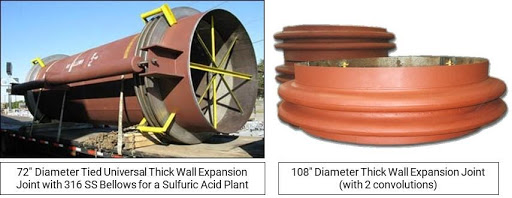

Similar to thin wall bellows, the foundation of Thick Wall Expansion Joints lies in a precision-engineered design tailored to counter thermal variations in industrial piping systems. Crafted with a focus on structural robustness, they ensure resilience against high temperatures and operational pressures. Thick Wall Expansion Joints offer a cost-effective solution for extensive piping systems with large diameters and low pressure. Based on the application, materials can be chosen based on the media and specific temperature conditions.

As a leader in the expansion joint industry, US Bellows pioneers advancements in Thick Wall Expansion Joints, ensuring optimal performance in diverse industrial applications.

More About Thick Wall Expansion JointsView Product Page

The defining characteristic of Thick Wall Expansion Joints is their substantial wall thickness, allowing them to absorb thermal expansions, making them suitable for industries with extreme conditions. The effectiveness relies on the precise selection of structural components. Beyond the thick-wall bellows, these joints can incorporate flanges, liners, and tie rods, each serving a crucial role. Material choices can be carbon steel, stainless steels and including corrosion-resistant nickel alloys, bolster the joints against industrial environments.

The versatility of Thick Wall Expansion Joints positions them as indispensable components across diverse industries. In petrochemical plants, they manage thermal expansions in high-temperature pipelines, contributing to overall structural integrity. Power generation facilities benefit from their robustness, absorbing thermal stresses induced by dynamic loads and temperature fluctuations. In precision-demanding manufacturing environments, these joints play a pivotal role in sustaining stability, handling thermal expansions without compromising structural integrity.