Products

Product information pages.

Insulated Supports (Figures 4500 – 4800)

Insulated pipe supports are designed to prevent direct heat transfer between pipes and their supports. Thus, they reduce heat loss due to conduction at each support. They serve the following purposes: Carry the load and allow necessary movement at each suppose point, provide insulation in the support area where the regular pipe insulation cannot be installed and minimize the cost of field installation by reducing installation time. The supports are not welded to the pipe and each unit is shipped completely assembled (except for the riser supports and anchor supports, both of which require some welding).

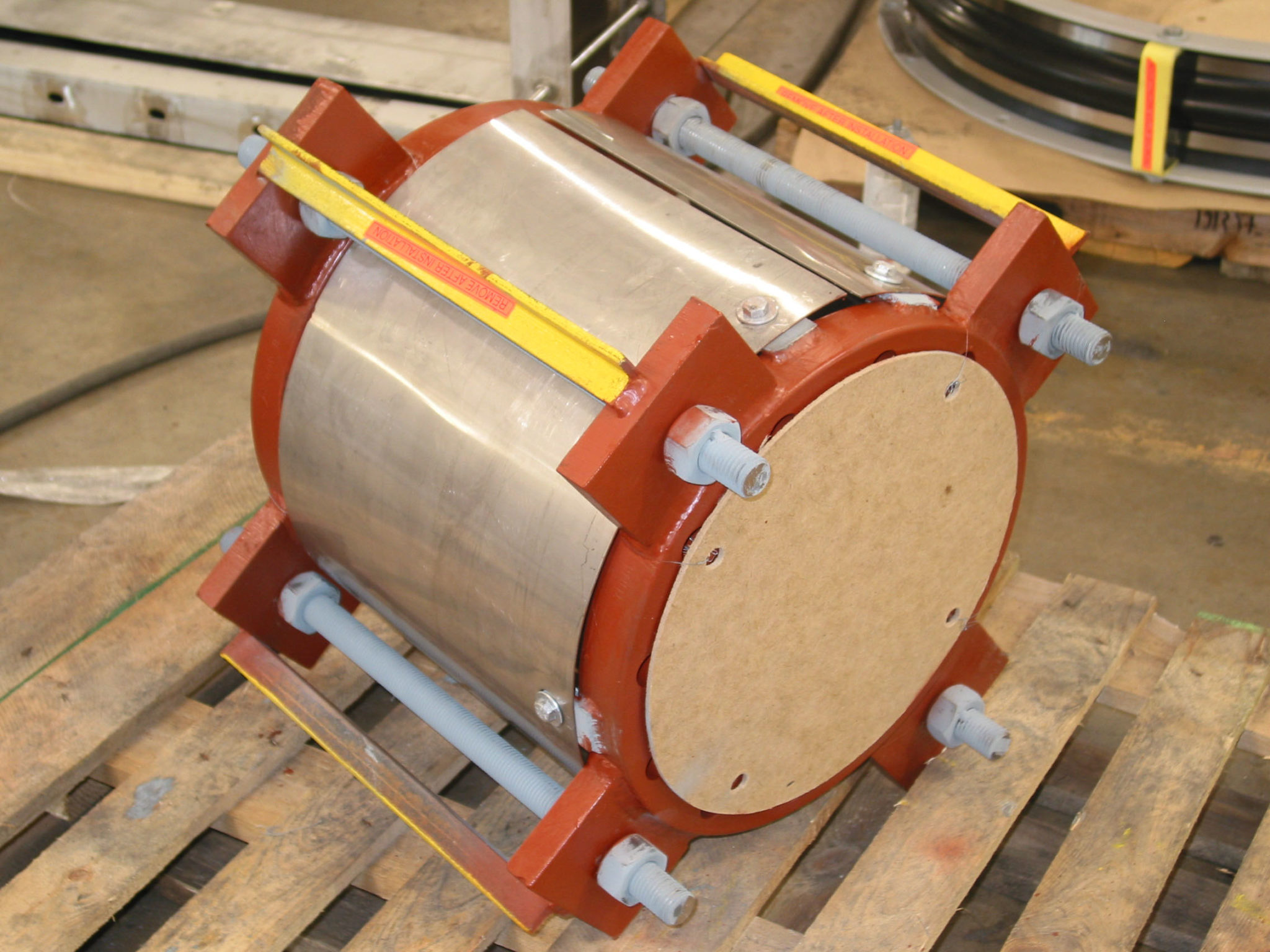

Single Expansion Joint

Single expansion joints are the most common and simple type of expansion joint designed and manufactured by U.S. Bellows, Inc., a division of PT&P. This type of expansion joint is a single bellows element with end connections known as flanges and ranges in size and materials. Our standard bellows range from 3” to 156” in diameter; however, we can provide any diameter your application specifies. Single expansion joints will deflect the movement in any direction or plane the bellows element allows. This style of bellows will not resist deflections except for the resistance of the bellows and requires the piping to be restrained or controlled by main/directional anchors.

