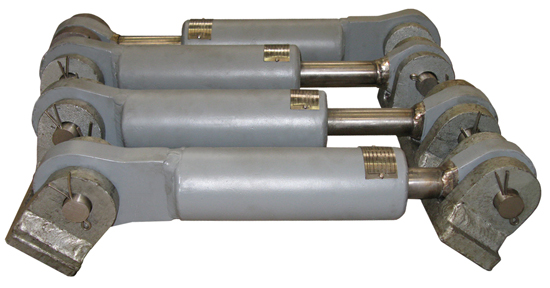

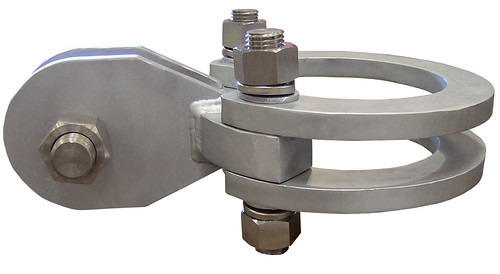

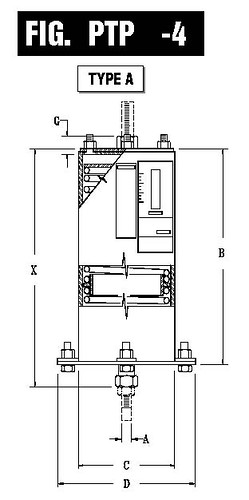

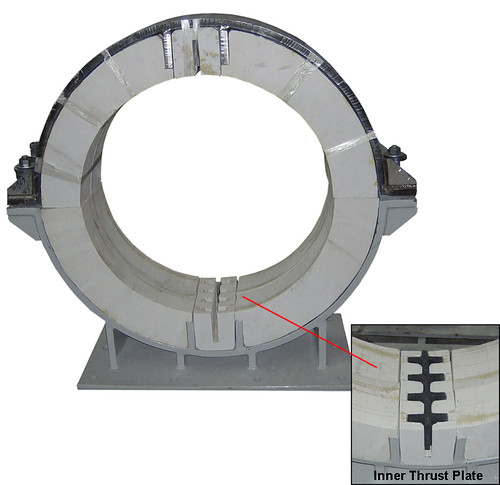

These A-36 carbon steel constants have a hot dipped galvanize finish and designed for an oil refinery. They have a single lug suspension and can support a piping load of 5,031 lb. The dimensions are 36 1/2″H x 21″L x 11 5/8″W. This type of spring support is designed to support the pipeline from above using a carbon steel clamp.

Want to learn more about constants? View a past constant webinar recording!