Problem:

A refinery required stress analyses done for three piping systems. The springs installed in all the three lines had bottomed out and did not have the load and travel information for replacing the spring supports.

|

|

|

|

|

|

|

|

In addition, the client did not have the As-built Iso drawings or piping drawings for two of the three lines and did not have any Iso drawings for the third line.

The client requested PT&P to provide an estimate to prepare as-built isometric drawings for the three lines and perform the stress analyses for the lines based on the Iso drawings generated by PT&P to provide the correct replacement spring size for the three lines.

PT&P provided a quote to perform a detailed line walk to gather the information for preparing the Iso drawings, generate the Iso drawings and perform stress analyses for the three lines. The client provided PT&P the line specifications and process parameters.

Solution:

After receipt of the order for generating Iso drawings and for performing pipe stress analyses for the three piping systems, PT&P scheduled visits to the plant site to gather the information.

Step 1 – Generating Iso Drawings

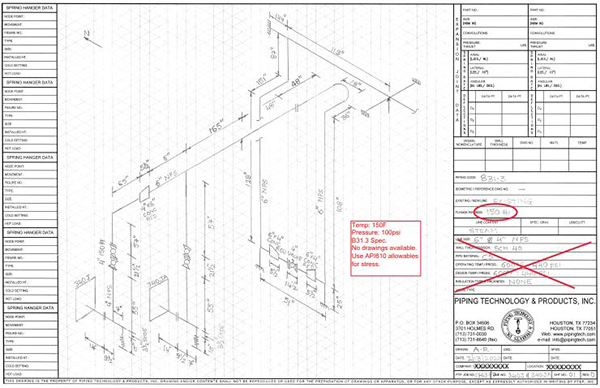

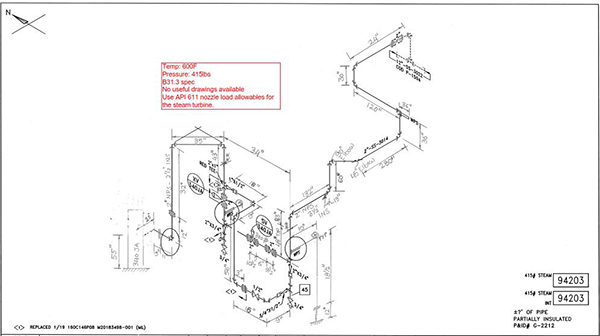

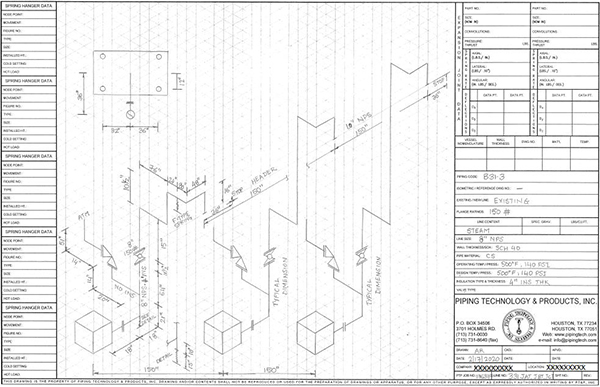

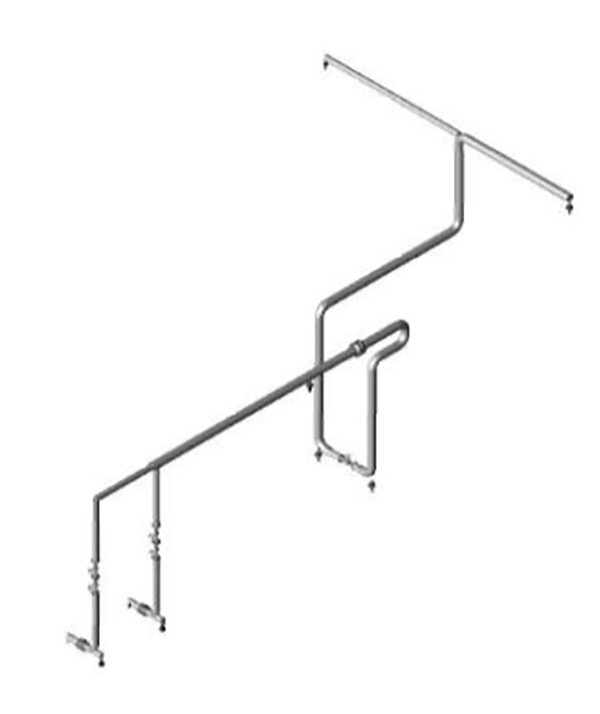

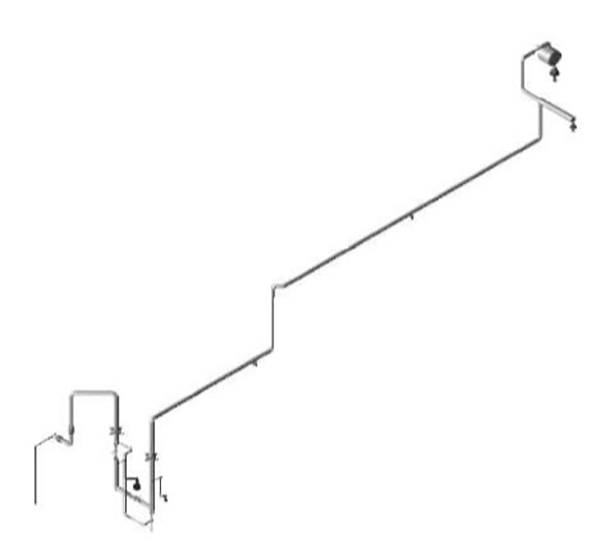

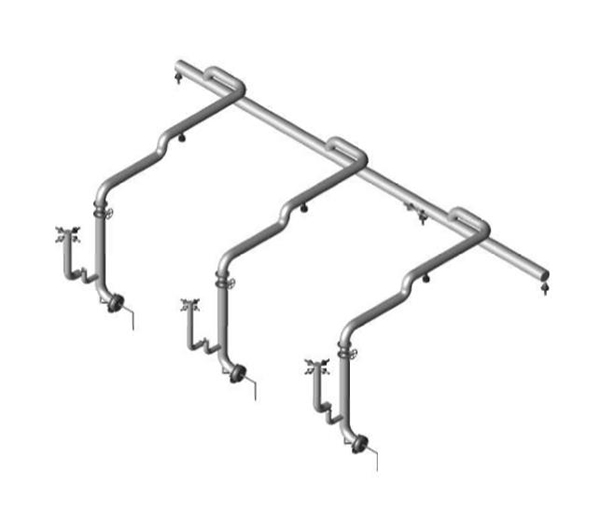

Based on the information (piping dimensions, existing support type, and location and piping component/ equipment type and location) gathered during the site visit, PT&P generated and submitted Iso drawings for the three lines to the client for review and approval.

Step 2 – Perform pipe stress analyses using CAESAR II