U.S. Bellows has been providing expansion joints since the 1960s and was acquired by PT&P in 1997. PT&P is uniquely positioned to service expansion joints as we are the only bellows manufacturer globally with deep pipe stress engineering expertise who manufactures expansion joints and engineered pipe supports. With our unique engineering expertise in expansion joints, pipe stress, and engineered pipe supports, PT&P/US Bellows has developed hundreds of custom designs for unique customer requirements. Lastly, PT&P/U.S. Bellows is one of only 14 global members of the Expansion Joint Manufacturer’s Association, which sets the standards for expansion joint engineering.

Choosing an experienced bellows manufacturer will reduce your plant shutdowns and service outages, along with simplifying at least one part of your overall project.

More About Single Expansion JointsView Product Page

Pressure Vessels & Tanks

Sweco Fab has been fabricating various types of pressure vessels for the past 25 years in accordance with ASME Sec. VIII, Div 1 (2021 edition). We also fabricate welded steel tanks per API 650, API 12F codes & custom design tanks. Sweco Fab had fabricated vessels that fulfilled specifically to each customer’s requirements and will continue doing so in the future.

Sweco Fab can fabricate pressure vessels made out of Carbon Steel (including Low Temp CS A350 LF2), Stainless Steel (304/L or 316/L) and Cr-Mo Grade 5 (A387 Grade 5). The sizes ranges from 6″ OD to 110″ OD with vessel thickness up to 2″ thick. Our shop can accommodate vessel weights up to 40,000 lbs (20 tons) max.

We have certified welders, pipe-fitters and QC inspectors plus credible subcontractors to satisfy NDE requirements (X-ray, Dye Pen, PMI, Hardness and PWHT) per project specifications. Yearly training and refreshers are conducted in accordance to ISO 9001 Standard.

Sweco Fab has currently both ASME “U” Stamp and “R” Stamp authorized by the National Board of Boiler and Pressure Vessel Inspectors.

48” OD X 120” LG. Lube oil storage tanks were fabricated out of all stainless steel for the chemical company. Storage tanks were designed for atmospheric pressure & temperature. All tanks were supplied with saddle structural support & ladder for inlet access on Top. Fabricated Oil storage tanks were supplied with 300 gallon, 500 gallon and 1000 gallon capacity.

More About Pressure Vessels & TanksView Product Page

Variable Spring Supports

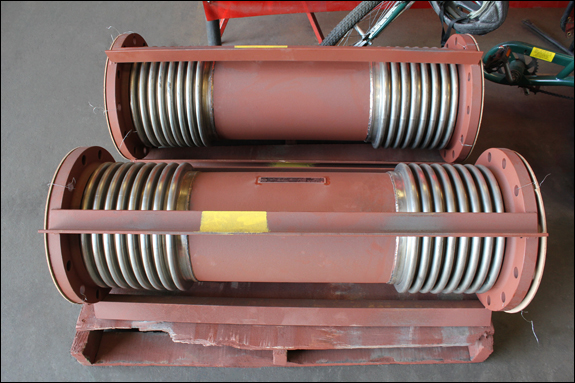

Universal Expansion Joint

The main purpose of the universal expansion joint is to accommodate lateral movements that a single expansion joint cannot handle. The universal expansion joint consists of two bellows separated by a pipe spool section. The ability to accept lateral deflection depends on the angle that each bellow can absorb. The additional increase or decrease of the lateral deflection is influenced by the distance between the bellows so by changing the length of the pipe spool, the spring rate of the universal expansion joint can be affected.

The advantage of the universal expansion joint’s construction is its ability to absorb any different types of displacement: axial, lateral, and angular, as well as their combination. Lateral and angular movement of the pipe system can be limited by tie rods, which at the same time balance the pressure thrust in this part of the piping system. For these types of joints designed for only lateral movement, the overall length of the unit does not change when the pipeline is heated. This solution successfully solves the problem of thermal expansion of pipelines. You can find more details about the maximum temperature and number of cycles that standard universal expansion joints can withstand on the page about this product.

