PT&P engineered spring supports are broken up into four main categories. Click on the pictures or titles below to view a list of featured projects in that category.

|

|

|

|

Variable Spring Supports |

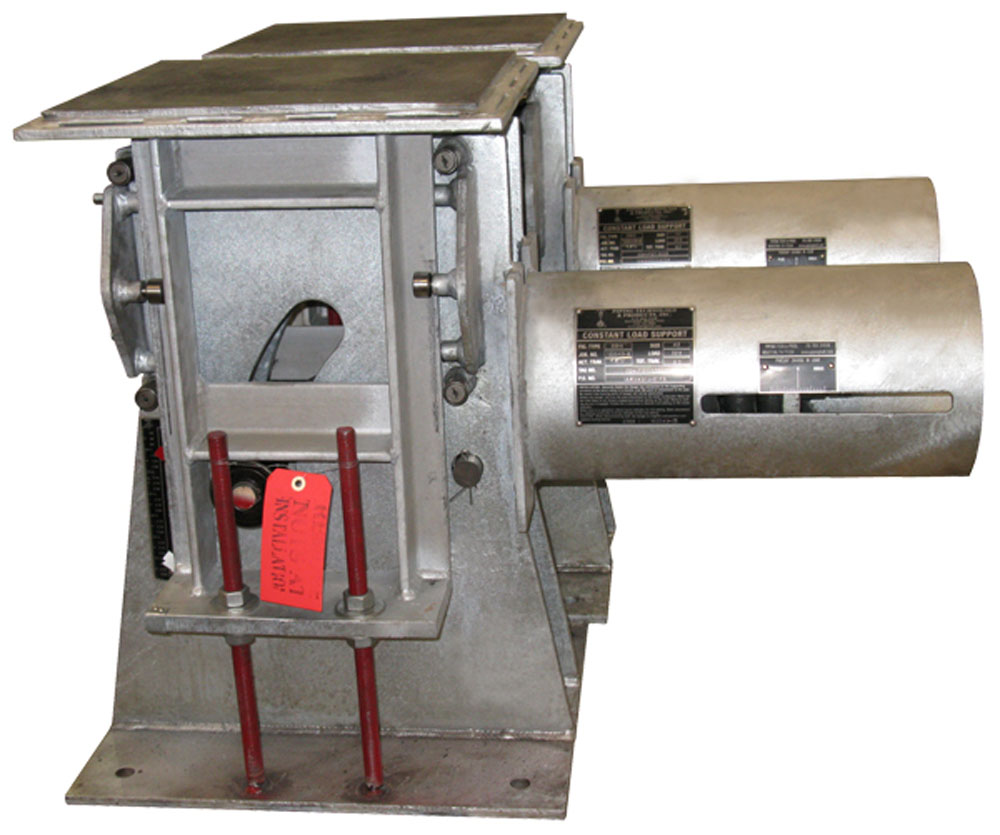

Constant Spring Supports |

Big Ton Spring Supports |

Compact Spring Supports |

PT&P designs and fabricates a variety of engineered spring supports. The main purpose of spring supports is two-fold: 1.) To uphold a specific load, including the weight of the pipe, commodity, flanges valves, refractory, insulation, etc. and 2.) To allow the supported load to travel through a predetermined thermal deflection cycle from its installed condition to its operational condition.

Variable Spring Supports use coiled springs to support a load and allow movement. The resistance of the coil to load changes during compression, which is why these devices are called “variables”. We offer a variety of different designs of variable spring pipe supports. The way a variable spring support responds to an applied load depends on the coil or coils inside the casing. Each coil arrangement has a spring rate expressed in units of pounds/inch (or kilograms/millimeters) of compression. The required coil size is determined by load while the required number of coils (length) is determined by the anticipated range of movement. A longer coil or coils placed in series will provide greater travel for similar loads. Manufacturers use their figure numbers to designate the coil arrangements which provide greater movement.

Constant Spring Supports use a spring coil (or series of coils) to accommodate pipe movement from the initial (installed) condition to the final (operating) condition of the piping system. For all constant spring supports there is no difference in load and the supported load will remain uniform throughout the deflection cycle. Both constant support styles, style 100 (with a vertical coil housing orientation), style 200 (with a horizontal coil housing orientation), function in the same manner. The key to selecting a constant support style would be the space available for that support above, below and around the piping. The next step would be to select a support type. Types that support piping from above would be types (A, B, C, D, E, and G). Types that support piping from below would be types (F and U).

Big Ton Spring Supports are designed primarily for the petrochemical industry where two important characteristics in spring supports are necessary:

- Stability: Big Ton spring supports are extremely stable. Base support springs of this design are frequently used under horizontal pressure vessel saddle supports in combination with slide plates or roller supports. This design is sufficient where there is a minimal amount of lateral movement, but where the combination of heavy loads and thermal expansion are required, Big Ton industrial springs should be your choice.

- Heavy Loads: The load values can be modified to accommodate the client’s needs. Loads up to 200,000 lb. can be handled with no problems.

Compact Spring Supports (also known as Disc Springs) are beneficial at minimizing excessive loads on sensitive equipment, applications with limited space and are ideal for locating under equipment flanges & reduces design time, maintenance cost and accidents. PT&P partnered with Disc Spring Technology (DST) and is now manufacturing the compact spring support. The compact spring supports are based on the use of custom-engineered conical (Belleville) springs, which allows PT&P/DST to offer a full range of patented spring supports that suite the need for large loads and small movements.