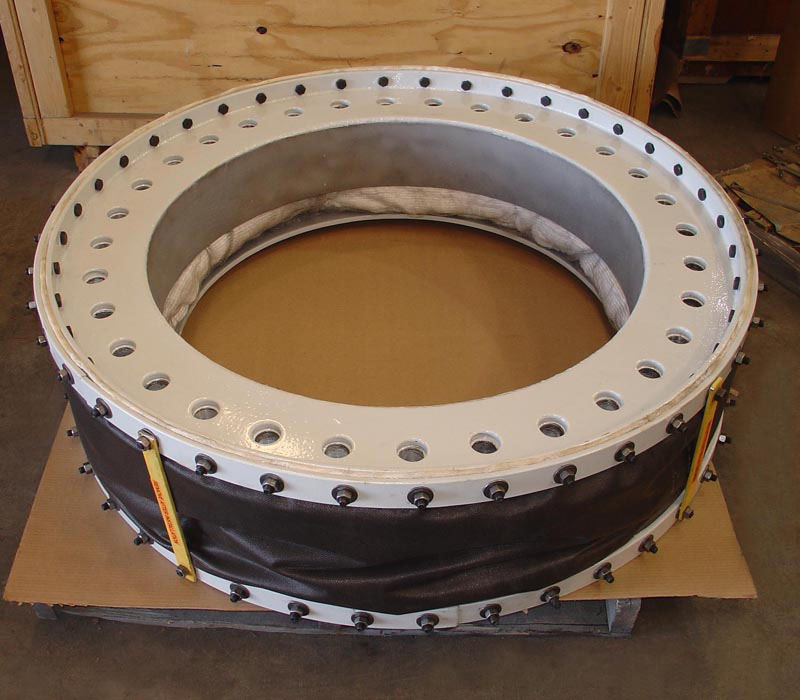

Fabric expansion joints are often used in ductwork to transfer hot gases under low pressures. These expansion joints normally consist of fabric belting material and a metal frame. Combining different insulation layers, which are made of different fabrics, help the fabric belt and insulation layers to adapt to the temperatures and pressure in the system. Insulation pillows, accumulation barriers or flow liners are used to protect the fabric belt in cases where the fabric material needs to be additionally protected. The fabric expansion joint frame connection with channel ends can be welded or bolted to the duct ends.

For example, take ductwork for the transfer of hot, low-pressure media in power plants. In this kind of large combustion process, we have “flow of air” and “exit gas”. In this kind of large combustion process, we have “flow of air” and “exit gas”. In such ducting systems, expansion joints made of fabric can perform a double function. To compensate for thermal growth of the duct and compensate for minimum duct misalignments on expansion joint connection points.

This type of expansion joint can be inserted into the parts of the ductwork where movement occurs. The advantage compared to metal expansion joints is reflected in the absorption of larger movements and the absence of spring loads that could be transferred to other parts of the ductwork. By reducing the thermally induced stresses in the ducting, other elements of the ductwork, such as supports and related equipment, will be exposed to lower stresses.

U.S. Bellows, manufacturing tradition stretches back to half of the last century. The team of engineers at PT&P / U.S. Bellows has extensive experience in assessing operating conditions and designing expansion joints. The types of frames manufactured at U.S. Bellows have features designed to reduce the adverse effects caused by pressure, temperature and turbulence of various media. Fabric expansion joints, designed this way, have a long service life.

The fabric belt deforms depending on the movement of the duct. The fabric must perform its main task without tearing. The fabric is sometimes exposed to high temperatures and/or corrosive media, so it may need to be changed periodically.

More About Fabric Expansion Joints View Product Page