Piping Tech & Product Inc. / U.S.Bellows is a PT&P subsidiary company. This experienced manufacturer, with the tradition of making expansion joints, stretches back to the middle of the last century. In addition, PT&P has a long tradition of designing, manufacturing, and servicing expansion joints and pipe supports. Besides standard products, PT&P and U.S. Bellows design and develop these devices for customers with special requirements. PT&P / U.S. Bellows actively participate in the work of the Association of Manufacturers of Expansion Joints, which sets standards for the engineering of expansion joints.

Information on expansion joints and the design life of these units can be found on the Cyclic Deflection and Cycle Life page on the US Bellows website.

More About Universal Expansion JointsView Product Page

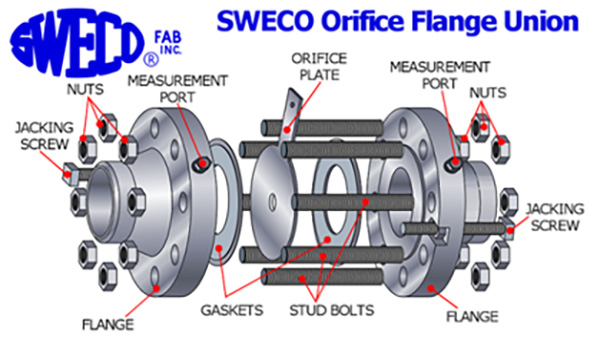

Orifice Plates & Flanges

Sweco Fab supplies orifice plates (with concentric, eccentric, or segmental bore) in Stainless Steel or other Nickel alloys, Monel 400, Alloy 20, Inconel 600, 625 and 718, Hastelloy C276 & B-2, Titanium Gr.2. The shape and manufacturing tolerances of plates used in measurement applications are defined in the international standardization publications of ISO, AGA, ASME, and others.

SWECO® Paddle Style Orifice Plates (OP) are designed to fit between two specially modified flanges inside what is called an Orifice Flange Union (OFU). Orifice plates within OFUs are designed to create a restriction which causes the pressure of the fluid flowing through the pipe to drop. The drop in pressure varies directly with the flow of the fluid within the system. Virtually any bore shape or configuration can be used to measure flow in a pipe, but the most common is a concentric (center) bore with a round hole having square, conical, or quadrant (radius) bore wall. Bore Calculations are available upon request.

The Orifice Flange Union will consist of the following parts:

- Two special flanges facing each other (modified with jacking screws and ports)

- Two gaskets

- Studs and bolts

- SWECO ® Orifice Plate

- Additionally, some OFUs have dowel pins to improve accuracy of alignment.

It is common for the OFU to have flanges with a material consistent with the pipeline and an Orifice Plate of stainless steel.

Constant Spring Supports

Pipe Shields Pre-Insulated Pipe Supports (A1000 – G3000)

For more than 40 years Pipe Shields Inc. and PT&P have reached throughout world markets to design and develop for power, petrochemical, chemical, and commercial industries. The accomplishments of our high-quality products are a direct result of years of research and engineering to create cost-efficient products. Pipe Shields insulated supports incorporate materials strong enough to carry the load while insulating the pipe at the same time. These supports were designed because fiberglass and foam glass materials were not strong enough to carry the load at the point of support without crushing.

Pipe Shields developed a variety of insulated pipe supports for a number of different industries designed specifically to carry the load, limit the amount of welding required, and prevent metal to metal contact.

Commercial and Light Load Applications (A Models)

Models A group are widely used in commercial applications and for smaller loads and movements, like chilled and heated water systems. That makes this model group popular among mechanical contractors.

- Commercial and Light Industrial Pre-Insulated Pipe Supports (A1000 thru A9000)

Heavy Industrial Applications (B and C Models)

Model – B group was built to support larger loads (vertical and lateral) and movements. Some models support the pipe from below. Commonly used in heavy industrial and large HVAC distribution system

- Base Mounted Pre-Insulated Pipe Supports (B1000 thru B8300)

Model – C group was built to support larger vertical loads while limited movement in the lateral and axial directions. These are commonly called Pipe Anchors.

