Resources

Resources

F-Type Variable Spring Supports for a Chemical Plant and Refinery in Singapore

An assortment of standard variable spring supports were manufactured ranging in size from 8-5/8″ to 12-3/4″ dia. with installed heights ranging from 9-7/16″ to 18-1/8″. The F-Type pipe hanger assembly is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The various springs shown are designed for operating conditions ranging from loads of 1750 lb. with .02″ travel to 21,280 lb. loads with .13″ travel. As with all of our variable supports, these were quality checked with a 100% spring coil deflection test and a load cell calibration to set the assembly at the prescribed installed load.

Do you see a need for variable springs in your piping system? Let us price them for you!

Take a Look into the Past: Insulated Pipe Supports

Check out our most recent article that looks at the history of insulated pipe supports through the past 100 years. Learn about the developments made in the 1950’s and 1960’s that introduced the use of “Foam Glass”, a lightweight material that is manufactured primarily from recycled glass and used in the design of insulated pipe supports. Later, polyurethane was developed to provide greater load carrying capabilities. Read the full article on the:

Want to learn more about pre-insulated supports? Instantly view a past pre-insulated support webinar now!

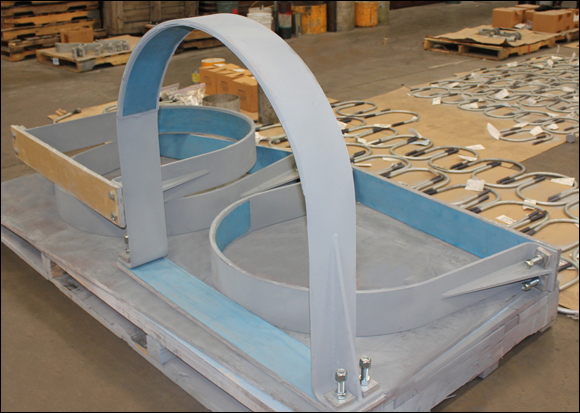

Cryogenic Supports with Permali® Insulation for an LNG Plant in Abu Dhabi

Over 30 cryogenic supports fabricated from a combination of carblon steel, permali® block and stainless steel were manufactured for an LNG plant in Abu Dhabi. The shoes measures 18″ x 14″ x 12″ and are designed for 10″ of thermal movement and temperatures as low as -167°C. The cold shoes are coated with a custom paint job and went through standard testing prior to shipment.

Have a need for cryogenic supports in a current or upcoming project? Get a quote today!

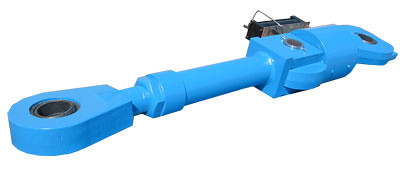

Snubbers: A General Overview

We recently posted a new Snubber article on our website. It provides a technical look into both hydraulic and mechanical snubbers – how they are used in a piping system and how they function. Most importantly, the article tells you the difference between various types of snubbers which is helpful in choosing the appropriate snubber for your piping system needs.

Want to learn more about snubbers? Watch a recording of a past snubbers webinar now!

Constant Spring Supports vs. Variable Spring Supports

Ever wonder what makes a constant spring support different from a variable spring support? How does each one function? How do they support loads and allow for movement in a pipeline? Check out our new spring support article that provides all the answers to these questions and more.

Want to learn more about constants? Instantly view a past constants webinar now!

What is galvanized coating?

Galvanized coating is a type of sealant to protect a pipe support against corrosion. It has two advantages over a zinc coating. During galvanizing, the molten zinc reacts with the carbon steel to form layers of zinc/iron alloys. The alloy layers between have increased hardness to provide mechanical (barrier) protection and because of their zinc content they are also anodic relative to carbon steel. The hardness of these alloy layers provides much more protection from scratches than paint can provide. This is important for most pipe supports applications.

Constant Spring Assemblies with Galvanized Coating

How does a toroidal expansion joint work?

