Types & Sizes

Technical Information

Installation & Maintenance

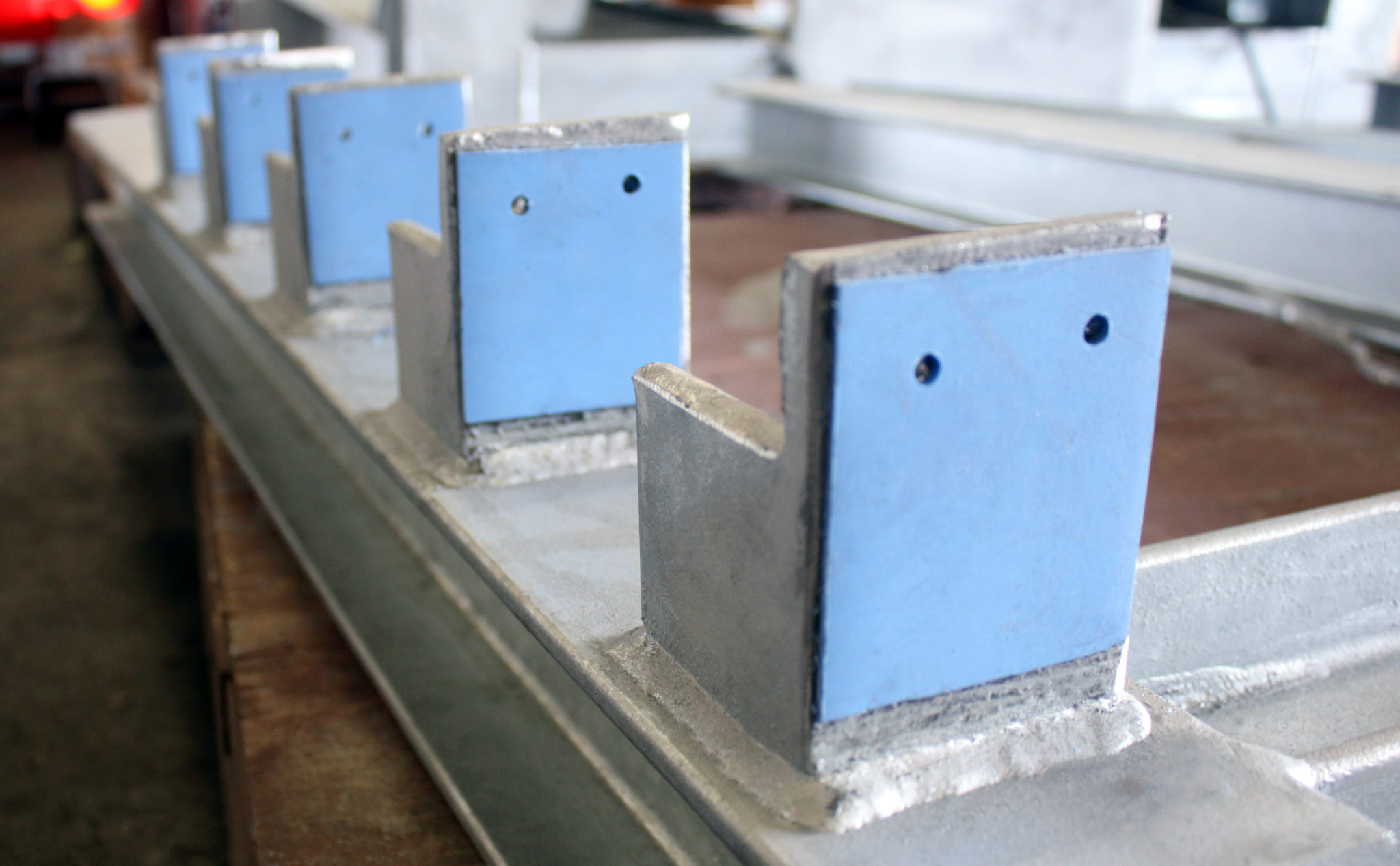

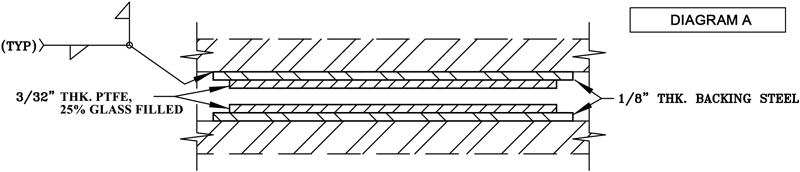

Prior to Welding: Locate the slide plate base in the appropriate position on the existing steel surface. Place a protective covering on the PTFE, 25% glass filled. Where seal welding is not required, follow the diagram shown which indicates 1/8” thick fillet weld, 1” long every 4” around the entire perimeter of the base. For welding, use GMAW 0.035 wire or SMAW 3/32″ stick.