- Pipe Anchors (C1000 thru C4300)

Pipe Riser Clamps Applications (D, E and G)

- Hanger Type Pre-Insulated Pipe Supports (D1000 thru D6300)

- Insulated Pipe Riser Clamps (E1000 thru E2300)

- Pipe Clamps, Pipe Guide Straps, Pipe Guide U-Bolts (G1000 thru G3000)

More About Pipe Shields Pre-Insulated Pipe SupportsView Product Page

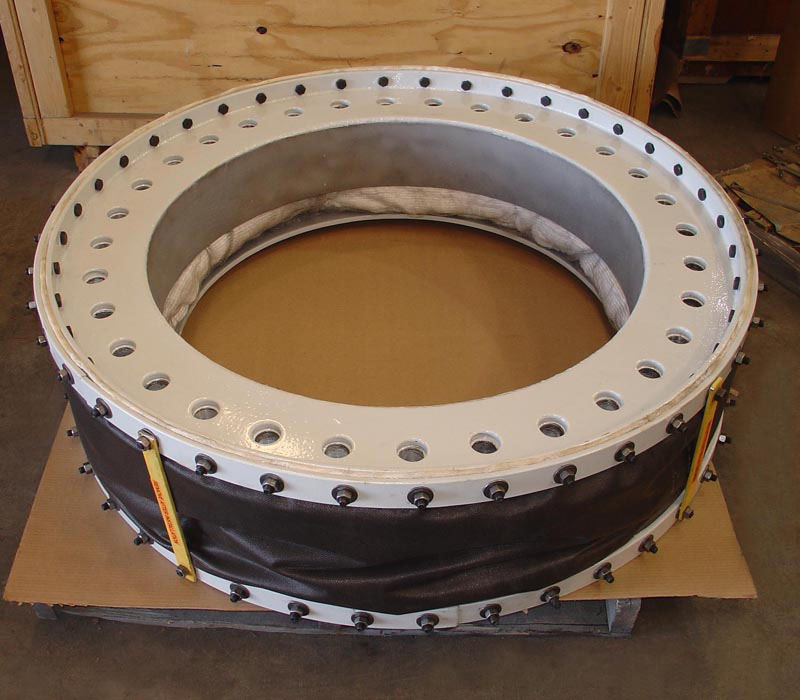

Fabric Expansion Joint

Fabric expansion joints are often used in ductwork to transfer hot gases under low pressures. These expansion joints normally consist of fabric belting material and a metal frame. Combining different insulation layers, which are made of different fabrics, help the fabric belt and insulation layers to adapt to the temperatures and pressure in the system. Insulation pillows, accumulation barriers or flow liners are used to protect the fabric belt in cases where the fabric material needs to be additionally protected. The fabric expansion joint frame connection with channel ends can be welded or bolted to the duct ends.

For example, take ductwork for the transfer of hot, low-pressure media in power plants. In this kind of large combustion process, we have “flow of air” and “exit gas”. In this kind of large combustion process, we have “flow of air” and “exit gas”. In such ducting systems, expansion joints made of fabric can perform a double function. To compensate for thermal growth of the duct and compensate for minimum duct misalignments on expansion joint connection points.

This type of expansion joint can be inserted into the parts of the ductwork where movement occurs. The advantage compared to metal expansion joints is reflected in the absorption of larger movements and the absence of spring loads that could be transferred to other parts of the ductwork. By reducing the thermally induced stresses in the ducting, other elements of the ductwork, such as supports and related equipment, will be exposed to lower stresses.

U.S. Bellows, manufacturing tradition stretches back to half of the last century. The team of engineers at PT&P / U.S. Bellows has extensive experience in assessing operating conditions and designing expansion joints. The types of frames manufactured at U.S. Bellows have features designed to reduce the adverse effects caused by pressure, temperature and turbulence of various media. Fabric expansion joints, designed this way, have a long service life.

The fabric belt deforms depending on the movement of the duct. The fabric must perform its main task without tearing. The fabric is sometimes exposed to high temperatures and/or corrosive media, so it may need to be changed periodically.

More About Fabric Expansion Joints View Product Page

Pig Launchers & Receivers

Pig Launchers and Receivers are installed in pipelines to launch and receive Pipeline Pigs. Pigs can be used for the cleaning of pipelines. In addition, Pigs can be used for the separation of two products within the same pipeline. Sweco Fab has over 40 years of experience in designing and manufacturing a wide variety of ASME/Misc. Fabricated Products – including Pig Launchers and Receivers.

Sweco Fab fabricates these pig launchers and receivers per ASME Code B31.4 and B31.8.Major and minor barrels can be supplied both in Carbon Steel and Stainless Steel, including API 5L X42 to X65 pipes. Barrel sizes range from 4” x 6” 150# rating up to 48” x 54” 900# rating. NDE (Non-destructive exams) like X-ray, Dye Pen aka Liquid penetrant test, PWHT, Hardness test, PMI and Hydro-test with chart recorders are performed prior to shipment.

