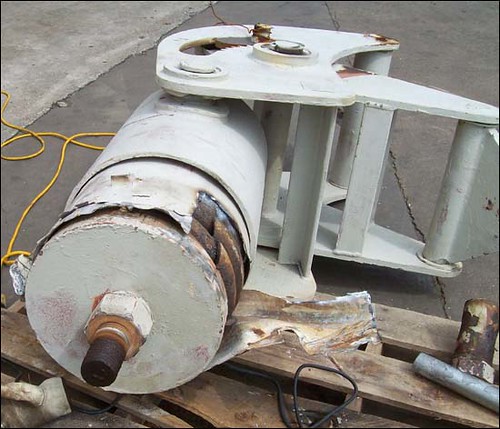

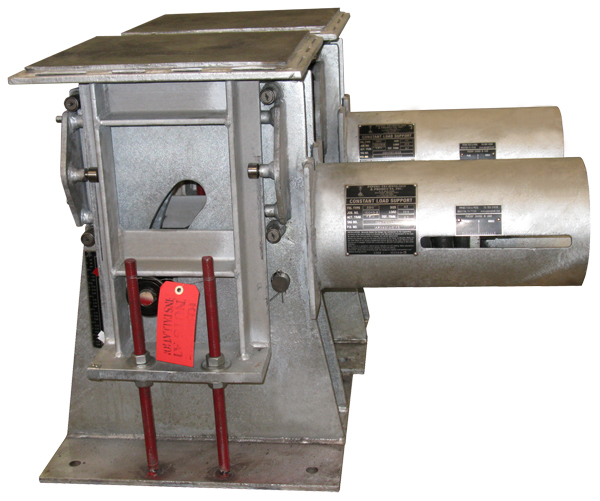

PT&P fabricated several big ton spring assemblies consisting of two different models for a refinery expansion project in India. The larger model has an operating load of 25,590 lb. and a design travel of .420″ up.

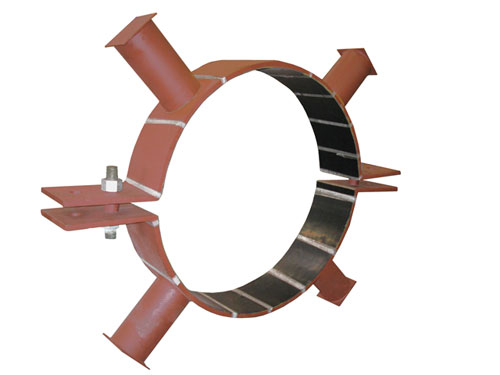

The smaller model has an operating load of 12,100 lb. and a design travel of .443″ up. The big tons will be utilized to support substantial vertical loads while simultaneously providing a large platform to accommodate axial movement of the piping system across the load flange. Low friction rollers are installed to reduce the sliding friction between the load flange and the bottom section of a pipe shoe.

Do you require big ton springs in your plant or refinery? Let us price them for you today!