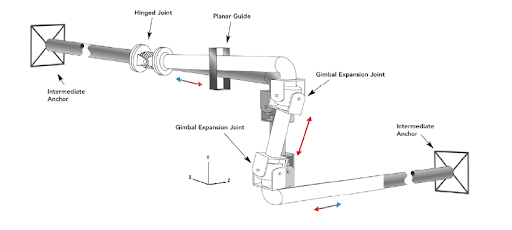

When it comes to piping systems, expansion joints play a critical role in their performance and longevity. One type of expansion joint that is commonly used is the gimbal expansion joint. It is a flexible piping element designed to absorb and relieve movement, vibration, and expansion in pipelines. The gimbal expansion joint is often used in applications where the pipeline needs to change direction or navigate around obstacles or where space is limited.

A key advantage of gimbal expansion joints is their ability to absorb and offset the effects of expansion and contraction in pipelines when used in sets of two or three. As materials flow through a pipeline, they undergo temperature, pressure, and flow changes that can create stress and potentially cause pipeline damage such as cracks or ruptures. The gimbal expansion joint mitigates this risk by enabling the pipeline to expand and contract freely without encountering excess stress.

More About Gimbal Expansion JointsView Product Page

Another common issue in piping systems is vibration, which can arise from the flow of materials, pressure fluctuations, or nearby equipment activity. If not properly managed, this vibration can harm both the pipeline and associated equipment. Gimbal expansion joints may effectively dampen these vibrations to prevent damage.US Bellows can help you decide if a Gimbal expansion joint is a suitable solution to your vibration problem.

The gimbal mechanism in a gimbal expansion joint allows for angular movement in two directions, while containing the full pressure thrust, which is especially important in applications where the pipeline needs to change direction or where there is a high degree of movement. The gimbal mechanism allows the pipeline to move freely, without experiencing any stress, which helps to maintain the integrity of the pipeline.

Choosing the appropriate construction material is a vital factor to consider when selecting a gimbal expansion joint. It is imperative to ensure that the materials used for both the bellows and gimbal are compatible with the materials being transported, as well as the temperature and pressure conditions. Commonly used materials for the bellows of gimbal expansion joints include stainless steel, Inconel, and Monel, each offering unique advantages and properties. The selection of the material will depend on the specific application requirements.

Since the 1960s, U.S. Bellows has supplied expansion joints and was acquired by PT&P in 1997. PT&P has a distinctive position in the expansion joint service industry, being the sole global bellows manufacturer with extensive expertise in pipe stress engineering and production of both expansion joints and engineered pipe supports. This engineering proficiency in expansion joints, pipe stress, and engineered pipe supports has enabled PT&P/US Bellows to create numerous custom designs for individual customer specifications. Furthermore, PT&P/U.S. Bellows is a member of the Expansion Joint Manufacturer’s Association, which is responsible for setting expansion joint engineering standards, along with only 13 other global members.