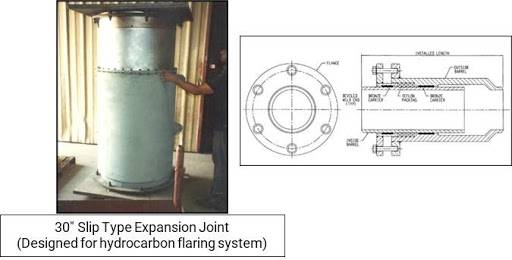

The technical functionality of Slip Type Expansion Joints revolves around their capacity to facilitate axial movement while maintaining a sealed connection between two adjacent pipe sections. These joints are designed with a slip-type arrangement, allowing for controlled axial displacement while preventing leakage. The materials chosen the sealing materials, play a pivotal role in ensuring resistance to corrosion, fatigue, wear and the various environmental factors the joints may encounter during operation.

Slip Type Expansion Joints find practical application in industries where dynamic operational conditions necessitate the accommodation of thermal expansions and contractions. These joints are particularly useful in systems where axial movement is anticipated, providing flexibility without compromising the structural integrity of the overall piping system. Whether in power plants, petrochemical facilities, or industrial processing units, Slip Type Expansion Joints play a critical role in maintaining system reliability. One thing to note is that periodic maintenance may be needed on the sealing interface for optimal performance and operation.

More About Slip Type Expansion JointsView Product Page

Proper alignment and secure anchoring are essential to allow the joints to function. Precise positioning of expansion joints within the piping system, coupled with secure fastening, contributes to the prevention of premature wear and tear. Additionally, thorough inspection, maintenance and adherence to manufacturer guidelines during installation are crucial for maximizing the service life and reliability of Slip Type Expansion Joints.

US Bellows offers a comprehensive range of Slip Type Expansion Joints tailored to meet the specific demands of dynamic industrial environments.