Frequently Asked Questions

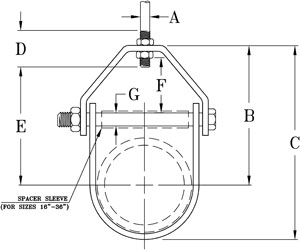

A trapeze hanger is a support assembly consisting of parallel vertical rods which are suspended from a structure and connected at their lower ends by a horizontal member from which the pipe is supported. It is used for the suspension of pipe from two rods where longitudinal movement due to expansion or contraction may occur.

Pipe Saddles to be used in a Trapeze Hanger Assembly

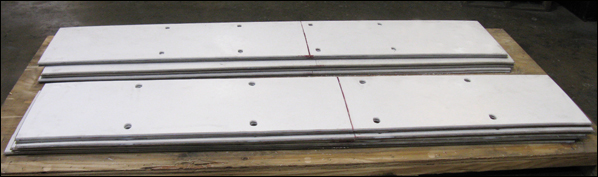

A PTFE bearing pad is a slide plate made up of PTFE, 25% glass filled, material that provides a low coefficient of friction for most combinations of temperature and load. For most applications, PTFE, 25% Glass Filled, is adequate when the temperature is less than 400 degrees F.

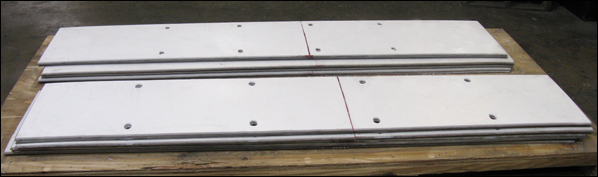

PTFE, 25% Glass Filled Slide Plates

A welding lug is a pipe support component consisting of a single plate of varying thickness, depending upon the load, which is welded to either a supporting structure or a supported pipe and used to join other support components together using pins.

Welding Lug Shown on a Constant Spring Support

There are a variety of ways to attach a flat plate, such as a slide plate, to a pipe includingwelding or bonding.

Shear lugs are primarily required whenever a clamping support is being loaded in the axial direction of the pipe. It should be noted that we are not relying upon the clamping force of the support to withstand the axial load, but we are relying on the shear lugs and the clamping contact to absorb the axial load.

The most common method of attaching a slide bearing plate to supporting metal structures is through welding.When this approach is used a “lip” must be built since the welding's extreme temperature may break the bond between the low-friction material and the metal plate. A 0.25 inch “lip” is adequate for most welded installations. When welding cannot be used (for safety or other reasons) to attach the slide plates, bolting is the most common substitute.

PTFE Slide Plates Welded to Metal Pipe Saddles

The strength of the hanger rod is dependent upon its diameter. The smallest standard rod diameter for Piping Technology is .5 inch with a load capacity of 1,350 lb. and the largest with a 3 inch diameter and a load capacity of 60,100 lb.

More about hanger rods

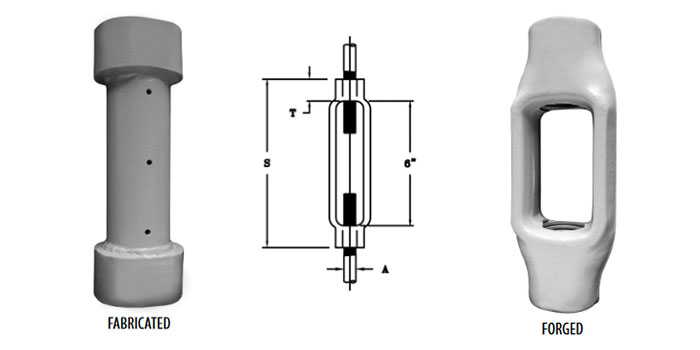

A turnbuckle provides two functions in a piping system. The first function would be to provide a minimum amount of adjustment for any field inconsistencies. The second function would be to provide the minimum amount of resistance when transferring load to the remainder of the support components.

Turnbuckle fabricated and forged

A lug plate is a component that is welded to existing structural steel members and allows another pipe support component to be pinned at that location.

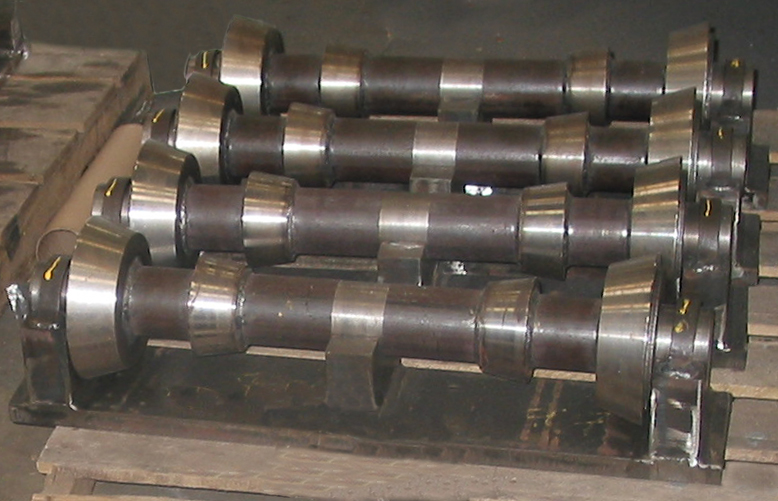

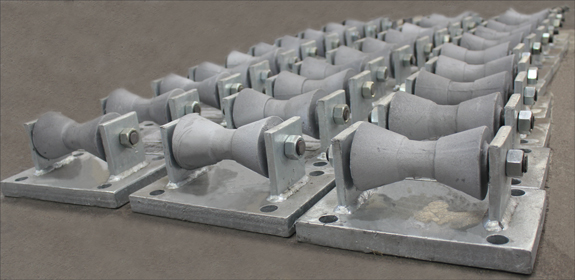

Rollers are generally utilized when axial movement at the support location would generate swing angles in excess of 4 degrees on hanger type supports or when movement is greater than approximately an inch on base type supports.

