Frequently Asked Questions

A 3-coat paint system consists of a primary coat, an intermediate coat, and a top coat of a color or finish typically specified by the end user.

View some of our products manufactured with a three coat paint system.

Sweco Fab, Inc., our subsidiary, holds the ASME U-Stamp which gives us the ability to manufacture and work on unfired pressure vessels. Sweco acquired the ASME U-stamp in 1962 and has maintained it through-out the regular audits. The U-Stamp represents ASME's section VIII Division 1; rules for the construction of pressure vessels. In order to obtain the U-Stamp, Sweco Fab was required to meet ASME's guidelines for the design, fabrication, inspection, and testing of Pressure Vessels. In order to maintain the U-stamp, we regularly update our designs and fabrication processes while undergoing routine examinations and inspections.

Pressure Vessel Manufactured by Sweco Fab

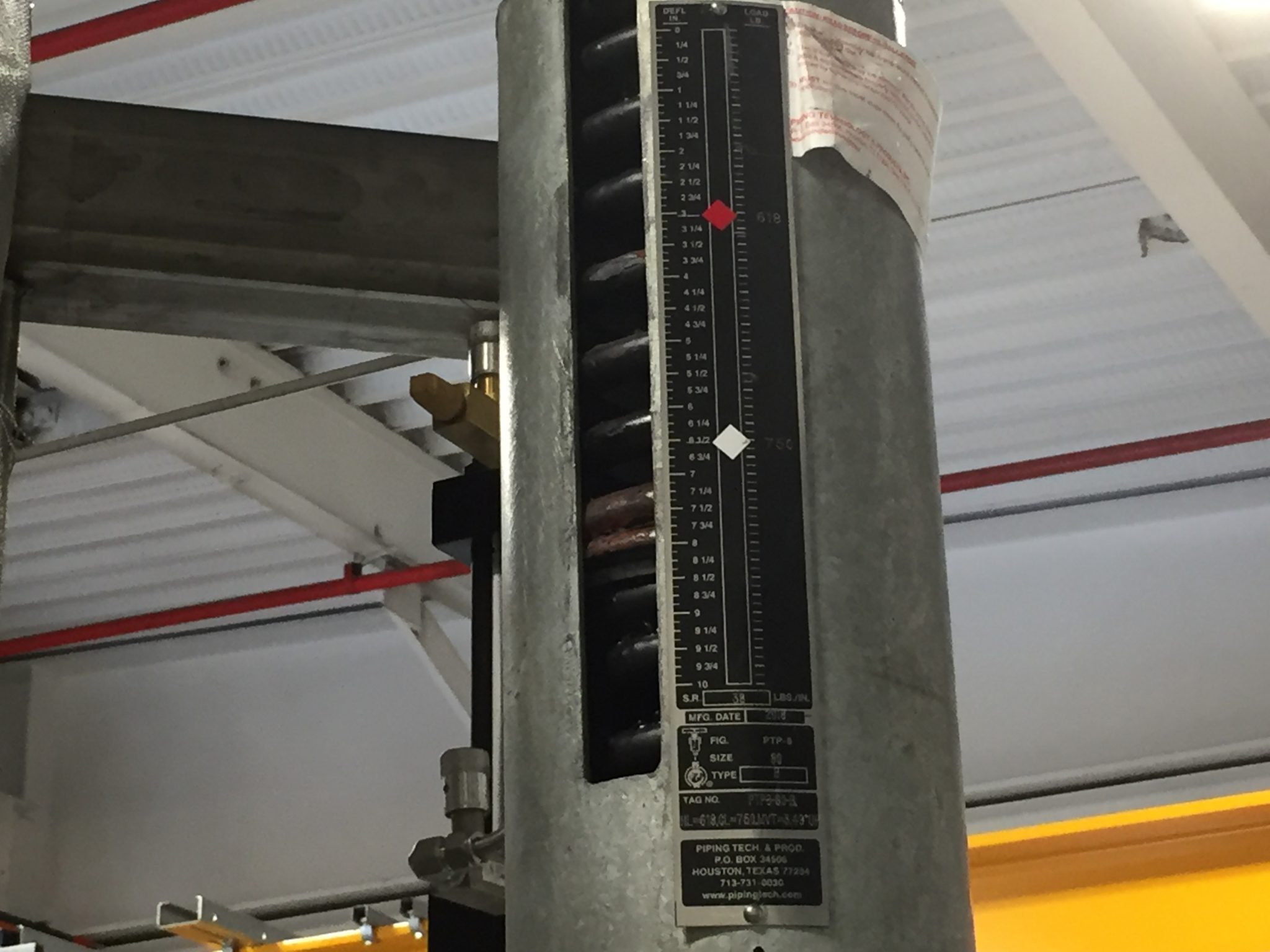

Cold Load is the initial load setting where the spring will be set at the start of the operating cycle. Hot Load is the calculated load at your final operating condition. Movement is the distance between the hot and cold load.

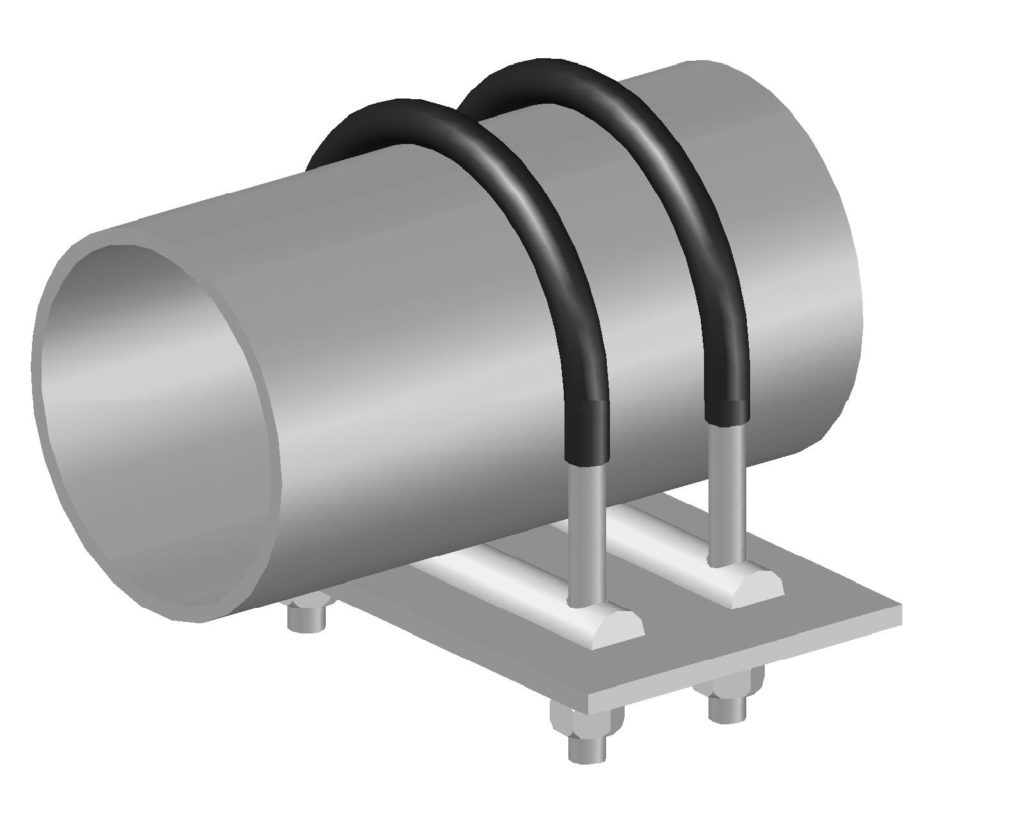

The most common method for supporting vertical piping would be to first weld shear lugs into position, and then utilize a riser clamp which straddles the pipe. The load is then transferred by the riser clamp’s load bolts through hanger rod connections to our supporting structure.

