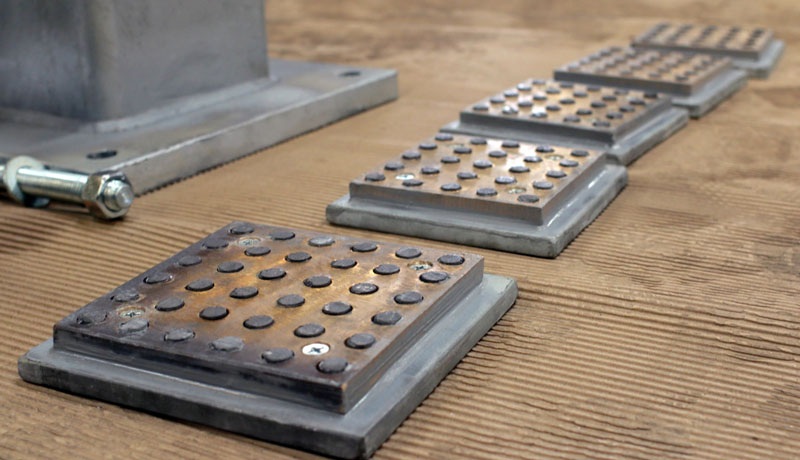

Bronzphite® Slide Plates

Bronzphite® is best suited for high loads, low-velocity applications and in places where the use of oil or grease is undesirable or unfeasible. Bronze plates impregnated with graphite will also handle temperatures up to positive 1100 degrees Fahrenheit. Additionally, Bronzphite® plates are suited for high-pressure systems with a load of up to 5000 PSI.

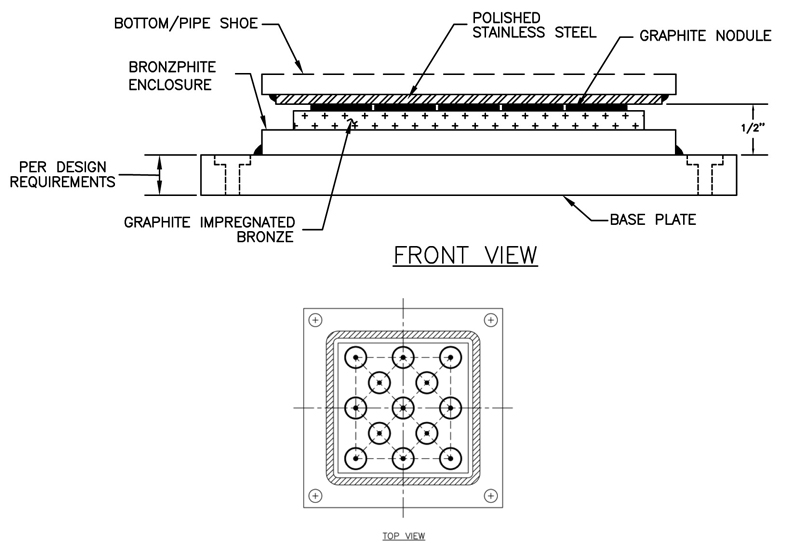

Bronzphite® Slide Plates General Diagram

Download Bronzphite® General PDF

The Bronzphite® plate is available in a standard configuration, which consists of the bronze plate bolted to a steel backing plate, allowing it to be welded in the field. The plate is self-lubricating and durable and is recommended for a variety of industrial applications, including pipelines, storage tanks, and dust collectors.

ASSEMBLY:

Standard Assembly:

Graphite impregnated bronze plate combined with a carbon steel backing plate, to be field welded. Loads up to 5000 psi, temperature: up to 1,100°F.

ADVANTAGES:

- Maintenance free

- Self-lubricating

- High wear resistance

- Has an extended life

- Lubrication does not deteriorate with wear

- Prevents accumulation of dust and debris

- Higher durability than standard graphite

- Withstands extreme pressures and high temperatures

APPLICATIONS:

- Bridges: Highway bridges, overpasses, railroad bridges.

- Architectural in Wood, Concrete or Steel: Cross beam and girder slip joints, roof slabs and corbels, vibration pads, airport hangar doors, domes.

- Industrial: Heat exchangers, dust collectors, heavy machinery, refinery equipment, wind tunnels, penstocks, vessels, pipelines, air preheaters, atomic energy applications, transmission towers, storage tanks, offshore drilling rigs.

ORDERING:

- Please specify the dimensions of the upper plate and dimensions of the lower plate. It is common practice that the upper plate is generally larger than the lower plate.

- Specify base plate thickness.