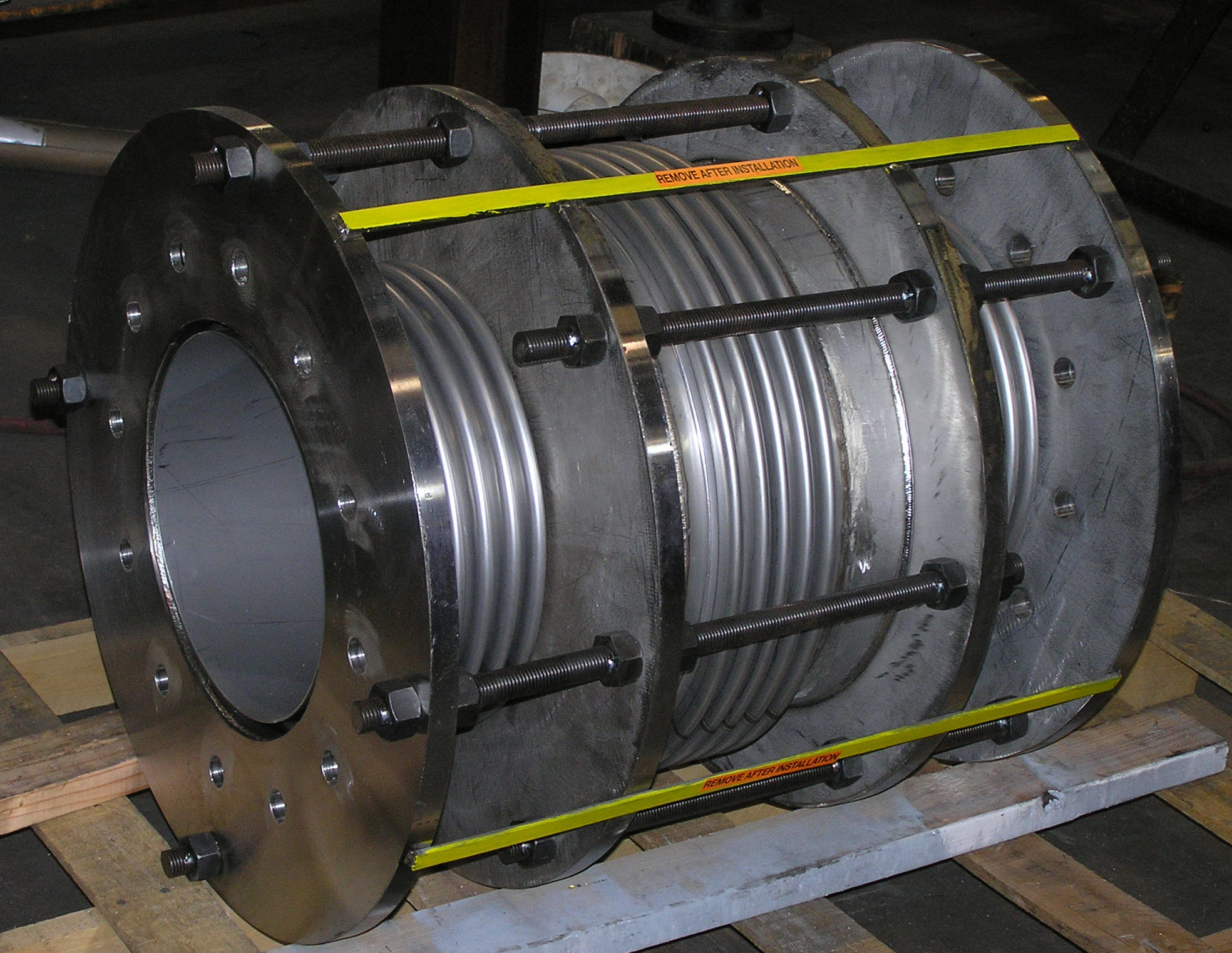

In-Line Pressure Balanced Expansion Joints stand out as specialized solutions within piping design, specifically designed for precise control of axial movement, lateral deflection, and angular rotation while fully retaining pressure thrust. Their technical features, including pressure balancing and structural components, make them indispensable in various industries. US Bellows, as a leader in the field, continues to provide cutting-edge solutions, underscoring the practical applications and technical advancements of In-Line Pressure Balanced Expansion Joints.