22″ Diameter Riser Clamps

Resting supports for piping could refer to a variety of supports that's main purpose is to support the pipe weight and is generally used where little or no pipe movement is anticipated.

Polyurethane Pipe Saddle Resting Support

FRP stands for fiberglass reinforced plastic. It Is a material that is made up of a polymer matrix reinforced with fibers. At Piping Technology, we provide FRP wear pads that are fabricated from FRP pipe. These pads are secured to pipes using an epoxy adhesive.

FRP Wear Pads

Pipe trunnions could refer to a variety of supports that mainly function to support the pipe weight and generally used where little or no pipe movement is anticipated.

Insulated Trunnions

The centerline of the pipe is considered as the imaginary axis which runs longitudinally along the pipe through the midpoint of its diameter.

The centerline of the pipe is shown on Fig. 48Pipe Saddle drawing.

Each pipe support has its own load carrying capacities depending upon its function. One must check the load limits of that particular support to determine it's full load carrying capacity.

The weight that can be supported by a pipe is dependent on numerousfactors, including the pipe diameter, pipe wall thickness, operating temperature of the piping system and the material of the pipe.

F-Type Variable Spring Supports designed for Operating Conditions Ranging from Loads of 1,750 lbs. to 21,280 lbs.

Axial pipe restraint means that the support will incorporate some means of positively restricting the movement of the supported pipe along its longitudinal access in line with the pipe.

The objective of the burst test is to determine the ultimate pressure resistance. This test is primarily conducted on bellows. Normally, hydraulic pressure is slowly increased until failure occurs. Based on the burst test results, a safety factor is applied. This establishes the ultimate pressure rating.

Burst Testing

Sag is the deflection of pipe between the supported ends.

Axial Deflection

In generalterms, a pipe support is designed to carry the pipe weight while simultaneouslypermitting deflection in vertical and/or horizontal directions. Whereas,restraints are intended to restrict movement as either a guiding element or an anchoring device.

