Frequently Asked Questions

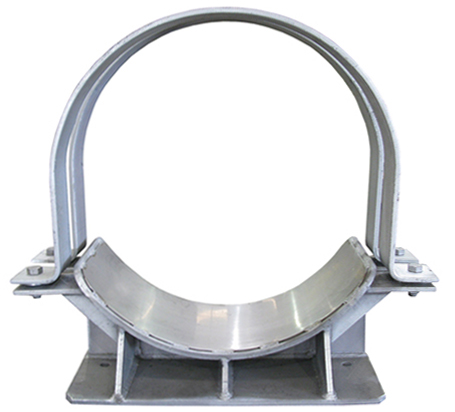

A pipe saddle is a structure consisting of a saddle and integral base that is used to support the pipe by transmitting the load or forces to the adjacent structure.

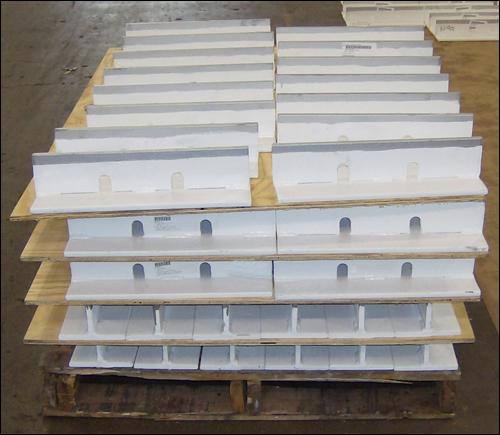

78″ Heavy Duty Pipe Saddles

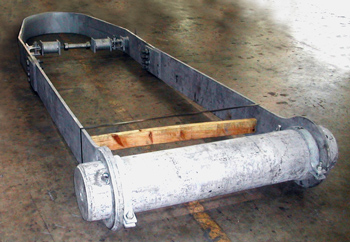

A pipe anchor support is a rigid device that completely restricts pipe movement in all three dimensions while bearing the weight, side, and thrust loads. It is designed to prevent essentially all pipe rotation and displacement at the point of application.

Cold Insulated Pipe Anchors with Axial Stops

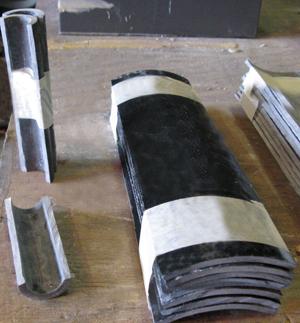

A cold shoe refers to a support component which incorporates an insulating material that attaches directly to the pipe and also functions as a load bearing component transferring the load to a point outside of the insulating enclosure.

Cryogenic Supports (Cold Shoes) with Permali Insulation

A saddle support is a support consisting of a stanchion that utilizes a curved section for cradling the pipe.

Adjustable Pipe Saddle Supports

Polyurethane is a light-weight material used primarily in low-temperature applications to provide both a load bearing function and insulating function for the pipe. Some of the specific design parameters of polyurethane are as follows:

- Temperature Range-Ambient to -300 DEG. F

- Compressive Strength-220 PSI to 911 PSI (Dependent on Density)

- Tensile Strength-200 PSI to 800 PSI

Cryogenic Pipe Supports insulated with 20 PCF High Density Polyurethane Foam

Pipe shoes are connected to a beam depending on their function whether or not they are a support, guide or anchor. In the case of a support, the shoe would rest on top of the supporting steel structure. In the case of a guide, in most instances the secondary supporting base plate/guide combination would be welded to the supporting structure and the shoe would rest upon the base. In the case of anchor supports, in most instances, the base of the shoe is welded directly to the supporting steel.

Insulated Pipe Shoe with Guides Resting on a Steel Structure

A pipe shoe is a structure consisting of a saddle and integral base that is used to support the pipe by transmitting the load or forces to the adjacent structure.

Custom Elevated Pipe Shoe-Clamp

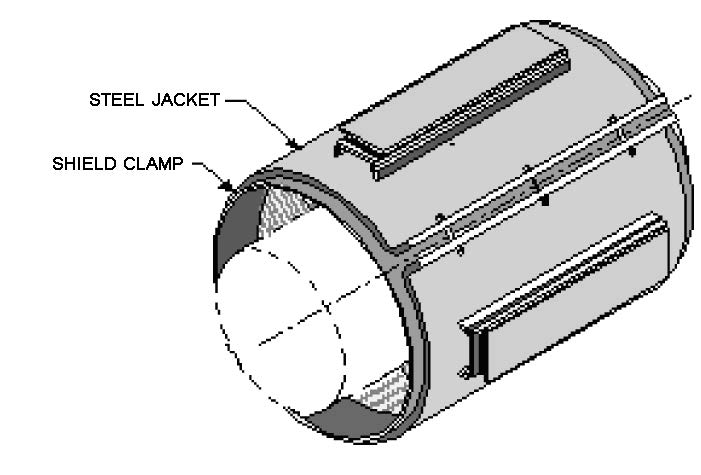

A pipe clamp is a pipe attachment which clamps around the pipe to connect the pipe to the remainder of a pipe hanger assembly. Pipe clamps are recommended for the suspension of cold pipe lines and may or may not be insulated.