More About Pig Launchers and ReceiversView Product Page

Big Ton Spring Supports

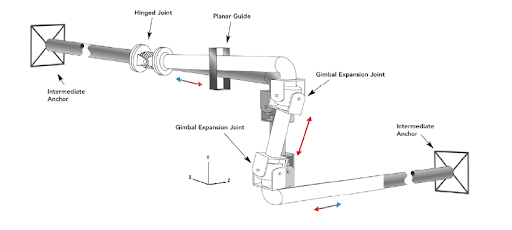

Hinged Expansion Joint

One of the critical benefits of hinged expansion joints is their ability to absorb and compensate for expansion and contraction in pipelines when used in sets of two or three. Without these expansion joints, the pipeline would be subject to higher stress, which could result in cracks or ruptures in the pipeline. Hinged expansion joints reduce stress in the pipeline sections allowing the pipeline to expand and contract freely.

Another benefit of hinged expansion joints can be their ability to absorb and dampen vibration in the pipeline. Metal bellows can be used in applications where the vibration is of high frequency and low amplitude, otherwise, it may be detrimental to the function of the bellows. Vibration can occur for various reasons, such as from the flow of materials, pressure fluctuations, or equipment operating nearby. Without a hinged expansion joint, the pipeline would be subject to excessive vibration, which could cause damage to the pipeline or equipment. The hinged expansion joint dampens these vibrations and prevents damage from occurring. US Bellows can help you decide if a Hinged expansion joint is a suitable solution to your vibration problem.

More About Hinged Expansion JointsView Product Page

The hinge mechanism in a hinged expansion joint allows for angular movement in the pipeline while containing the full pressure thrust, which is especially important in applications where the pipeline needs to change direction. The hinge allows the pipeline to bend and flex while maintaining a continuous flow of materials. This feature is particularly useful in applications where space is limited or where the pipeline needs to navigate around obstacles.

One of the key considerations when selecting a hinged expansion joint is the material of construction. The material used for the bellows and hinge must be compatible with the materials being transported in the pipeline, as well as the temperature and pressure conditions. Common materials used for the bellows of hinged expansion joints include stainless steel, Inconel, and Monel. Each material has its own unique properties and advantages, and the selection will depend on the specific application.

Installation of a hinged expansion joint is also crucial for ensuring its proper performance. The joint should be installed in a manner that allows for unrestricted movement, without any interference from nearby equipment or structures. The pipeline should be properly supported to prevent any sagging or stress on the expansion joint.

U.S. Bellows became a part of PT&P in 1997. PT&P has an exclusive advantage in providing expansion joints because it is the only global bellows manufacturer with profound proficiency in pipe stress engineering and manufacture of expansion joints and engineered pipe supports. Due to PT&P/US Bellows’ unparalleled knowledge in pipe stress, expansion joints, and engineered pipe supports, they have developed numerous custom designs to meet individual customer needs. Moreover, PT&P/U.S. Bellows is one of the 14 global members of the Expansion Joint Manufacturer’s Association, which determines the benchmarks for expansion joint engineering.

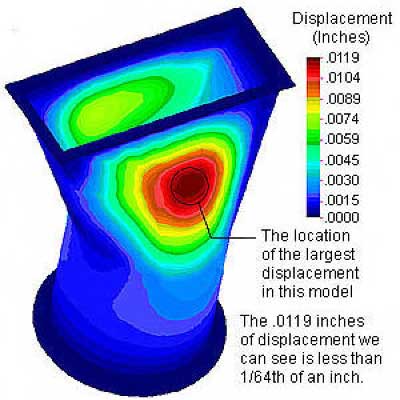

Transition Pieces / Ductwork

Ductwork encompasses a number of control devices (such as longitudinal duct, elbows, dampers, concentric reducers, eccentric reducers, expansion joints and support systems) that either deliver or carry air, exhaust gases, vapors, fumes, smoke, and/or particulate matter in a number of ventilation applications. Within this realm, U.S. Bellows and Sweco, offer custom-designed expansion joints and fabricated ductwork assemblies. These assemblies, which can encompass fabricated elbows, tees, and straight ductwork sections, are available in carbon steel or stainless steel, with diameters of 42″ or larger. The flexibility of these duct sections is enhanced with the inclusion of fabric or metallic expansion joints, catering to both rectangular and round configurations. U.S. Bellows and PT&P extend their expertise to specialized pipe supports, spring hangers designed for large-diameter ductwork, and comprehensive pipe stress analysis through CAESAR II software.

Key Features of U.S. Bellows and Sweco Ductwork and Transition Pieces:

- Material Composition: Primarily crafted from stainless steel or carbon steel.