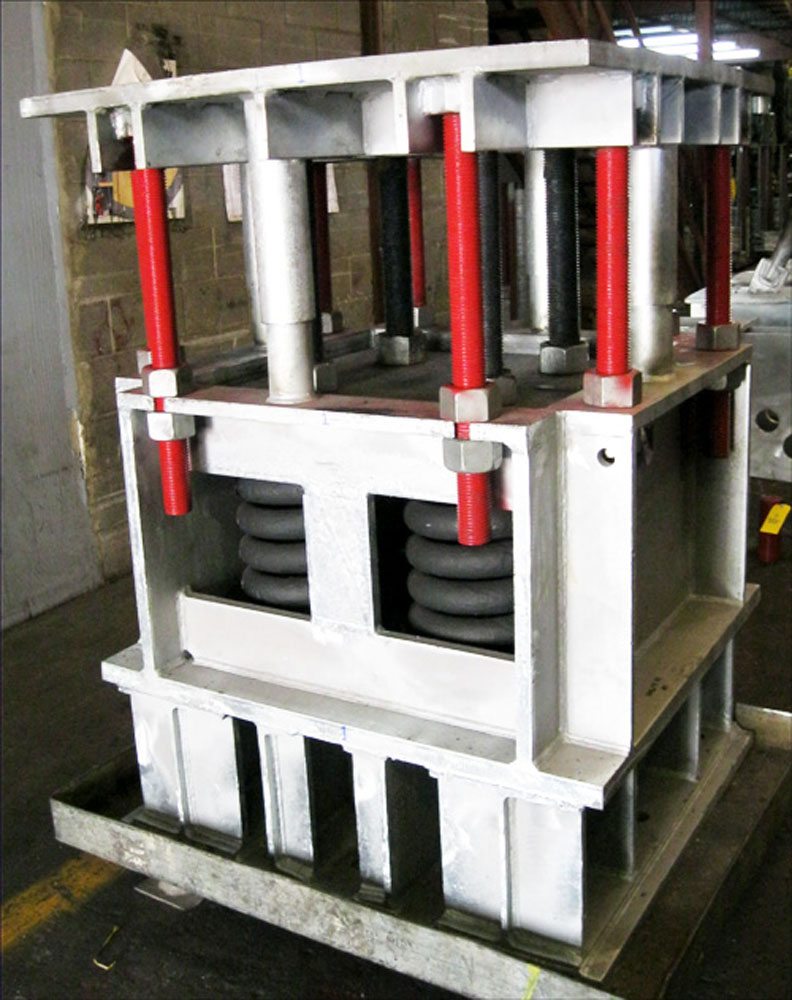

Big Ton Spring Support

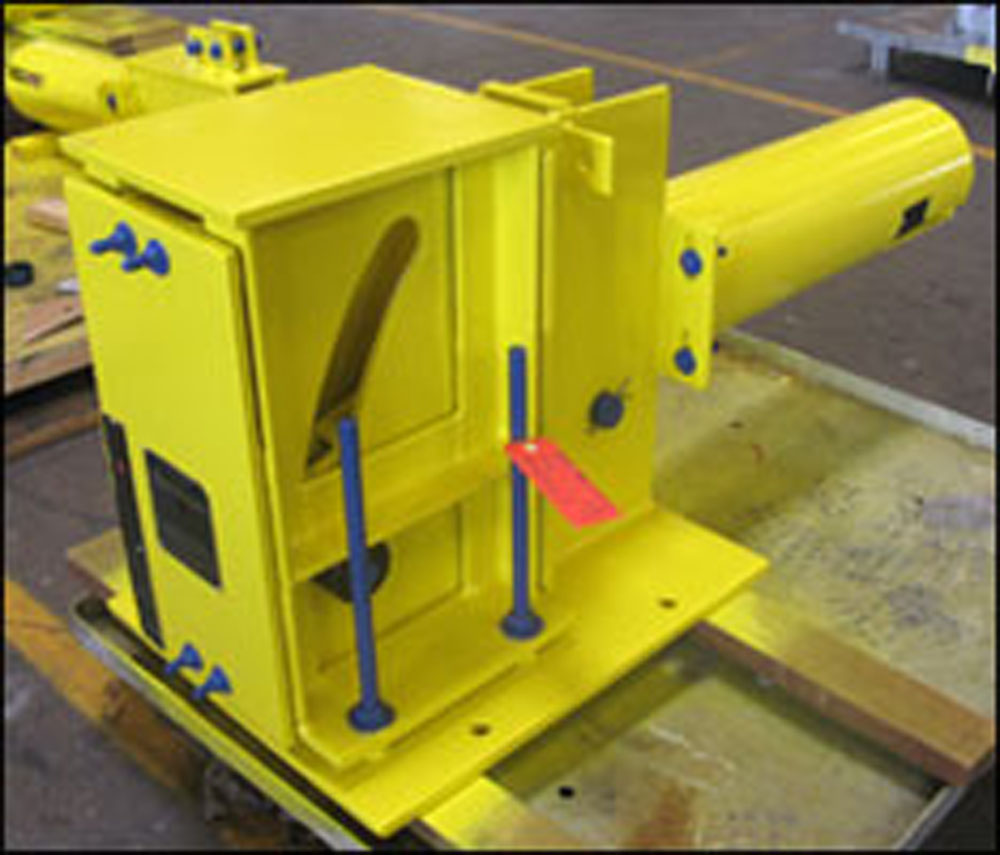

Flexible Pipe Restraints

When determining the required length of a u-bolt, one should provide a leg length which extends from the centerline of the pipe to end of the threaded portion, while still permitting a hexnut/locknut combination with full thread engagement.