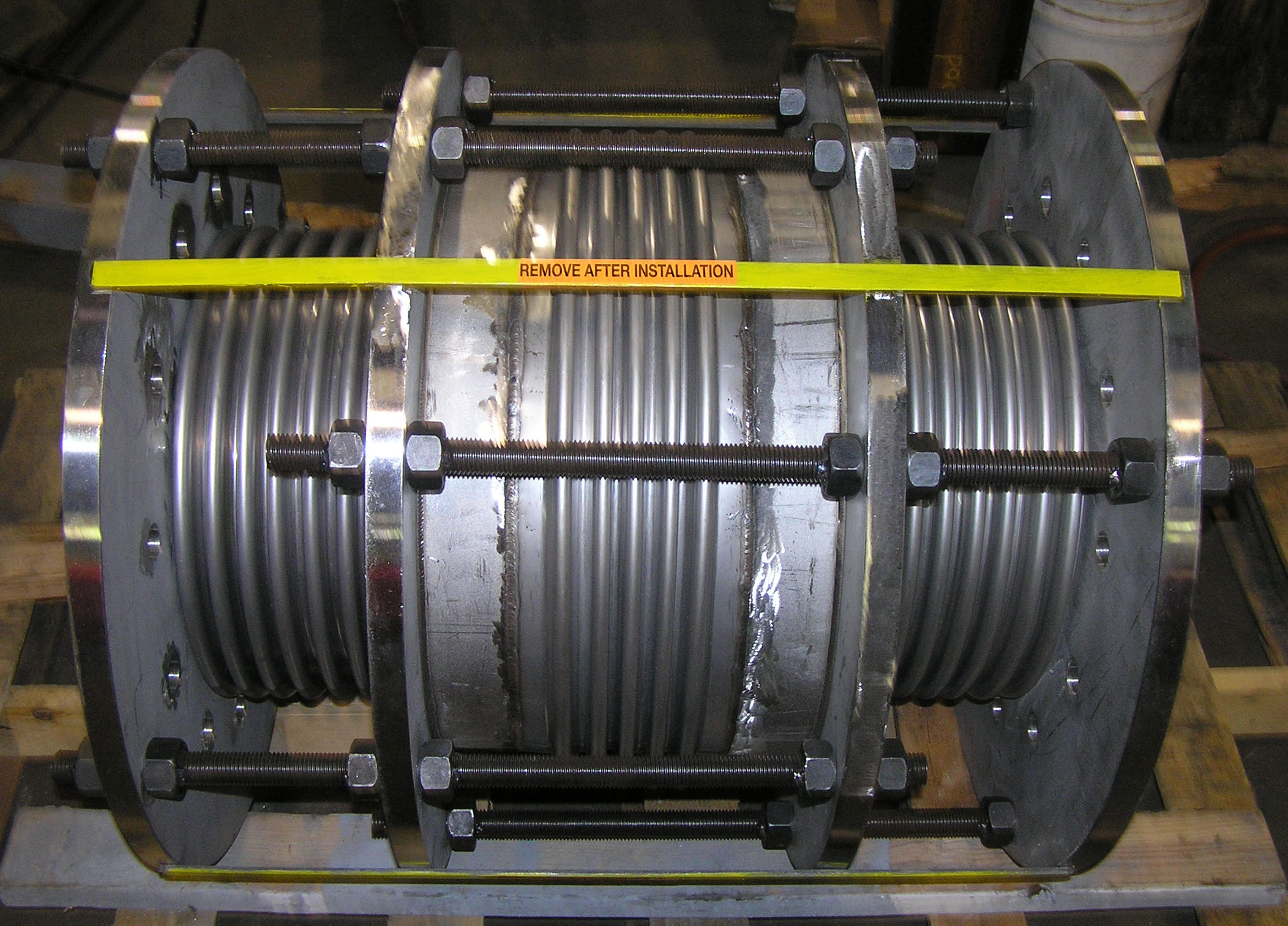

In-Line Pressure Balanced Expansion Joints are engineered to meticulously handle axial movement pressure forces within piping systems, without the need of pipe anchors. The core principle involves balancing internal and/or external pressures, ensuring a controlled expansion and contraction process. This design minimizes stress on the piping infrastructure, enhancing overall durability and reliability.

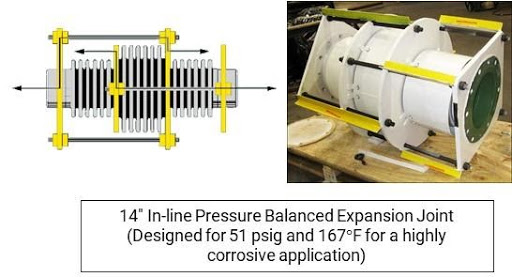

Quick Fact: Is the bellow really being compressed or is the entire bellow is moving?

When there is an axial movement, the in-line bellows will start compressing and the balancing bellows will extend and vice versa. Both bellows will be moving.

See corresponding video here.

More About In-Line Pressure Balanced Expansion JointsView Product Page

The success of In-Line Pressure Balanced Expansion Joints relies on the precision engineering and design of key components. These include bellows, liners, tie rods, and other structural elements, each serving a specific function. Bellows, constructed from materials like stainless steel or nickel alloys, offer corrosion resistance and structural resilience. The incorporation of tie rods further reinforces the expansion joint, by balancing the pressure forces of the pipeline during operation.

In-Line Pressure Balanced Expansion Joints find extensive applications across various industries due to their versatility. In petrochemical plants, they effectively manage axial movements, accommodating thermal expansions and contractions within high-temperature pipelines. Power generation facilities leverage their pressure balancing capabilities to optimize efficiency, minimize cost by limiting the use of anchors and mitigating stress from dynamic loads and thermal fluctuations.