- Expansion Joint Options: Inclusive of fabric or metallic expansion joints.

- Configurations: Available in both round and rectangular shapes.

More About Ductwork and Transition PiecesView Product Page

The air within process ductwork may operate under ambient conditions or reach temperatures of up to 900 °F (482 °C). These ducts exhibit a wide range in size, spanning from 2 ft diameter to 20 ft diameter or rectangular configurations measuring up to 20 ft by 40 ft. Notably, larger process ducts may accumulate dust, weighing 2 to 4 tons per linear foot based on the slope.

In the realm of structural process ductwork, considerations extend to industries such as cement, lime, and lead. Rectangular ductwork falls under the purview of the ASCE’s guidelines for “The Structural Design of Air & Gas Ducts for Process Power Stations and Industrial Applications.”

The longevity and effectiveness of ductwork rely significantly on the materials used in its construction. In challenging industrial settings, galvanized steel, renowned for its durability, is applied, whereas aluminum, prized for its lightweight properties, provides an apt solution for commercial environments. US Bellows underscores its dedication to excellence by highlighting the synergy of precision engineering and top-tier materials, resulting in the production of durable and resilient ductwork.

Compact Spring Supports

Gimbal Expansion Joint

When it comes to piping systems, expansion joints play a critical role in their performance and longevity. One type of expansion joint that is commonly used is the gimbal expansion joint. It is a flexible piping element designed to absorb and relieve movement, vibration, and expansion in pipelines. The gimbal expansion joint is often used in applications where the pipeline needs to change direction or navigate around obstacles or where space is limited.

A key advantage of gimbal expansion joints is their ability to absorb and offset the effects of expansion and contraction in pipelines when used in sets of two or three. As materials flow through a pipeline, they undergo temperature, pressure, and flow changes that can create stress and potentially cause pipeline damage such as cracks or ruptures. The gimbal expansion joint mitigates this risk by enabling the pipeline to expand and contract freely without encountering excess stress.

More About Gimbal Expansion JointsView Product Page

Another common issue in piping systems is vibration, which can arise from the flow of materials, pressure fluctuations, or nearby equipment activity. If not properly managed, this vibration can harm both the pipeline and associated equipment. Gimbal expansion joints may effectively dampen these vibrations to prevent damage.US Bellows can help you decide if a Gimbal expansion joint is a suitable solution to your vibration problem.

The gimbal mechanism in a gimbal expansion joint allows for angular movement in two directions, while containing the full pressure thrust, which is especially important in applications where the pipeline needs to change direction or where there is a high degree of movement. The gimbal mechanism allows the pipeline to move freely, without experiencing any stress, which helps to maintain the integrity of the pipeline.

Choosing the appropriate construction material is a vital factor to consider when selecting a gimbal expansion joint. It is imperative to ensure that the materials used for both the bellows and gimbal are compatible with the materials being transported, as well as the temperature and pressure conditions. Commonly used materials for the bellows of gimbal expansion joints include stainless steel, Inconel, and Monel, each offering unique advantages and properties. The selection of the material will depend on the specific application requirements.

Since the 1960s, U.S. Bellows has supplied expansion joints and was acquired by PT&P in 1997. PT&P has a distinctive position in the expansion joint service industry, being the sole global bellows manufacturer with extensive expertise in pipe stress engineering and production of both expansion joints and engineered pipe supports. This engineering proficiency in expansion joints, pipe stress, and engineered pipe supports has enabled PT&P/US Bellows to create numerous custom designs for individual customer specifications. Furthermore, PT&P/U.S. Bellows is a member of the Expansion Joint Manufacturer’s Association, which is responsible for setting expansion joint engineering standards, along with only 13 other global members.