Roller Stands for a Cooling Tower

When installing clevises, first you should disengage the pin connection of the clevis. Then align the clevis pin holes with the existing component. Place the pin through the holes of the clevis an component and place the lock in the pin.

Clevis and Pin Connected to a Rod

U-bolts can be utilized as pipe guides when the horizontal forces are relatively small (usually 10% or less) compared with the anticipated vertical load.

U-Bolt Pipe Support Assembly

An eye rod is a hanger rod where the lower section consists of either a formed portion (to form an “eye”) of the rod or a welded pad (to form an “eye”) with a hole to attach to bolts or pins.

240 PT&P Figure 110 Welded Eye Rods

A three-bolt clamp is normally used for horizontal insulated piping, which utilizes clamping bolts to attach the clamp to the pipe and a separate Load Bolt to transfer the piping weight to the remainder of the Pipe Hanger Assembly from a point outside the insulation.

Three-bolt Pipe Clamps

Saddle coverings are used with insulated pipes in order to provide protection to the insulation at points of support. Roller stands, elbow supports, and other items can be supplied in adjustable models which allow field crews to make easy installations.

See the following article for FRP Wear Pad Installation: www.pipingtech.com/technical/im/frp-pad.htm

There is 3″ ofadjustment permitted for a turnbuckle.

Billet Style Turnbuckle

Roller hangers are used for the suspension of pipe from a single rod where horizontal movement may occur because of expansion or contraction.

Steel washer plates are components used on top of channels or angles to support pipe with rods or U-bolts.

A bearing plate is also referred to as a slide plate. It is a component that can be fabricated from a variety of materials including graphite, PTFE, 25% glass filled, stainless steel, and bronzphite. The purpose of slide plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

PTFE, 25% Glass Filled Slide Plates

Yes, u-bolts can beused on insulated steam lines.

U-Bolt Assembly

All pipe support components are fabricated with a minimum factor of safety of 2.5.

At 650˚F, the clamp material is approaching its maximum temperature rating so we would recommend an alloy material above that temperature.

For offshore we have topaint the rollers or coat them in neoprene to withstand the harsh environment.

Painted Pipe Rollers

The roller support is designed to be used with rigid insulation and must be sized according to theouter diameter of the insulation.

Eight Polyurethane Pipe Rollers for a Gas Plant

The Figure83 clevis hangers support vertical pipe, so they do not resist lateral or axial movement, but support the vertical piping and resist vertical movement of the pipe.

Clevis Hanger

The adjustment for a clevis hanger is obtained by the threaded rod connection and the upper section of the clevis hanger. The space between the pipe’s outer surface and the top section of the clevis hanger can be utilized to adjust the overall elevation of the hanger assembly.

Galvanized Clevis Hanger

In general, hanger supports, be they rigid rod hangers, variable spring hangers or constant spring hangers, all use threaded connections between our existing structural steel component and our pipe attachment point. These threaded components are used to meet both our elevation difference and to provide some adjustment per actual site conditions. The threaded components could consist of all threaded rods, eye rods, clevises, turnbuckles, etc.

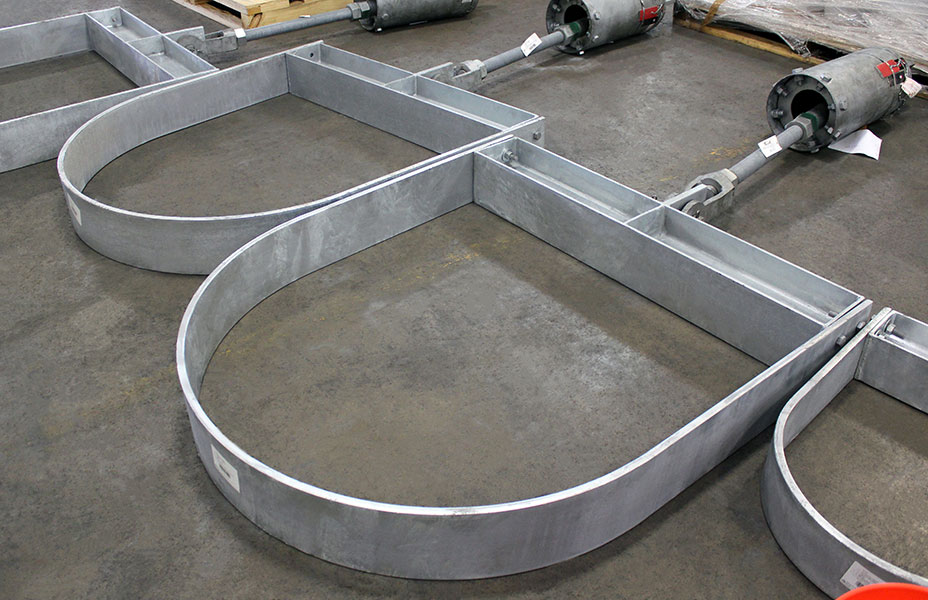

Cold Insulated Pipe Shoes for an LNG Plant

Weldless Eye Nuts and Fig. 95 Forged Steel Clevises