PT&P manufactured seventy-two bolt cradle pipe supports for a Sulphuric Acid Plant in Canada. The supports are designed for pipes ranging from 1-1/2″ to 20″ in diameter. They are fabricated from carbon steel and coated with a special protective paint for acid service. Standard bolt cradle supports are offered in 2″ to 24″ diameter pipe sizes; however, PT&P can manufacture any size needed for your application.

Resources

Resources

112 Custom Variable Springs Designed for a Furnace Application in Venezuela

112 custom variable springs designed for a furnace application for an oil refinery in Venezuela. The furnace cans are designed from carbon steel and painted with red oxide primer to prevent corrosion when exposed to high temperatures. The sizes of these figures PTP-6 and PTP-8 range in length from 25″- 39″, with a total travel of 0.1″- 1.821″ and loads varying from 430 – 681 lb. A load test to confirm the spring rate was conducted on each assembly prior to shipment.

Pipe Guides Designed for a Recovery Boiler

These pipe guides were designed for a recovery boiler in a power plant in Oklahoma. The guides were designed to control lateral pipe movement and maintain the alignment of the piping through its axial and contraction cycles. They were designed to support 6″, 12″ and 18″ pipes and range in length from 70″ – 120″. The assemblies were fabricated from carbon steel with a hot-dipped galvanized finish.

27 B-Type Variable Spring Supports Designed for an Oil Refinery

PT&P designed and manufactured 27 B-Type variable spring supports for an oil refinery in Louisiana. The spring cans, rods, welded beam attachments, turnbuckles and clevises are fabricated from carbon steel. The spring cans have a 12-3/4″ diameter and measure 290″ from the bottom of the steel to the connection of the pipe. They were designed for 2″ of vertical movement and operating loads between 24,375 and 27,500 lb.

215 Heavy Duty Pre-Insulated Pipe Supports Designed for a High Temperature Application

Pipe Shields Inc., a division of PT&P, manufactured 215 heavy duty pre-insulated supports for a high temperature application in Oregon. They are 15″ L x 20″ W x 31″ H and are designed to accommodate 14″ – 20″ diameter pipes. The hot shoes have a calcium silicate insulation thickness of 2.5″- 3″. The base, clamps, nuts, jackets and bolts are all fabricated from hot dipped galvanized carbon steel and coated with red oxide paint. Standard Q.C. and dimensional tests were performed prior shipment.

282 Instrument Supports Designed for a Six-Drum Coker Unit

PT&P designed and manufactured 282 instrument supports to support a six-drum Coker unit in a refinery in Indiana. Some of the assemblies are designed to be bolted by anchor bolts while others are designed to be welded. The supports are fabricated from hot-dipped galvanized carbon steel and measure 11″ – 61″ in height and 5″ – 28″ in width.

Sway Strut and Pipe Clamp Assemblies Designed for a Natural Gas Facility in Canada

PT&P designed sway strut and pipe clamp assemblies for a pipeline at a natural gas facility located in Canada. The sway struts are 87-1/2″ in length and the clamps are designed for pipes ranging from 6″ to 42″ in diameter. The assemblies are designed for operating loads ranging between 3,300 lb. to 20,000 lb., with an operating temperature of 392°F and 9mm -20mm of allocated vertical movement. A load test was performed on the assemblies prior to shipment.

42" Dia. Transition Piece Designed for a Water Tower in Texas

Sweco Fab, Inc. (a division of PT&P) custom designed a transition piece weighing 6,000 lb. for a facility in Texas. The piece measures 48″ x 72″ x 72″ and is fabricated from carbon steel. It will be used to connect a round water tower to a square duct. Prior to shipping, the product was 100% dye penetrant tested.

Variable Spring & Graphite Slide Plate Assemblies Custom Designed for Gasoline Production in Dubai

In eight weeks, PT&P provided a gasoline production plant in Dubai with two custom designed variable assemblies. Each assembly includes load columns, four variable spring cans, four channels, 12 plates, nine graphite slide plates and a custom designed frame. The frame allows the variable springs to work in unison to support large pipe trunnions. The top plates measure 45″ in width and 25″ in height. The variables are designed for an operating temperature of 750°F and an operating load of 3,150 lb. The assemblies are capable of 1/8″ upward movement and 1/6″ downward movement. A load test was conducted prior to shipment.