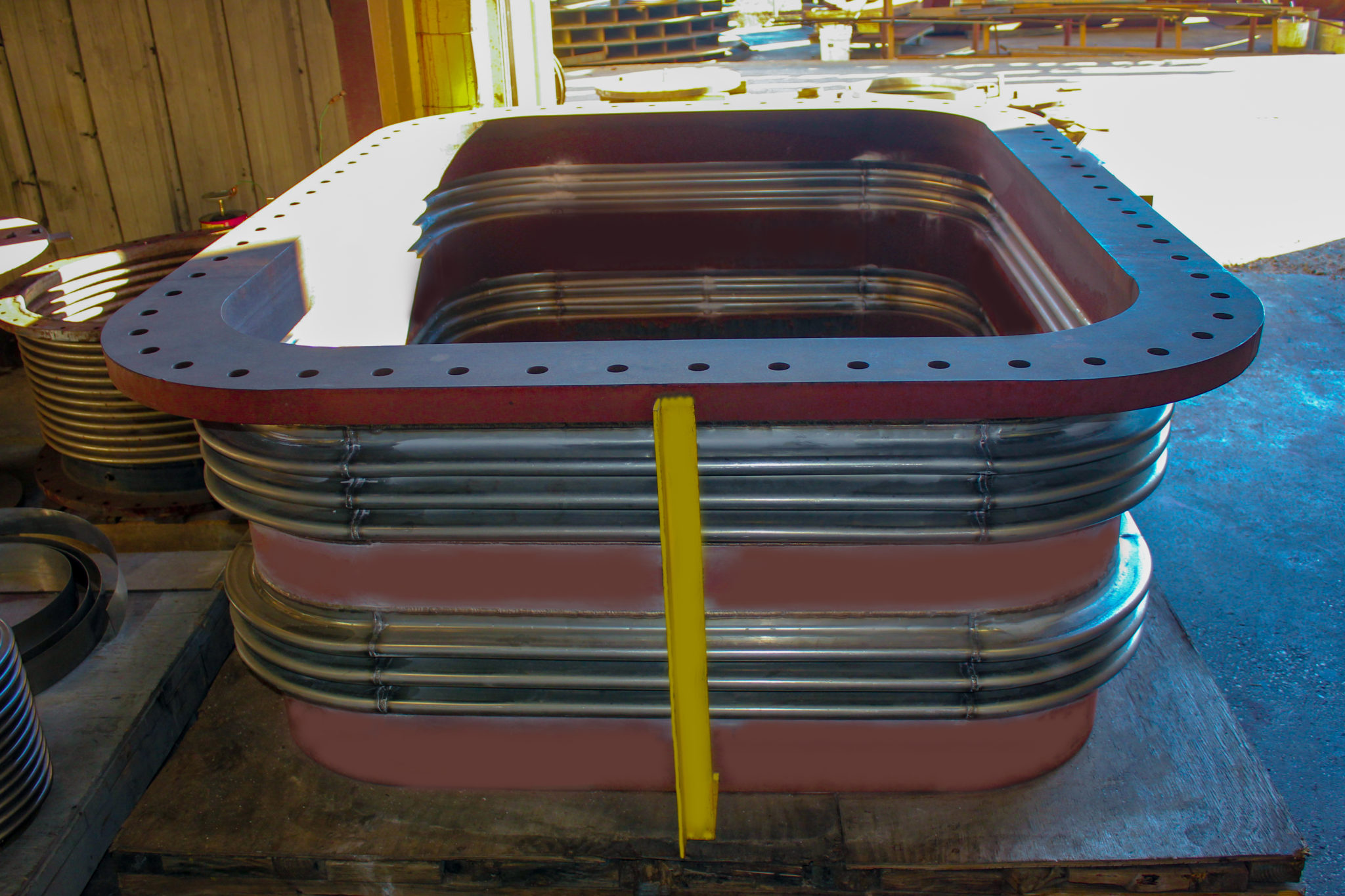

Rectangular Metal Expansion Joints

Rectangular metal expansion joints are flexible devices specifically designed to absorb the movement resulting from thermal expansion and contraction in duct systems. The bellows are typically constructed using durable metals like stainless steel, which provide the necessary strength and reliability in demanding operating conditions.

Rectangular metal expansion joints can be easily recognized by their distinctive shape. This shape sets them apart from other types of expansion joints, such as round metal expansion joints. The rectangular design enables these joints to accommodate movements in two perpendicular directions, making them ideal for applications with limited space or structural constraints.

When a duct system experiences temperature fluctuations, the pipes expand or contract accordingly. Without expansion joints, this thermal movement can subject the system to harmful stresses, potentially leading to fatigue failure or ruptures in duct systems.

Rectangular metal expansion joints are strategically installed in the ducting system at specific locations where movement is expected. These joints are designed with a series of convolutions or corrugations, imparting the necessary flexibility to the structure. When the pipes expand or contract, the corrugations in the expansion joint compress or extend, effectively absorbing the movement and relieving stress on the system.

More About Rectangular Metal Expansion JointsView Product Page

Rectangular metal expansion joints offer numerous benefits in duct systems. These joints provide flexibility, allowing for a greater range of movement compared to rigid connections. This flexibility helps reduce overall stress on the system, prolonging its lifespan and minimizing the risk of costly repairs or replacements. Rectangular metal expansion joints can act as effective vibration isolators. They can be designed to absorb and dampen vibrations caused by fluid flow, equipment operation, or external forces, preventing these vibrations from propagating throughout the system. This feature contributes to improved system performance, enhanced equipment reliability, and increased safety.