Where full seal welding is required, use a similar pattern of welding until a full weld is obtained. This method will prevent damage to the PTFE, 25% glass filled. (A full weld will help prevent seepage of water between the slide bearing plate and the support structure.) Avoid overheating, which may destroy the bonding of the PTFE, 25% glass filled to the base plate.

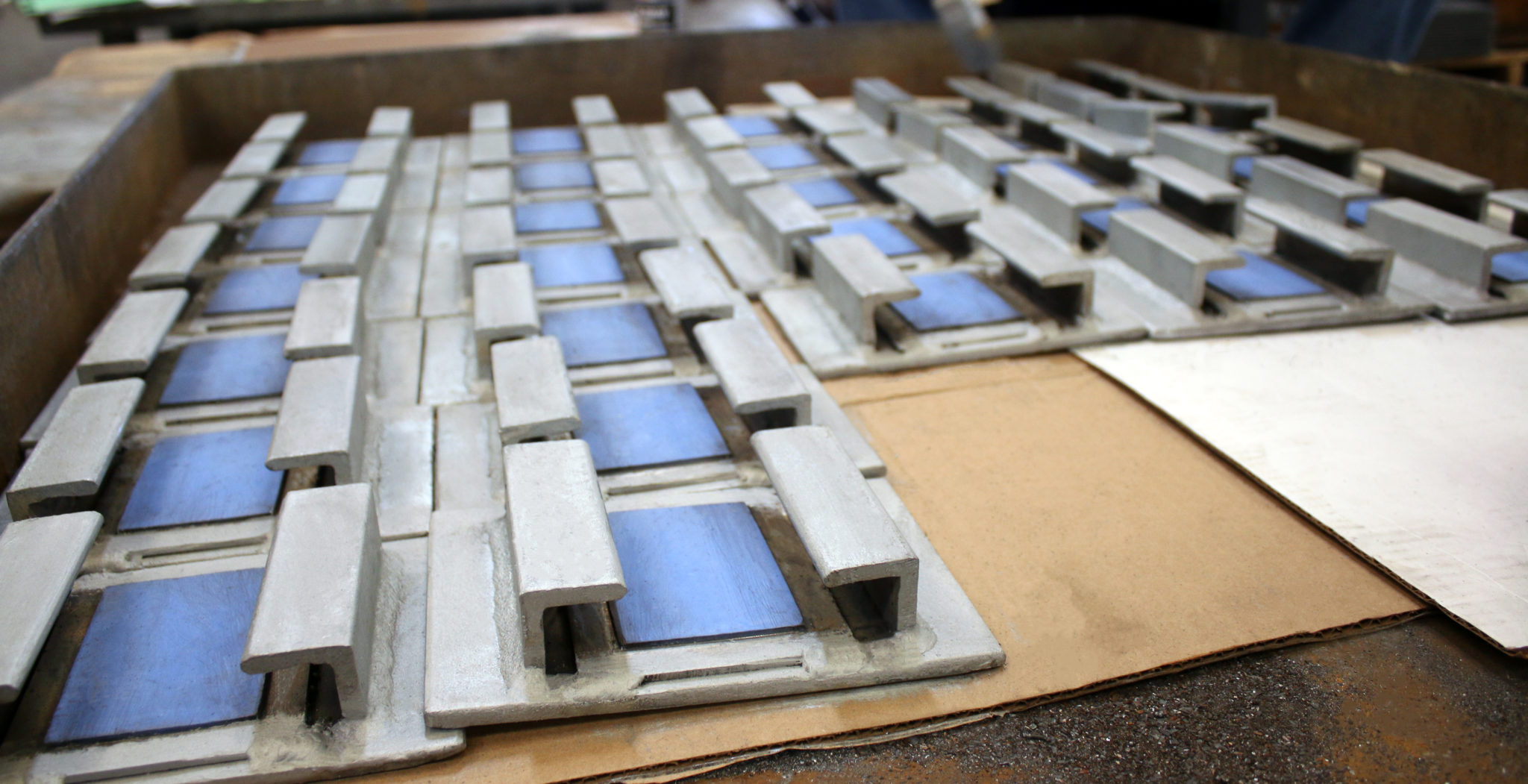

Installation in Concrete: When installing PTFE, 25% Glass Filled Slide Plate assemblies in concrete, anchor bolts will be integrated into the base plates for attachment to either the concrete form rebar structure or simply within the concrete itself.

Request a Quote