Frequently Asked Questions

“Spring can” is the general term used to describe either variable or constant spring supports.

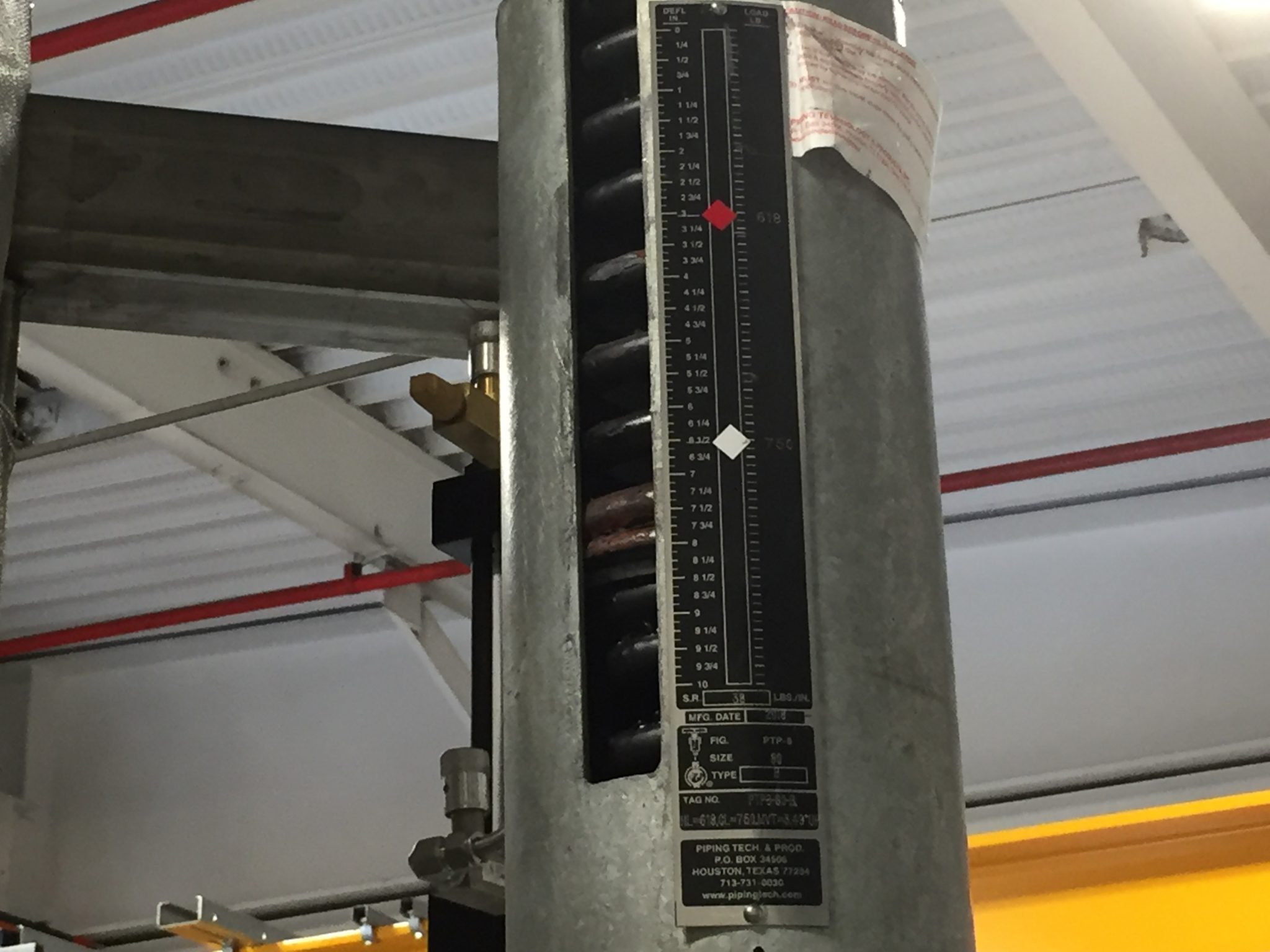

Custom Spring Can with Slide Plates

The “cold” setting of a variable spring support refers to the installed position and the associated load being carried by the support at that time. The “hot” setting refers to the operating position and subsequently the associated load being carried by the support at that time.

