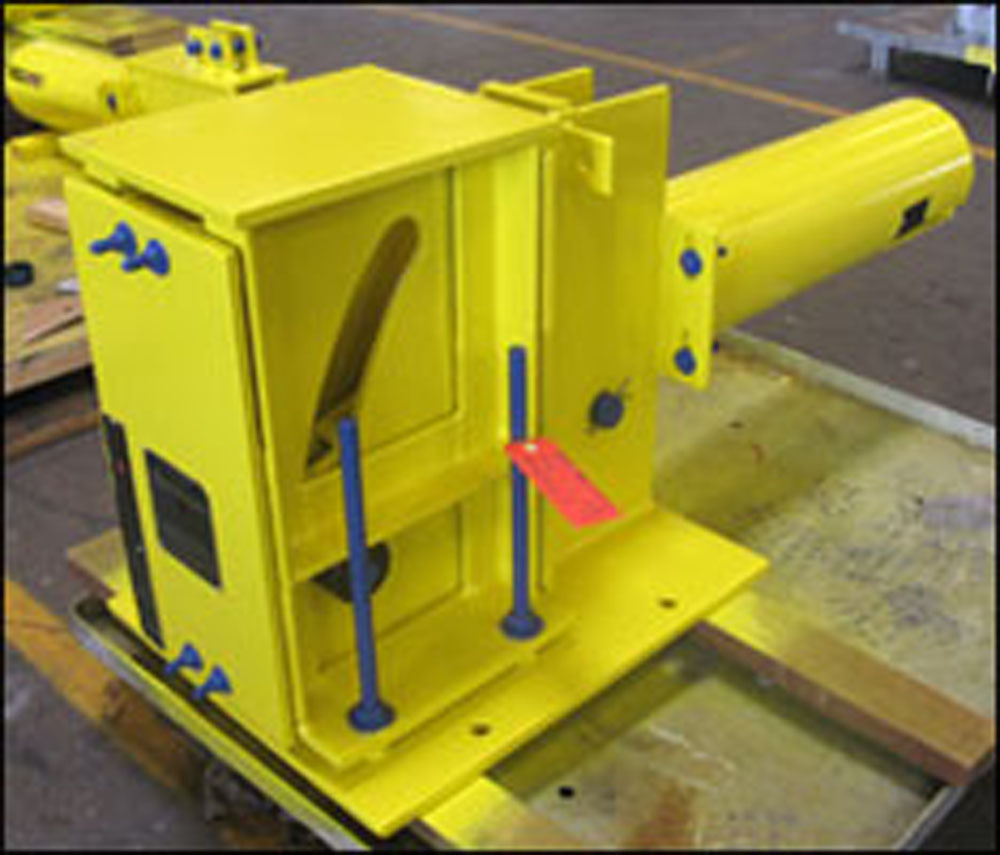

These PTP-1 F-Type variable spring assemblies fabricated from A-36 carbon steel, were custom designed to accommodate a height of 11-11/16″ while keeping the same spring rate. The F-Type variable is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The variables are designed for loads up to 6,500 lb. and a total upward travel of 5/16″.

Want to learn more about variable springs? Check out a recording of a past live webinar.