Piping Technology & Products, Inc., designed and manufactured 150 custom embed plate pieces for Latin America’s largest gold producer. This gold mine is located between 3,500 and 4,100 meters above sea level in a northwestern province of Peru. The gold district is a 10 x 4 km zone of altered rocks with a belt of Tertiary volcanic that extends through Peru. Currently, precious metal is mined in three open quarries and according to rough estimates, the investments in the development of the gold mine amounted to about 150 million US dollars.

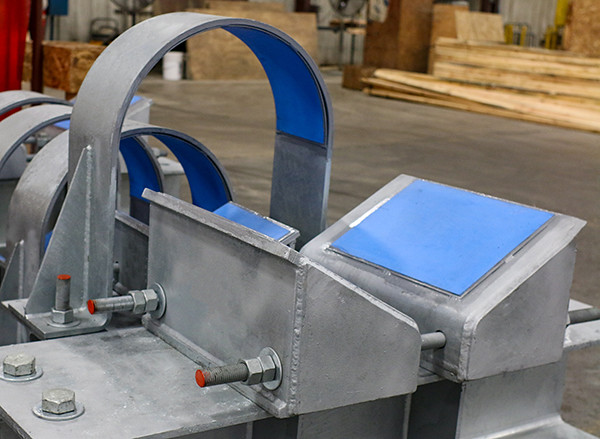

This project involved the production of 150, 93″ x 27″ x 1″ embed plates which required the use of 80,000 pounds of steel and anchors. The custom-designed, carbon steel, embed plates provided stability for the feed openings of four mineshafts reclaim tunnels and were scheduled to be put to use immediately. Our manufacturing process for these embed plates entails the use of a Nelson® stud welding machine to weld the studs to carbon steel plates. The carbon steel plates can be shaped to meet the rectangular mineshaft dimensions, then the studs are welded in place. Concrete is then poured around the outside of the embed plate shaft and the studs anchor the plates in place after the concrete sets. These assemblies can then be hot-dipped galvanized to protect against corrosion.

So, whether gold, silver, coal, precious gemstones, rock salt, gravel, oil shale, or some other valuable minerals are being mined, stable mineshafts are an important part of the mining process. PT&P has also manufactured embed plates suitable for large-scale projects for use in the foundations of the chemical, refinery, wastewater treatment, and power plants.

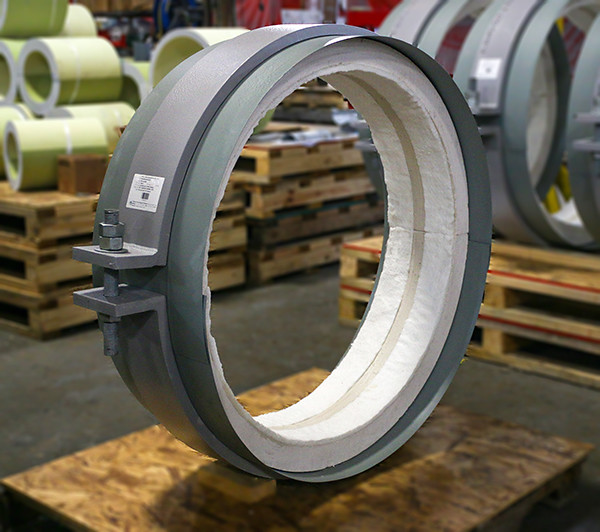

Piping Technology & Products and our subsidiaries have served many different mines in the United States, Africa, Europe, and South America. PT&P has extensive experience with key piping issues on mining projects such as wastewater treatment and abrasive media (slurry). In addition to the embed plates shown here, we have also supplied these products:

- Metallic, Fabric & Rubber Expansion Joints

- Pre-Insulated Pipe Supports

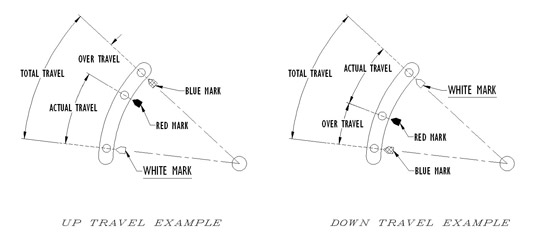

- Variable & Constant Springs

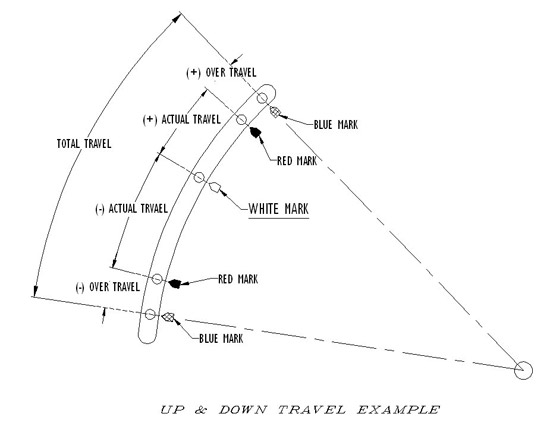

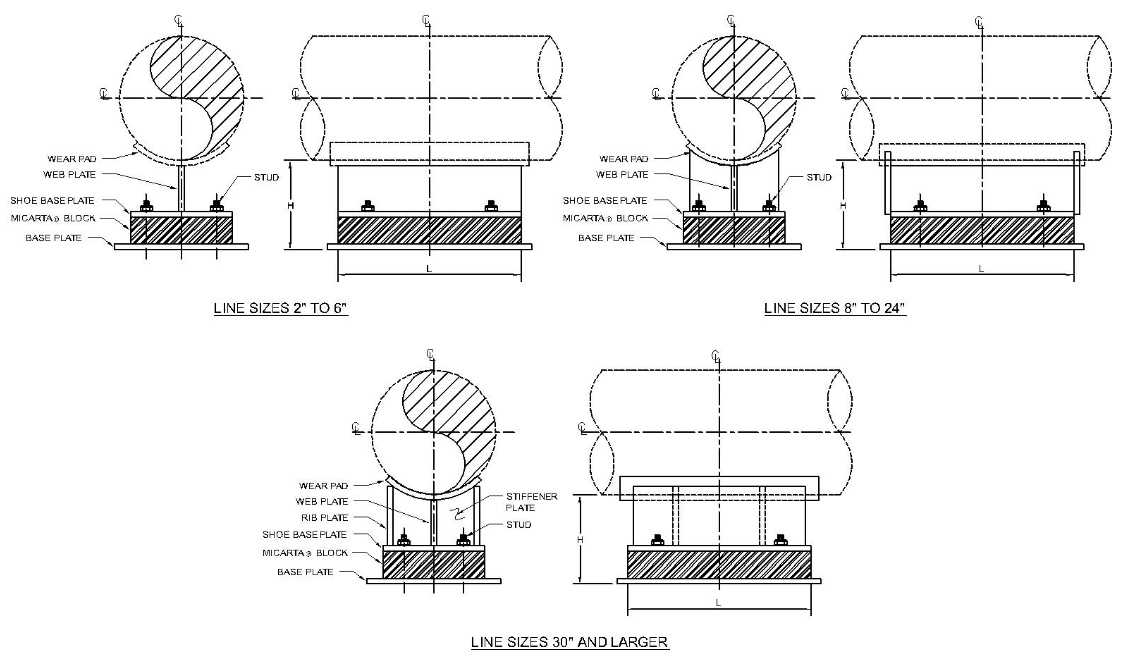

- Pipe Shoes & Hold-Down Clamps

- Slide Bearing Plates

- Field Services

In need of embed plates for an upcoming project? Request a quote today!

PT&P REF. ORIGINAL POST 03012001