Upon receipt of the approved Iso drawings from the client, pipe stress analyses for the three lines/ systems were done by PT&P Pipe Stress Engineer with 30+ years of experience and former Secretary of Texas Society of Professional Engineers.

PT&P recommended new replacement spring cans for the existing spring cans that had bottomed out for the three piping systems. All other existing supports were considered during the pipe stress analyses and were left as-is. PT&P made recommendations for solutions for any overstresses in the piping and for few added guide supports for the lines.

One of the lines was supported by a 12ft long horizontal dummy leg which by far exceeds the allowable dummy leg length. PT&P recommended checking for any cracks at the elbow connecting the dummy leg and to provide reinforcing pad at the elbow if necessary. Sag was also visible in the piping during stress analysis at that location and hence additional support was recommended.

Summary:

PT&P has 70+ design engineers and a dedicated field service team with the experience and ability to visit the plants and generate Iso drawings for piping that do not have any as-built drawings.

PT&P has over 30 years of pipe stress analysis experience. PT&P started the business as a pipe stress company in 1975 and eventually grew its business into the manufacturing of pipe supports, expansion joints, and pressure vessels.

While PT&P does not have the range of expertise of a typical engineering firm, we have extraordinarily deep expertise in Piping and pipe stress analysis. PT&P is able to effectively serve small capital projects because it does not carry the overhead of a traditional professional services firm.