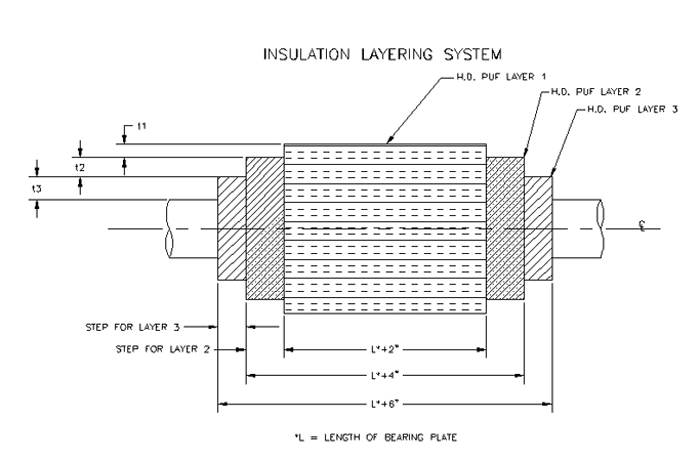

At Piping Technology and Products, we recommend multiple layers for cold shoe supports that have a total insulation thickness of four inches or greater.

In the field, cold shoes are typically mated with existing line insulation. Due to the low temperature of the pipe, moisture from the ambient air can be drawn to the pipe through gaps that may exist between the cold shoe and the line insulation. At lower temperatures, where thicker insulation is required, there is greater opportunity for moisture to be drawn to the pipe. This is because of the increased single mating surface area between the line insulation and the cold shoe.

A solution that eliminates this potential problem is providing multiple mating surfaces between the line insulation and the pipe support. Hence: When insulation thickness is four inches and greater, multiple layers provide an improved moisture seal due to steps between the different layers.

To determine the thickness of each layer, refer to our suggested layering chart on the following page. To use this table, reference the total insulation thickness to determine how many layers are suggested and how thick each layer should be.

Example: A four inch (4″) pipe that requires five inches of insulation: Referring to PT&P’s suggested layering chart, two layers are required. The first layer (inner layer) thickness is suggested to be 2″ and the second layer (the outer layer) is suggested to be 2″ thick.

Piping Technology and Products can tailor a layering system to meet the customer’s requirements. The included layering chart is only a guideline.