112 Variable Spring Supports for a Furnace Application

PT&P designed and fabricated 112 variable spring supports for a furnace application at an oil refinery in California. The spring cans are fabricated from carbon steel, vary from 36″ to 54″ in height and designed to operate at 400°F. The furnace cans are designed for operating loads ranging from 180 lb. to 1,400 lb. and movements from 1″ to 5″. The customer specified a custom paint system of two part iron oxide blue finish for the cans to comply with refinery conditions. Load tests were performed on the assemblies prior to shipment to determine the operating load and variability.

81 Pipe Shoes Designed for a Solar Power Plant in California

PT&P designed and manufactured eighty one custom pipe shoes for a solar power plant in California. The shoes will support heat transfer in fluid pipes at the facility. They consist of 3/8″ stainless steel slide plates and microtherm insulation. The shoes measure 10″ wide, 10″ height, and 18″ in length with a 750°F operating temperature. The assemblies have a vertical operating load of 10,000 lb. with 2″- 3″ of axial movement.

100-B Type Constant Spring Supports Designed with Double Transverse Lugs for a Refinery in Mexico

These 100-B Type vertical constant spring supports were designed with double transverse lugs for a refinery in Mexico. The constants were fabricated from A-36 carbon steel and they range in size from 23-1/4″ to 26-5/8″ in height, 50″ to 78″ in length and 18-3/8″ to 18-3/4″ in width. They are designed for operating loads ranging from 8,000 – 27,000 lb. and upward movements ranging from 3″ to 7″. The double transverse lugs allow the entire constant to swivel with the rod. Standard load and travel tests were performed prior to shipment.

For an export gas pipeline, would you combine the pig launcher and receiver or separate them?

This decision would be made by a pigging services company during the design process. Technical data and financial impacts would have to be analyzed prior to choosing whether or not a pig launcher and receiver should be combined. We fabricate the products according to the specifications provided to us after the analysis is complete.

(512 psig at 100°F)

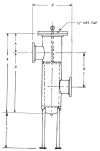

Do you design the davit or is it designed from another vendor?

We design the davits and have developed a standard design for ones that are generally 12”-24” in size. We design each davit per requirement for sizes above 24”.

Elevation with blind flange. Davit Assembly

(optional)

Do you only use ASME Codes to evaluate pressure vessels or do you also use other standards such as CODNAP and AD Merkblatter for reduction in thickness of vessels?

Normally, we only use ASME Codes to evaluate reduction of thickness in pressure vessels.

Why is there a major and minor barrel in a pig launcher and receiver?

A major barrel is bigger than the normal piping in the system to make it easier to insert the pig and launch and receive it. The minor barrel has the same inside diameter as the main pipeline and is used to clean the pipes.

( 675 psig at 200°F)

How do you define a hydro-test pressure based on design pressure?

Hydro-test pressureand holding times vary for different design codes. For example, the ASME SEC VIII Div.1 general hydro-test pressure will be1.3 x design pressure (minor factors may vary for this equation as well) and forpiping design codes, the hydro-test pressure will be ASME B31.4,B31.8 1.5 xdesign pressure.

What is a davit?

A davit (particularlyfor manways) is a mechanically designed hinged guide and support system thathelps ease the opening and closing of large and heavy blind flanges. Thisassembly can be designed for horizontal and vertical applications.

What is a spectacle blind?

A spectacle blindconsists of a blind and spacer. The blind is installed in between flanges tosecurely shutdown pipeline during leakage or maintenance. When a blind is notrequired, a spacer can be installed in between flanges to continue regularoperating conditions.

What is a flow rate?

The flow rate is theamount of liquid passing through a particular area over a period of time. It isgenerally measured in gallons per a minute or cubic feet per meter.