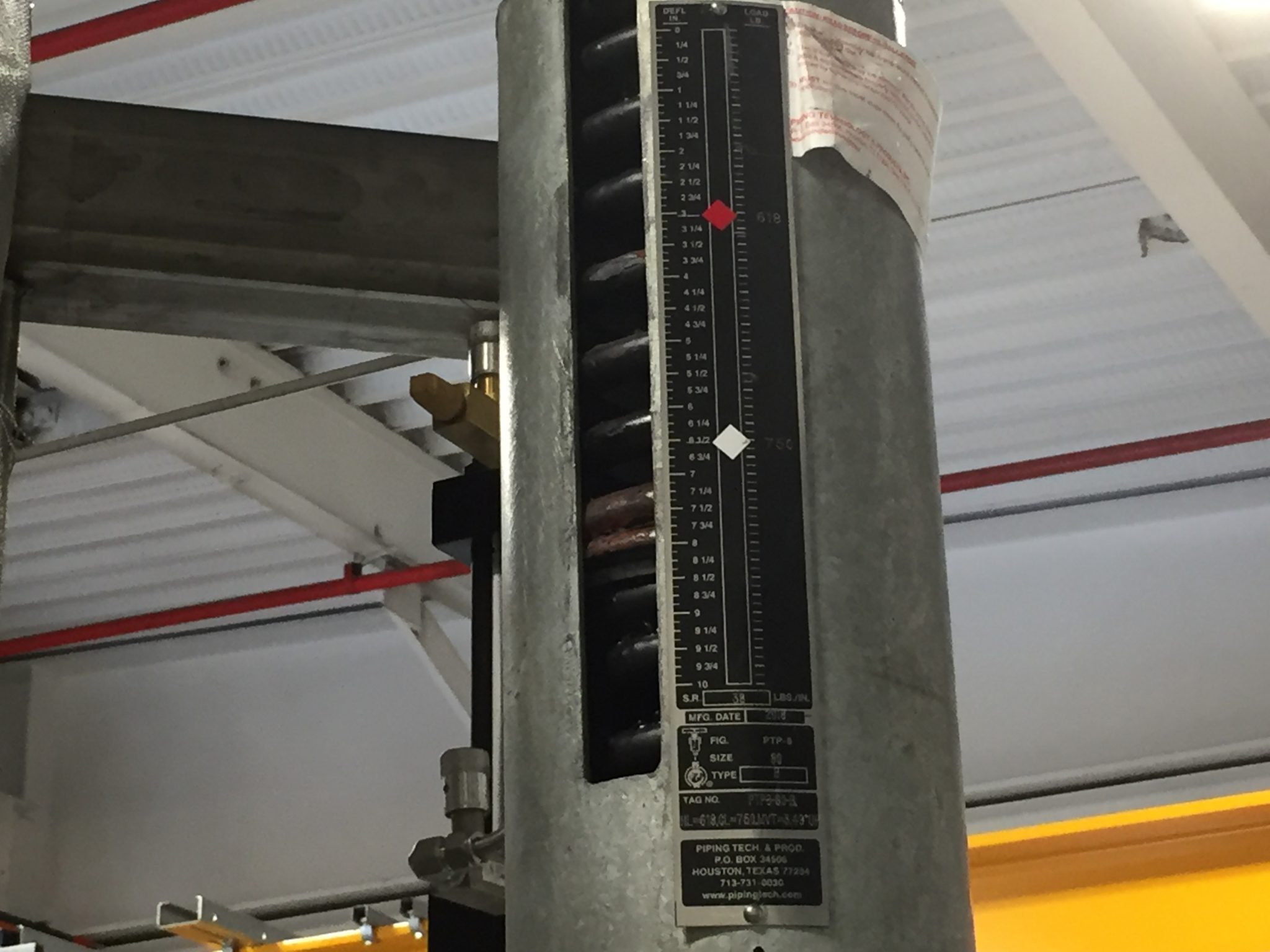

Cold Setting Indicated by the White Diamond on a Variable Spring Support

A spring hanger is a subset of either variable or constant spring supports that attach directly to structural steel components and are located above the supported member.

Constant Spring Hangers

Cold Spring is intentional deformation of piping during assembly to produce a desired initial displacement and reaction. Cold spring is beneficial in that it serves to balance the magnitude of the reaction under initial and extreme displacement conditions

Cold Load on Variable Spring

Use this 10-point operational integrity check list when inspecting spring supports in the field:

- Beam attachment

- Beam attachment pin

- Spring hanger attachment

- Load flange movement

- Spring coil corrosion

- Check load indication for hot load

- Note load deviations

- Turnbuckle/locknuts

- Threaded rod/weldless eye, hex nuts

- Pipe clamp attachment pin

For more information, or assistance with accomplishing this check-list in the field, please see our field services page.