A toroidal convolution consists of a circular tube (or torus) wrapped around weld ends or pipe ends having a gap at the I.D. to permit axial stroke. A toroidal expansion joint may consist of one convolution, or multiple convolutions. This joint is also known as an Omega bellows expansion joint for it resembles the Greek letter Omega. Most toroidal bellows are hydraulically formed which requires high pressure. Others are free formed, similar to blowing up a balloon. More accurate convolution shapes may be formed into toroidal dye cavities. Since this forming pressure is high, pressure resistance is also high.”U” shaped bellows cause a bending stress due to the pressure load on the convolution side wall. This generally determines the maximum pressure, however the toroid contains only membrane stress thus determining the maximum pressure. Due to the toroidal shape, deflection is limited. With “U” shaped convolutions, more deflection can be achieved but allowable pressures are lower.

Toroidal Bellow Expansion Joint

How many expansion joints should be used in a pipe?

The number of expansion joints used on a pipe depends on the length of the pipe, the pressure, the temperature, and the size. Upon knowing these design conditions, we can inform you of the number of expansion joints the pipeline requires.

Where do we use expansion joints in piping?

Using expansion joints on piping depends upon the configuration of the piping where you will place the expansion joint to absorb thermal expansion or contraction.

How do you service test an expansion joint?

Expansion joints are maintenance free. They can only be tested if the expansion joint is supplied with 2-ply testable bellows using vacuum or air pressure testing.

How do you perform a burst test?

The burst test is primarily conducted on bellows. Normally, hydraulic pressure is slowly increased until failure occurs. Based on the burst test results, a safety factor is applied. This establishes the ultimate pressure rating.

Burst Testing

What is burst testing?

The objective of the burst test is to determine the ultimate pressure resistance. This test is primarily conducted on bellows. Normally, hydraulic pressure is slowly increased until failure occurs. Based on the burst test results, a safety factor is applied. This establishes the ultimate pressure rating.

Burst Testing

What are EDI capabilities?

EDI stands for Electronic Data Interchange. PT&P regularly conducts electronic data interchange with customers. We dedicate an in-house team of software developers and integrators to setup intra-company electronic processes that increase data accuracy and reduce cycle time.

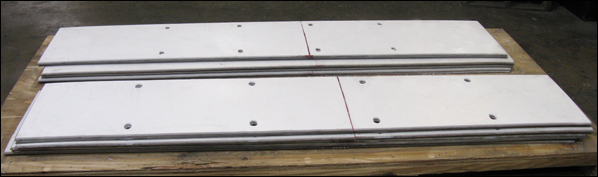

Where are bearing plates typically used?

Bearing plates are used on a stationary support element and a moving pipe support component to provide a low-coefficient of friction between the two.

Stainless Steel Slide Plates Welded on Variable Springs

How do you install slide plates?

For PTFE, 25% Glass Filled Slide Plates:Prior to Welding: Locate the slide plate base in the appropriate position on the existing steel surface. Place a protective covering on the PTFE, 25% glass filled. Where seal welding is not required, follow the diagram shown which indicates 1/8 inch thick fillet weld, 1 inch long every 4 inches around entire perimeter of the base. For welding, use GMAW 0.035 wire or SMAW 3/32 inch stick.Where full seal welding is required, use a similar pattern of welding until a full weld is obtained. This method will prevent damage to the PTFE, 25% glass filled. (A full weld will help prevent seepage of water between the slide bearing plate and the support structure.) Avoid overheating, which may destroy the bonding of the PTFE, 25% glass filled to the base plate.Installation in Concrete: Secure the top and bottom elements together with paper adhesive tape. Then attach the bottom element anchor bolts with wire to the form. After the bottom pour is made, repeat on top element. During the first expansive cycle, the tape will break. For Graphite and Bronzphite Plates – see link below:

How do you bond PTFE to metal?

PTFE Slide Plates Welded to Metal Pipe Saddles

What is the use of a slide plate?

The purpose of slide plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

Slide Plates on Pipe Clamps for Low Coefficient of Friction

What is a PTFE bearing pad?

A PTFE bearing pad is a slide plate made up of PTFE, 25% glass filled, material that provides a low coefficient of friction for most combinations of temperature and load. For most applications, PTFE, 25% Glass Filled, is adequate when the temperature is less than 400 degrees F.

What is PTFE?

PTFE is also know as polytetrafluoroethylene. It is used as a component of slide plates and functions as a low-coefficient of friction between a stationary support element and the moving pipe support component.

PTFE Slide Plates