TPI Pipe

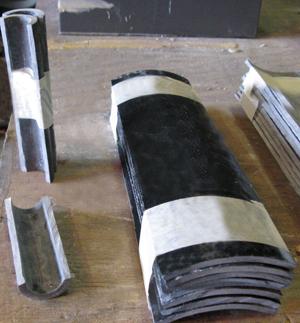

Permali was initially used for cryogenic pipe supports because of its insulating properties for low temperature applications along with its ability to be machined to fit pipe contours.

Pipe Supports with Permali

Permali® is a high density insulating material comprised of layers of beech wood. The total insulation thickness is obtained by bonding the individual layers. This material is primarily used in cold temperature applications ranging from ambient conditions down to -300 degrees F.

Cryogenic Supports with Permali Insulation

An isolation pad material isbelting material designed to absorb shock.

Isolation Pad on a Hold-Down Pipe Clamp

In general, the procedure of painting carbon steel material acts as protective coating to inhibit rust and/or any other chemical reactions in thesurrounding atmosphere.

Painted Constant Spring Supports

Axial pipe movement would be defined as the movement along the centerlineaxis of the pipe system.

Travel Stop – A device which temporarily locks the movable parts of a Spring Hanger in a fixed position. When the travel stops are installed, the static load (weight of the pipe) will be supported by the spring’s casing (instead of the spring’s coil) making it a rigid support. This static load is then transferred to the supporting structure enabling the piping system to maintain the desired elevation difference between the pipe and supporting steel during erection and/or Hydrostatic Testing.

Liquid Natural Gas – It is light hydrocarbon gasses that are compressed into a liquid state for cheaper and more efficient transportation.

It is a plate welded to the outer arch of a pipe to restrict the sliding of the insulation assembly against the pipe wall.

The most common area in a pipe to find deformations is in the middle. This area is the farthest distance away from the supports.

FRP Wear Pads, also known as non-metallic wear pads, caneliminatemetal to metal contact and electrically isolate the piping from the pipe rack and other metal structural elements..

Non-Metallic Wear Pad (FRP Pad)

The additional load will distribute throughout the system if there are other springs, however, it could bottom out the constant before it distributes the load.

In terms of total cost, installing pipes above ground will be more expensive because you must consider the foundation, structural steel elements and support elements included in the project.

Welding is the most common method of attaching the slide bearing plate to supporting metal structures. When this approach is used a “lip” must be built since the welding's extreme temperature may break the bond between the low-friction material and the metal plate. A 0.25 inch “lip” is adequate for most welded installations. When welding cannot be used (for safety or other reasons) to attach the slide plates, bolting is the most common substitute.

To compensate for pipe movement, a designer may choose from a variety of clevis hangers, roller hangers, and adjustable bands to support the pipe. These are linked to the supporting structure with rods and other hardware components. Beam attachments and other accessories are attached to the supporting structure to complete the pipe hanger assembly. All of these components must be strong enough to support the loads in the environment where they are installed.

Furnace Springs are are almost always coated with red oxide primer in order to avoid any potential hazards when exposed to high temperatures.

For Constant Support Hangers, a device attached to a movable arm of a Constant Support Hanger, used to indicate the reading on the Travel Scale in order to show the vertical pipe movement. For Variable Spring Hangers, the spring load plate which indicates the reading on the Load/Travel scale in order to show the vertical pipe movement.

Travel Stop – A device which temporarily locks the movable parts of a Spring Hanger in a fixed position. When the travel stops are installed, the static load (weight of the pipe) will be supported by the spring’s casing (instead of the spring’s coil) making it a rigid support. This static load is then transferred to the supporting structure enabling the piping system to maintain the desired elevation difference between the pipe and supporting steel during erection and/or Hydrostatic Testing.

Constant Springs should be replaced when there are signs of excessive corrosion or fatigue. Also, consider if there need to be modifications due to the operating conditions — especially if hindering the operation of that component.

No, the cold and hot load should be the same on the Constant Spring Supports. However, the load variation of a constant support is required by standards to be within the allowable variation of 6%.

D.N.V. is Det Norske Veritas which is a risk managing company. They have standards we meet in order for our products to be safe.