Corroded Variable Spring Support

Variable springs always must have a difference in load between the hot and cold settings. Whereas in constant springs, the load remains consistent. Additionally, in general, constant springs can provide for a higher amount of travel. (Read More in our Technical Bulletin section)

Variable Spring Supports

When referring to adjusting a spring hanger, first you must define whether or not your are talking about a length adjustment or a load adjustment.When modifying the length of a spring support, you would utilize its load column to change its original length position. When adjusting the load of a variables pring hanger, you would remove the travel stops and then alter the load by modifying the position of the load column. When adjusting the load of aconstant spring hanger, you would adjust the load by changing the initial compression seen at the spring coil.

Constant Spring Hangers

To check the load setting, examine the position of the bottom of the load indicator with respect to the scale on the spring’s tag. Read from the bottom of the load indicator to determine position. Next, look at the size of the spring located on the tag. Then, refer to the appropriate load and travel table (Constant Load & Travel Table or Variable Load and Travel Table) to determine the respective spring rate and the “0” load (minimum working range load). Multiply the spring rate by the position value and add that to the “0” load value.

Spring supports should always be locked when the load is removed at thatsupport location. The locking prevents the stored energy of the spring coilfrom suddenly releasing when the spring is disconnected.

We refer to our spring supports as any assembly which includes a spring(either variable or constant) that can accommodate both a pipe load and a pipemovement.

Variable Springs Constant Springs

The spring hanger must be locked because in most instances, the hydro test exceeds the installed load and without the stops, the spring coil would deflect when subjected to that higher load. Secondarily, the travel stops act to bypass the coil so that the rigid components that make up the entire assembly are subjected to that hydro test load and it is not “seen” by the spring coil.

The major point to consider while de-blocking a spring hanger would be to makesure that you are at your true cold condition which means that you can applythe correct installed load that the spring is set to.

Variable Spring Set to Cold Load of 10,413 lb.

The pins are removed from a spring hanger after all hydro-testing has been completed, all piping connections have been finalized, and when all starting operations have been completed in the pipe system.

See the videos below on how to remove the travel stops from a spring hanger.

- How to Remove the Travel Stops from a Variable Spring Support

- How to Remove the Travel Stops from a Constant Spring Support

Travel Stops Shown on a Variable Spring

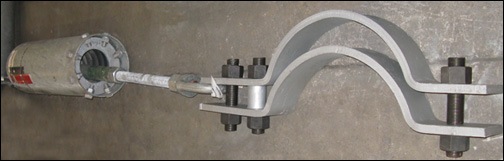

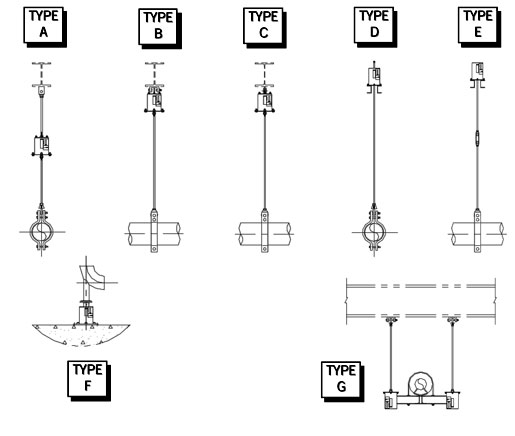

For hanger type variable springs types, a, b, c, d, e, and g, you can utilize the minimum loaded length value (x in the PT&P catalog) and add to that a value equal to your cold load minus the minimum cold load (top red line of the springchart) divided by the spring rate. For f type variable springs, the loadedlength can be set at any height between the minimum and maximum values referenced in the catalog regardless of the initial cold load. The only caveat would be that when dealing with downward movement, one should always ensure that the installed height is large enough to accommodate that downward movementwithout interfering with the spring housing (or the b dimension as referencedin the catalog).

Various Spring Support Assemblies

The tension on a spring hanger is adjusted by turning the load column.Increasing the load seen at the spring would be accomplished by tightening(turning clockwise) the load column at the connecting rod. Conversely, loosening (turning counter clockwise) the load column would cause the spring load to decrease.

Variable Spring and Clamp

In order to remove a spring support, first you must ensure that the spring is at its designed cold (installed) position. Next, re-install the travel stop(s) in the support. Then, provide adequate temporary support for the piping system. Once you have adequate support, you can release the load from the spring. Finally, remove the spring support from the piping system.

Variable Spring Support with Travel Stops in Place

The maximum load that a standard variable spring can support is 50,000 lbs. The maximum load that a standard constant spring can support is 90,000 lbs. A big ton spring support can be be used for loads greater than these standards.