3 Piece Pipe Clamp

Pipe straps are curved structures generally used to either guide or anchor a pipe and are usually attached to the surrounding structural steel components.

Pipe Straps for a Chemical Plant

There are two options for attaching spider guides (or PTP Figure 6, Cylinder Pipe Guides) to structural steel. All spider guide assemblies are provided with a stationary outer sleeve which can be mounted to the structural steel by either bolting or welding as required.

Spider Guides

You can utilize pipe shoes on un-insulated lines simply to support the pipe or transfer the pipe load to other support components.

Permali Cold Shoes for Carbon Steel Pipe

The standard practice when supporting vertical pipe runs is to utilize a riser clamp assembly in conjunction with pipe lugs welded onto the pipe outside diameter. The load is transferred to the riser clamp bolts via rigid rod hanger assemblies, spring assemblies, etc.

Riser Clamp

Anchors prevent movement in all directions.

Anchors will restrict movement in all directions and will also restrictthe rotation of the pipe as well. In the stress analysis, we may see loads inall three directions which will tell us how “strong” the anchor device has to be.

Cold Shoe Anchors

In order to use pipe rollers in this application, an insulated pipe support has to manufacture as part of the roller assembly. We use a higher density insulation so that the insulation will not be crushed – 10 lb, 14 lb, 20 lb, or 32 lb, depending on the load.

Eight Polyurethane Pipe Rollers for a Gas Plant

The thickness of the insulation is based on the amount of heat transfer that you would like to reduce.

Marinite Sections for Hot Shoes

If you have a sloped pipe shoe on the line, the bottom of the shoe must be parallel with the spring to support the load. You can slope the shoe where it comes in contact with the pipe.

F-Type Variable Spring Support

A hot shoe is name that refers to insulated supports which cradle the pipe and are intended for operation at high temperatures exceeding 200 degrees Fahrenheit.

Hot Shoes

The area where the pad is to be affixed on the pipe and the inside surface of the wear pad must both be sanded first in order to create a rough surface for installation. Then an epoxy adhesive is generously applied to the inside surface of the wear pad. Make sure that the pipe surface is clean and free of all environmental debris and affix the wear pad to the pipe. Finally, add an additional amount of glue around the edges of the wear pad and apply temporary straps around the pipe and pad to tighten the contact between the pad and pipe while it is drying.

>Preparing the FRP pad for Installation

FRP wear pads are used as corrosion protection on uninsulated pipes and can be secured to FRP pipes to provide an extra layer of pipe and thereby extend the life of the pipe. FRP wear pads also eliminate metal to metal contact between the pipe and its metal supporting structure.

>FRP Wear Pads

At Piping Technology, we fabricate both FRP wear pads to be used on metallic and non-metallic pipe. We also design and fabricate pipe supports such as saddles and clamps that will be installed on FRP piping systems.

Pipe shoes are connected to a beam depending on their function whether or not they are a support, guide or anchor. In the case of a support, the shoe would rest on top of the supporting steel structure. In the case of a guide, in most instances the secondary supporting base plate/guide combination would be welded to the supporting structure and the shoe would rest upon the base. In the case of anchor supports, in most instances, the base of the shoe is welded directly to the supporting steel.

Insulated Pipe Shoe with Guides Resting on a Steel Structure

We recommend that you use a non-metallic wear pad or FRP pad that is fabricated from fiberglass reinforced plastic and is secured to the pipe using an epoxy adhesive. Another option is the use of a neoprene lining on the clamp which also prevents metal to metal contact.

See Figure 182 in our Online Catalog.

Pipe Clamps with Neoprene Lining

Gussets are added reinforcement plates used to strengthen the overall structure of the shoe and provide either extra load carrying capacity or added strength when the pipe shoe is used as a guide or anchor.

Guided Pre-Insulated Pipe Anchor with Gussets

Most high temperature supports (i.e. hot shoes) do not require any type of service or maintenance. If a shoe is damaged, it would need to be completely removed from service and refurbished.

High Temperature Supports (Hot Shoes)

Stainless steel pipe shoes, like others of similar construction but different materials, would be supported by the available surrounding structural steel elements in the piping system.

Split T Pipe Shoes fabricated from Carbon Steel, Alloy Steel, and Stainless Steel

The primary difference between insulated supports for cold temperatures and hot temperatures lies within the insulation materials themselves. Cold supports typically utilize polyurethane foam as an insulating material, and hot pipe supports typically use combinations of calcium silicate and marinate materials.

Cold Insulated Pipe Shoes for an LNG Plant

High Temperature Insulated Pipe Support