PT&P has extensive experience in assisting our customers with resolving vibration issues in its piping system.

PT&P has designed its portfolio of solutions to make full use of:

- Stiffening – when a solution is added to hold down the piping at an individual point, it causes the Pipe to resist movement that is caused by vibration energy. Stiffening is good at limiting movement at an individual point in the system. However, it does not remove vibration energy from the piping system so vibration will continue down the line. Examples of stiffening solutions include U-Bolts, Hold Downs, and Clamps.

- Energy Dampening – when an energy dampening solution is added, it converts mechanical energy from vibration to heat. This is typically done with different types of friction including Viscoelasticity and Hysteresis. Energy dampening removes vibration energy from the piping system and reduces the amplitude of vibration that passes down the line. PT&P uses Vibration Pads for Energy Dampening and is currently working on additional options for different vibration scenarios.

- Isolation – isolation solutions are used to keep vibration energy from piping being passed to the structure. Springs and steel cables are 2 examples of items used for isolation.

View our Case study on Vibration in Piping

PT&P’s portfolio of products that can assist with pipe vibration issues include:

- Super U-Bolt – a U-Bolt can be used as a lightweight stiffening solution. PT&P’s Super U-Bolt can be ordered with a Vibration Pad to add Energy Dampening to the solution.

- Clamps – PT&P offers a variety of clamps from lighter to heavier weight. PT&P Clamps can be ordered with Vibration Pads to add energy dampening.

- Hold Downs – Hold-Downs are a heavyweight stiffening solution. PT&P’s Hold Downs can be ordered with Vibration Pads to add Energy Dampening.

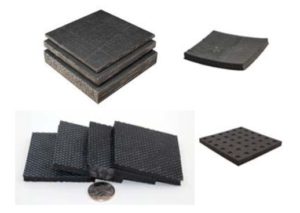

- Vibration Pads – Vibration pads can be ordered separately or in combination with other products to provide Energy Dampening. PT&P uses a variety of different vibration pads that are optimized for different frequencies and loads as well as price points.

- Sway Brace – This solution is used to stiffen the Piping by using the spring rate of a Helical Spring to oppose the mechanical energy from vibration. PT&P sway braces are also used in other parts of the overall system including Tanks and Pressure Vessels.

PT&P Sway Braces

- Snubbers – PT&P has one of the most extensive lines of Mechanical and Hydraulic Snubbers in the world. Snubbers are best used for occasional vibration or large transient loads. The design of a snubber is not well suited to continuous vibration.

Pipe Vibration Services

PT&P has extensive experience in assessing vibration in piping systems. Our services include:

- Product Selection Support – when you order products from PT&P, we include support on product selection as part of the order. You can reach an expert from PT&P who can assist in providing a recommended product based on a description of the problem and additional information including pictures, Isometrics, and accelerometer data.

- Pipe Vibration Assessment and Solution – PT&P also provides services to determine the root cause of vibration and design a solution after determination of root cause. PT&P Field Engineers will assess the issue at the customer site and collect relevant data. This will be assessed with the relevant experts at PT&P to isolate the root cause. Field Engineering will then work with Design Engineering to develop the appropriate solution. NOTE: PT&P’s expertise is in Piping systems. If the root cause of vibration is in areas such as rotating equipment, PT&P may not be able to design the appropriate solution without engaging outside expertise.

- Pipe Stress Analysis – Pipe Stress Analysis can be useful in analyzing potential causes of vibration by assessing whether the Piping is properly supported. When the piping system is not properly supported, it leads to too much flexibility in the piping system which makes it vulnerable to vibration.

View PT&P’s Pipe Vibration Solutions PDF

Top