Constant Spring Designed for a 35, 144 lb. Load

The support rods are generally used to attach the spring to the stationary support member or structural steel and to transfer the load from the pipe onto the spring. Rods are generally utilized because they can be readily modified to fit existing site conditions.

Variable Spring and Rod Assemblies

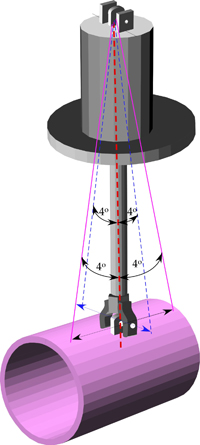

Yes. The maximum allowable movement for constant spring hangers per MSSstandard is + or – 4 degree swing angle which would be associated with thelateral movement.

Constant Spring Hanger Pipe Supports

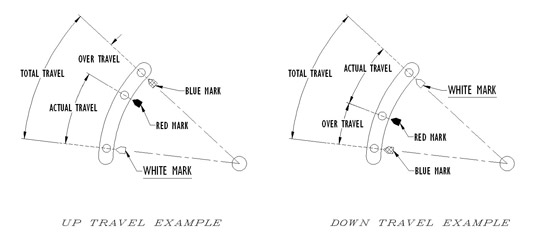

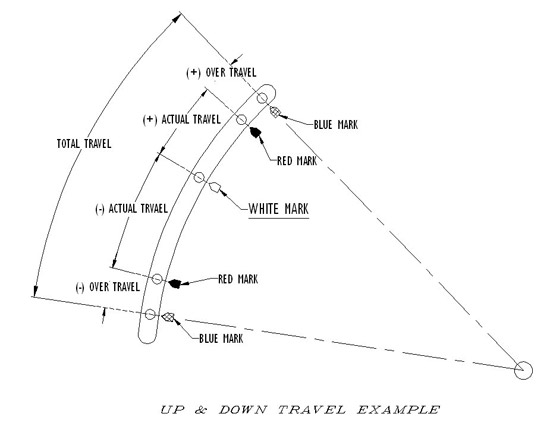

Red, White and Blue Marks:

All constants are shipped with at least 3 color-coded rivets (red, white and blue).

Red: operating (HOT) position

White: installation (COLD) position

Blue: over travel (MAX AVAILABLE) position

Below are sketches of one direction vertical travel:

Below is a sketch of dual direction vertical travel:

Resilient springs provide variable lifting force during pipe deflection.

Constant Effort provides constant lifting force while permitting deflection

We offer seven different configurations for Variable Spring Supports (Type A, B, C, D, E, F, G). Click here for an in-depth explanation of each configuration.

Diagram of each Variable Support Type

The additional load will distribute throughout the system if there are other springs, however, it could bottom out the constant before it distributes the load.

A temperature change would mean a change in movement, which may or may not need a new spring hanger. If the travel does not take the spring out of its operating range, then you would not have to change anything. However, if it does, then the spring will need to be replaced.

To compensate for pipe movement, a designer may choose from a variety of clevis hangers, roller hangers, and adjustable bands to support the pipe. These are linked to the supporting structure with rods and other hardware components. Beam attachments and other accessories are attached to the supporting structure to complete the pipe hanger assembly. All of these components must be strong enough to support the loads in the environment where they are installed.

Furnace Springs are are almost always coated with red oxide primer in order to avoid any potential hazards when exposed to high temperatures.

Furnace springs operate in much the same way as other variable spring supports. They are designed to support the pipe or tubes that are subjected to vertical thermal movement. The design changes are necessary because furnace springs are exposed to extreme temperatures. Standard springs are usually hot dipped galvanized, which, when exposed to high temperatures, tends to melt the zinc coating. The molten zinc can then cause damage to the surrounding pipe and equipment.

Furnace Spring Assemblies up to 13,000 lbs. for a Chemical Refinery

Putting two springs in a series makes a longer spring and reduces the spring rate by a function of how much longer the overall coil is made, whereas putting them in parallel does not change the spring rate but increases the load capacity.

When designing a spring hanger, you want to consider the following:

Have questions regarding our products or need a quote? Contact our product specialist

A Constant Spring Hanger allows for large thermal movements, with standard designs up to 14” and custom designs 36” or greater.

The only way to reduce the amount of force the spring is pushing back with is to reduce the amount of spring deflection.

Base Type Variable Spring Support

No, one rod goes all the way through the can and attaches on the top.

200 E Type Horizontal Constant Spring Supports

You use multiple springs in a pipe system to accommodate more travel. When you stack multiple springs in a series, it provides a softer spring rate.

Chart Showing How Much Movement Each Variable Type Can Take