|

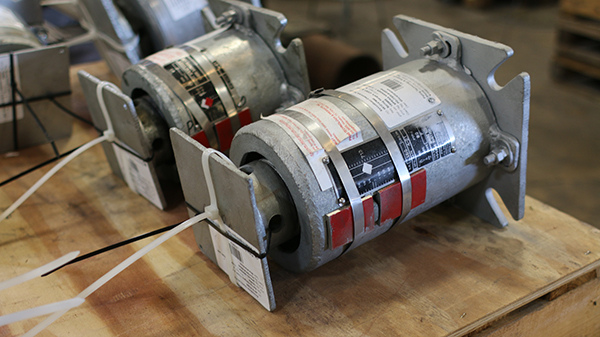

Piping Technology & Products designed these trapeze roller hangers for a food processing facility in Kentucky. Rollers are typically employed when axial movement at the support location results in swing angles exceeding 4 degrees.

The rollers are available in lengths ranging from 2-5/8″ to 16-3/8″ for pipe diameters between 4″ and 16″. Constructed with cast iron rolls and sockets along with steel roll rods, they ensure durability and adaptability for a range of applications.

The rollers are oriented horizontally for the suspension of pipes using two all threaded vertical rods and hex nuts for vertical adjustments, effectively accommodating longitudinal movement caused by thermal expansion or contraction. They are designed for load ratings ranging from 600 to 3,970 lbs.

Standard quality control inspections were conducted prior to shipment to ensure compliance with industry standards. Similar applications by Piping Technology & Products include:

- Wastewater facilities

- Food Service

- Bridges

- Cooling Towers

- Refineries

- Gas Plants

In addition to standard rollers, we offer machinable rollers made from specialized non-metallic materials, such as polyurethane and polyurethane foam. These materials can be custom-contoured to meet unique project specifications using our in-house manufacturing capabilities.

For larger roller assemblies, Piping Technology & Products provides complete customization options, including finite element analysis (FEA) to ensure the design meets the exact requirements of your piping system. Whether you need standard or customized solutions, our team is equipped to deliver quality products tailored to your application.

PT&P REF. ORIGINAL POST 04242017

Read More