Rectangular metal expansion joints find applications across various industries where ducting systems experience thermal movements. Power generation plants, petrochemical facilities, HVAC systems, and industrial processing plants are just a few examples.

In power generation plants, rectangular metal expansion joints are used in steam and gas turbine systems, where they accommodate the thermal expansion of the equipment at vacuum conditions. They also play a vital role in flue gas desulfurization systems, compensating for movement resulting from temperature changes and equipment operation.

In the petrochemical industry, these expansion joints are utilized in duct systems that transport corrosive fluids or gases. They can be designed to withstand high temperatures, pressures, and aggressive media which makes them indispensable in this sector.

Rectangular metal expansion joints are indispensable components in ducting systems, offering flexibility and vibration isolation. With their wide range of applications in diverse industries, these expansion joints continue to play a vital role in maintaining the safety, efficiency, and reliability of various industrial processes.

To learn more about rectangular metal expansion joints and their applications, click on the appropriate button to find more information about these products. US Bellows website provides detailed information and resources to enhance your understanding of this subject matter.

Bellmouth Reducers

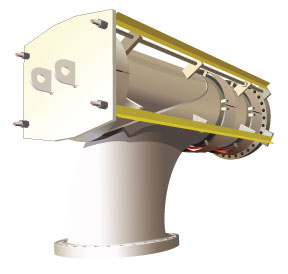

Elbow Pressure Balanced Expansion Joints

When it comes to ensuring the smooth operation of piping systems in various industrial applications, expansion joints play a pivotal role in accommodating thermal movements, vibrations, and misalignments. The Elbow Pressure Balanced Expansion Joint stands out as a remarkable engineering solution among the different types of expansion joints.

Elbow Pressure Balanced Expansion Joints, also known as elbow pressure compensators, are flexible components specially designed to absorb axial and lateral movements in piping systems while containing pressure thrust. They are often utilized in pipelines where space constraints or specific layout requirements demand a bend or an elbow configuration. These expansion joints are engineered to provide flexibility and stress relief, reducing the risk of structural fatigue and preventing damage to critical equipment.

At the core of the Elbow Pressure Balanced Expansion Joint’s functionality lies a harmonious combination of two integral components: the standard inline-bellows and the pressure-balancing bellows unit, both bellows are connected through a set of tie-rods or external hardware. The traditional bellows proficiently absorb axial and angular movements, while the balancing bellows, installed in the opposite direction to the elbow, ensure equilibrium by neutralizing the internal pressure forces via the tie-rods.

More About Elbow Pressure Balanced Expansion JointsView Product Page

When the piping system experiences thermal expansion or contraction, the Elbow Pressure Balanced Expansion Joint flexes accordingly to accommodate the movement while maintaining structural integrity. The balancing bellows unit operates in tandem with the traditional bellows, exerting an equal yet opposite force to balance the pressure thrust generated through the tie-rods connecting both bellows. Consequently, this innovative design mitigates excessive loading on anchors and supports, minimizing the risk of stress-induced failure and fatigue.

The strategic implementation of Elbow Pressure Balanced Expansion Joints yields several profound advantages, making them a preferred choice for demanding piping systems:

- Precise Stress Absorption: The Elbow Pressure Balanced Expansion Joint’s ability to effectively absorb axial and lateral movements, vibrations, and thermal expansions, while containing pressure thrust, prevents undue stress on adjoining components, such as pumps, turbines, and valves, enhancing the overall reliability and longevity of the system.

- Space Optimization: Ideal for constrained spaces, these expansion joints offer a compact and space-efficient solution by obviating the need for elongated straight sections and additional supports, streamlining installation and maintenance efforts.

- Pressure Thrust Control: Incorporating a balancing bellows unit effectively balances the internal pressure thrust forces, protecting anchors, supports and/or equipment from overloading and potential damage.

- Improved System Integrity: By minimizing mechanical stresses and maintaining pressure equilibrium, Elbow Pressure Balanced Expansion Joints foster a robust and dependable piping system, even under challenging operating conditions.

Elbow Pressure Balanced Expansion Joints have many applications in various industries, including petrochemical and refineries to mitigate thermal expansions and vibrations in intricate piping networks associated with high-temperature processes and power plants for absorbing thermal cycles, pressure fluctuations, and dynamic loads induced by turbines and compressors. This type of expansion joint can be used to enable thermal movement absorption in large-scale heating, ventilation, and air conditioning systems.